Fused Form is a small company from Colombia that makes a large 3D printer.

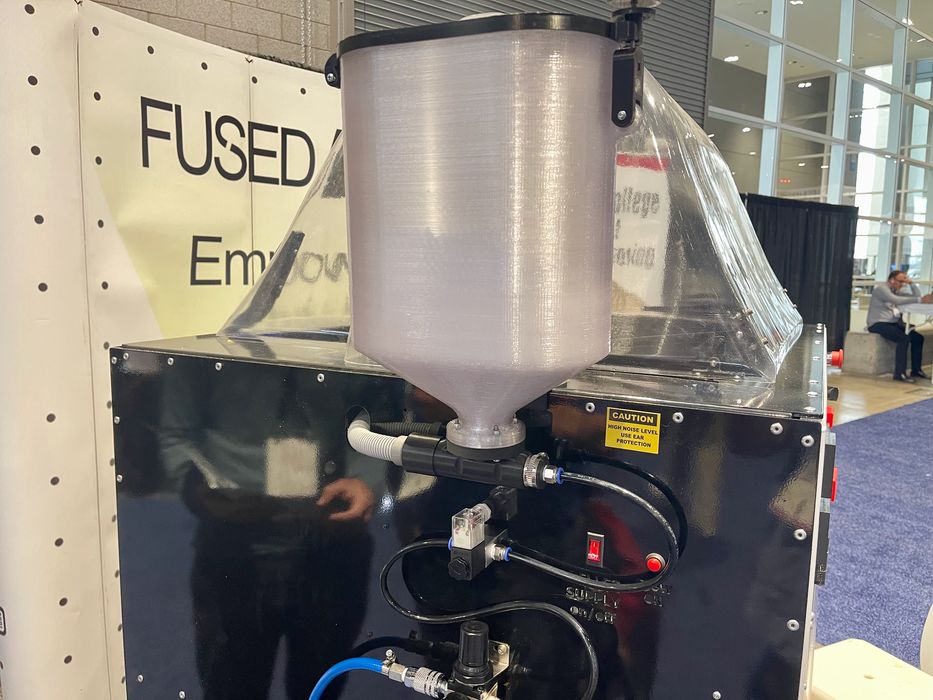

Our first encounter with their work, the new FF-Pellet 600+ 3D printer, certainly piqued our interest. Unconventional in its design, this device opts for pellets as its printing medium, a significant departure from the ubiquitous, yet pricier filament materials.

The Rising Trend of FGF Devices: Embracing Affordability and Efficiency

The use of pellet material, as seen in FGF devices, is gaining popularity. With a price point up to 10X cheaper than filaments, the financial benefits are clear. The convenience factor is also noteworthy, as keeping the hopper filled with pellets is far less laborious than continuous filament spool changes.

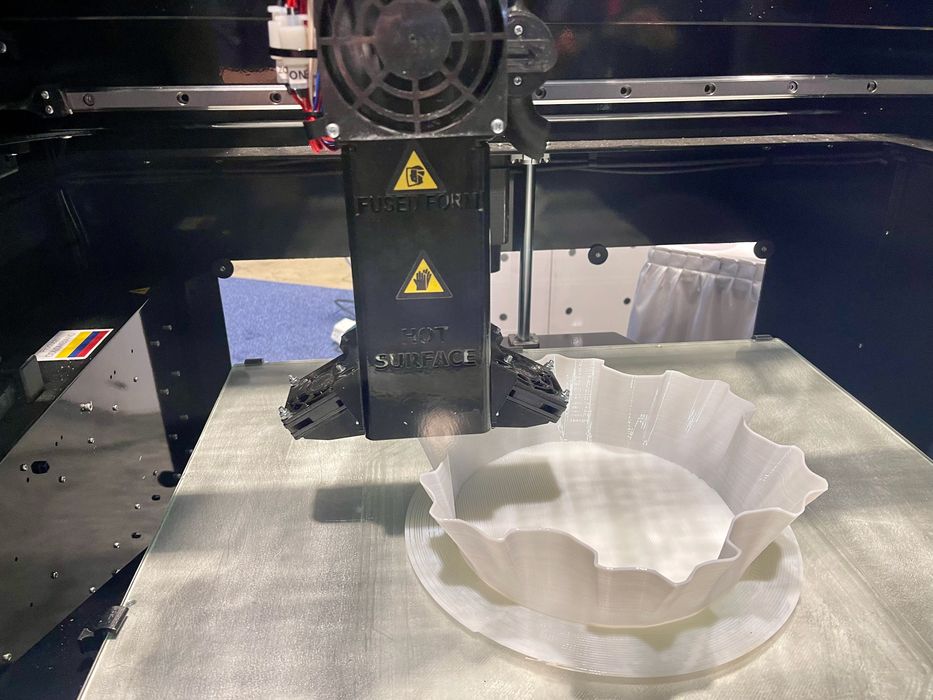

Dwarfing typical 3D printers, the P600 is almost as tall as a smaller person. Its impressive build volume of 600 x 600 x 600 mm is much larger than typical 3D printers. Yet, the P1000, another product in Fused Form’s portfolio, outdoes it with a staggering build volume of 1100 x 1100 x 1300 mm.

Balancing Speed, Material, and Cost: The Fused Form Advantage

With such large print volumes come two concerns: the duration of print jobs and the expense of materials. The cost issue is addressed by the economical nature of pellet materials. But what about the speed?

Surprisingly, the P600 delivers a swift 3D print speed of up to 200mm/s, around 4-5X faster than your average desktop 3D printer. The P1000 outpaces it, offering a rapid print speed of 300mm/s to accommodate its larger build volume.

A variety of materials can be handled by these machines, thanks to their enclosed design. This enclosure retains heat, effectively reducing warping effects. The P600’s hot end can achieve 300C, while the P1000 can reach a scorching 450C, unlocking access to numerous engineering materials. Both machines boast a material throughput rate of 400g per hour, a significant figure translating to 3D printing almost half of a 1kg spool each hour.

Adding to their appeal, these machines are remote-operable and feature an onboard camera system for real-time monitoring. They come with a Simplify3D license, recently upgraded with a “live preview” feature that aligns perfectly with Fused Form’s offerings. UltiMaker Cura can also be used for print job preparation.

Affordability Meets Performance: The Fused Form Pricing Strategy

But the real showstopper for both the P600 and P1000 is their price tags, substantially undercutting competitors in the large-format enclosed 3D printer market. For instance, the P600 has an attractive starting price of just US$17,000, nearly half the price of similar-sized models. Consequently, these printers are catching on with budget-aware buyers, especially universities and research institutes.

Despite Colombia’s geographic distance from the major 3D printing markets, Fused Form has cleverly adopted a network of regional resellers to market their products, leveraging local knowledge and support. As this network expands, we anticipate seeing more of Fused Form’s presence in North America and Europe.

Via Fused Form