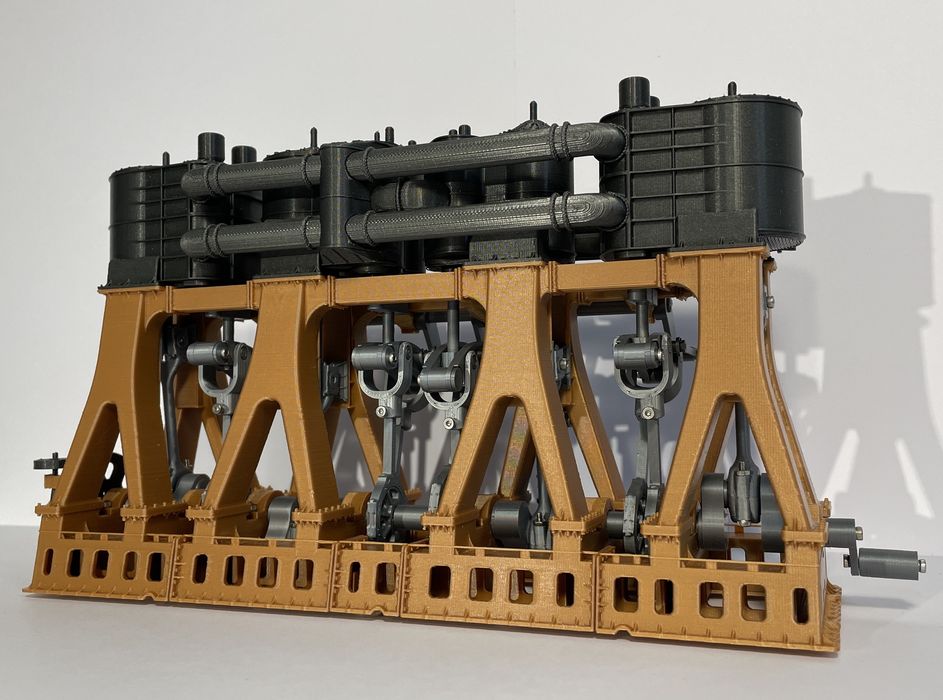

This week’s selection is the scale model Titanic’s Engines by Olivier Berlin.

This 3D model is exactly as its title: it’s a scale model of one of the ill-fated Titanic’s coal-fired steam engines. What’s notable is that this model is accurate. Berlin explains:

“This is a historically accurate model of the Titanic’s starboard triple expansion steam engine. When fully assembled, it is approximately 550 grams heavy, 25cm long and 15cm high. This translates to a scale of roughly 75:1. All the cylinders, valves and the crankshaft are able to turn over.”

As a bonus, this model actually works! Well, it doesn’t require coal, but in fact runs on air pressure, which can be provided by air pressure — if, Berlin suggests, “you use the right kind of PLA and put a lot of extra effort into the model.”

If you’re thinking this 3D model is pretty straightforward, you’re incorrect. The design involves 3D printing in excess of 200 individual parts for assembly. That’s a lot of printing, and you must do it perfectly. Berlin explains:

“Warning: This is by no means an easy to print or easy to assemble model. You need a perfectly calibrated 3D printer, perfect bed adhesion, lots of experience with your slicer and at least a week or two of time to make everything run smoothly. Every single part needs to be manually sanded, adjusted or glued in some way or another.”

And that’s just the printing; you’ll have to assemble the parts together. Berlin explained that for him — the person that designed the model — it took a week just for assembly.

There are a few non—printable parts required for this project, mainly M2 nuts and bolts. Of course, you’ll also need a considerable amount of sandpaper.

Berlin includes a warning in his Cults3D listing asking that if you’re not up for all this effort, don’t purchase the model.

That said, you can own this 3D model and attempt to build the incredible Titanic Engine from Cults3D for a low US$10. That’s an amazingly low price for a model of this complexity, which apparently took Berlin over 250 hours to research and design. That’s equivalent to over six weeks of full-time effort.

The Titanic’s Engines are easily a great bargain.

Via Cults3D