Metal Powder Works has developed an incredibly straightforward and energy efficient method of producing metal powder that can be used in additive manufacturing.

The Pittsburgh-based company was founded in 2017, but launched their products only in 2021. Their product is metal powder, which is produced by many companies. However, the difference is in how the powder is created.

Presently there are two methods to create metal powder.

The first method involves the use of a plasma. Into that high temperature environment is introduced metal, which swiftly vaporizes. As the gas cools, metal particles precipitate. Due to the randomness of the process, particles are of various sizes. Afterwards, these particles are sifted to isolate the particles that have the required diameter for the application, which in our case is additive manufacturing.

Unfortunately, it turns out that typically less than 30% of the particles are the right size, and the rest is discarded or sent for recycling.

The second process was recently introduced by 6K Additive, which uses a microwave technique to heat the metal. The microwave approach allows them a much more precise control over the heating, and thus the particle yield is far higher. Because of the higher yield, their process is far more energy efficient.

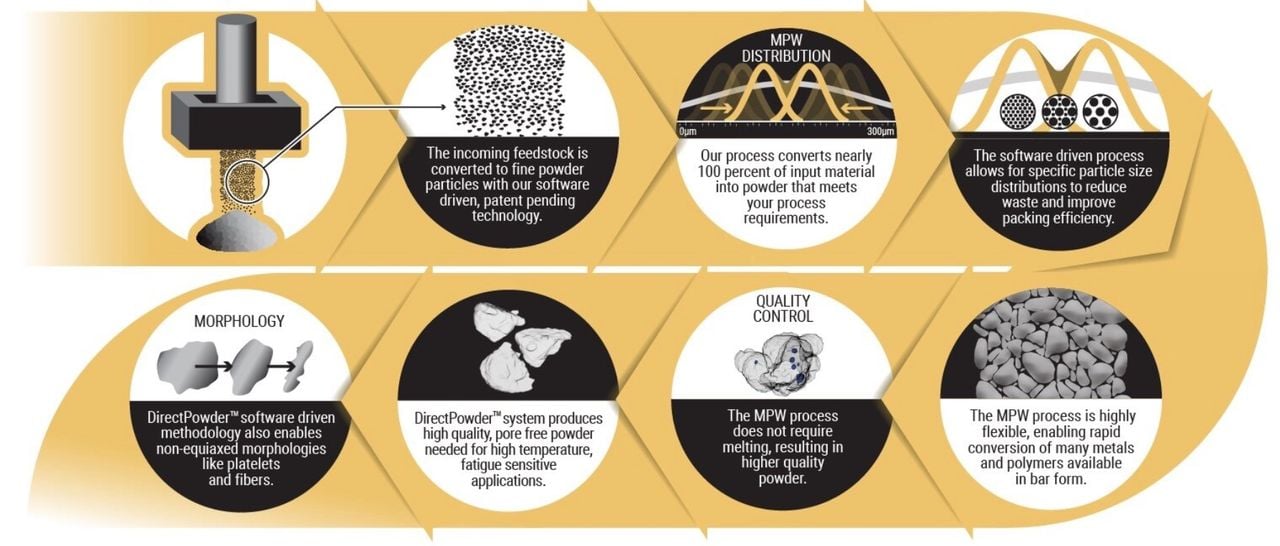

Enter Metal Powder Works, which has a third approach for producing metal powder.

Surprisingly, the MPW process does not involve heat at all: they simply grind metal to produce powder mechanically.

They don’t disclose details of how this grinding process actually works, but the results are impressive. They claim 95% yield, which is comparable to 6K’s – however, less energy is used, and thus one could consider MPW’s process sustainable, particularly over plasma-based powder production.

What’s really interesting is that MPW can apparently not only control the size of the particles, but their geometry as well. They have a “software-defined process” that can create a “wide range of pre-defined part shapes”. This includes particle shapes that would be ideal for additive manufacturing.

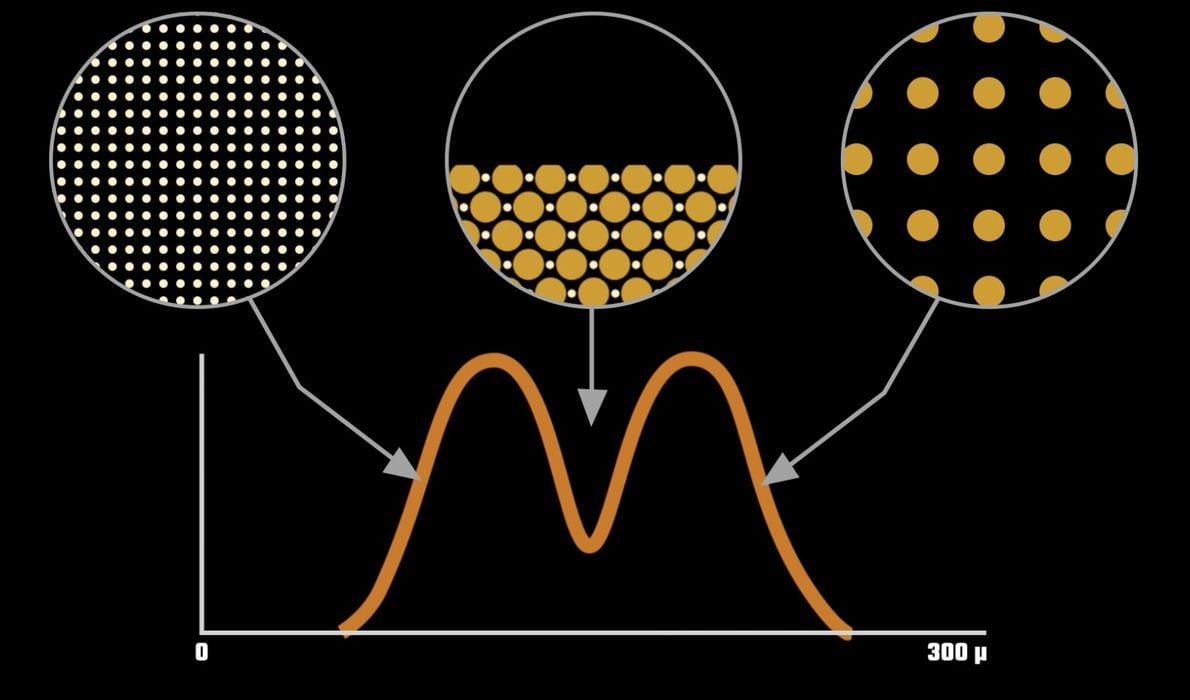

Amazingly, they can actually create powder that has a mix of shapes, and this can be used to create densely packed powder by combining large and small particles as seen here.

Currently the company produces 075-T6 Aluminum, 6061-T6 Aluminium, and C14500-H02 Copper, but it would seem clear that their mechanical process would be compatible with many other metals. However, the metals above are relatively soft, so it would be interested to see if they can produce powder made from harder materials.

Metal Powder Works has one machine running in Texas, and has plans to open up another six machines, some of which may be running by now.

I’m interested to see how both Metal Powder Works and 6K Additive shake up the metal powder industry. It could be that lower-priced metal powder — and consequently cheaper 3D printed metal parts — are on the way.