Charles R. Goulding, Jacob T. Nolan and Preeti Sulibhavi discuss TikTok sensation Emily Yarid, known as Emily the Engineer, and the intersection of creativity and engineering.

“Start getting your hands dirty. Build things, get your hands on tools,” Emily Yarid, also known as Emily the Engineer, is quoted as advising anyone interested in engineering. This includes 3D printers.

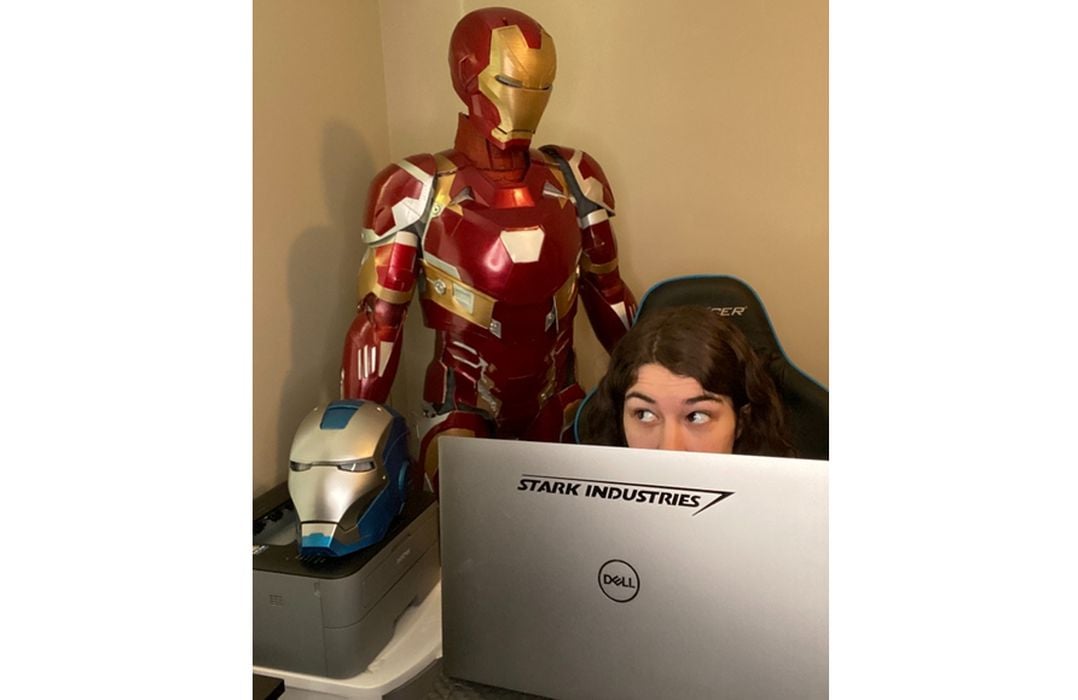

For those of you not familiar with Emily Yarid, or Emily the Engineer, she is a mechanical engineer and a TikTok sensation who has built three versions of the iconic Marvel superhero suit, Iron Man. She graduated from Clemson University in December 2023 and learned some of her Iron Man-building skills there. She started the project when she was 14 years old and used computer-aided design software and 3D printing to create her suits. She has over 60 million views on her video of her building a blue Iron Man suit.

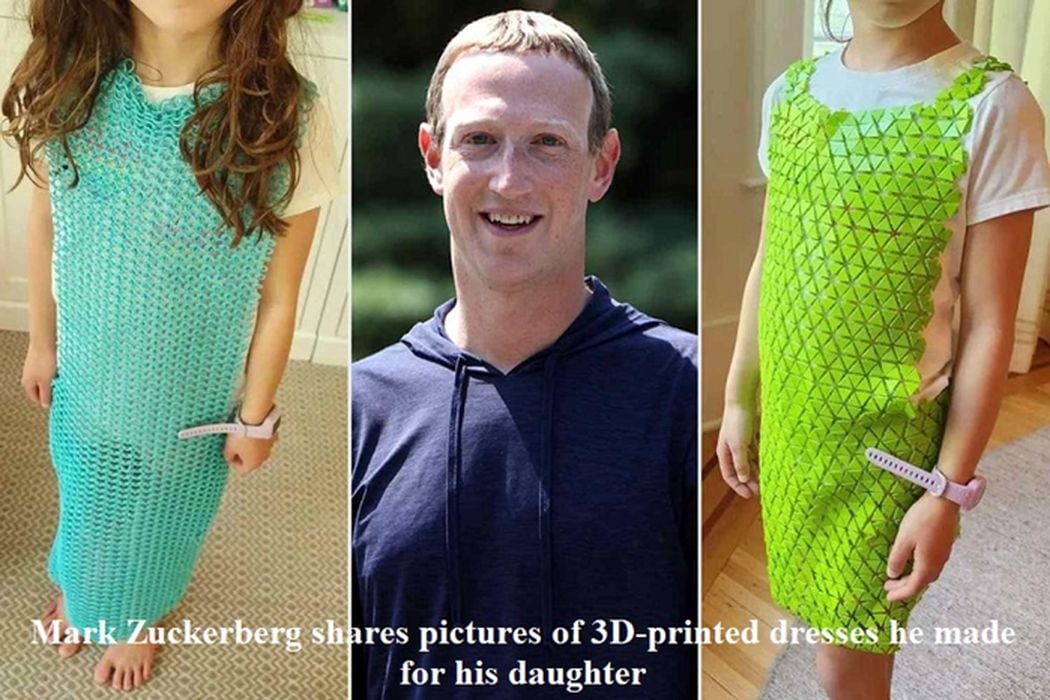

More recently, this past Spring, Emily’s YouTube videos helped inspire Mark Zuckerberg, CEO of Facebook, to create 3D printed dresses with both of his daughters. In fact, Zuckerberg revealed to Yarid on social media, “Thanks! Your videos got us started on our journey into 3D printing, and I’m grateful for all your help along the way!”

3D Printing and Textiles

The 3D printing industry is no newcomer to the textile business. Whether it is the newly fashionable and functional “mushroom leather,” or creating versatile yet durable products using Jute, 3D printers are able to integrate a broader range of materials and create intricate designs and patterns that would not be as easy to do using traditional manufacturing techniques. The added benefits of 3D printing textiles, especially using the materials mentioned above is the eco-friendly nature of the materials. Mushroom leather is a viable alternative to animal leather and plastic, while Jute is a thick, coarse fiber mostly composed of plant materials like cellulose (plant fiber) and lignin (wood fibers) – a great alternative to manmade plastic bags as well.

3D printing is also making inroads into high-fashion and haute couture as well. The fashion giant, LVMH, which owns household names like Tiffany & Co, Fendi, Christian Dior and Givenchy is increasingly relying on 3D printers to advance its innovative efforts. In fact, Louis Vuitton recently used 3D printing in its Capucines collection, which features collaborations with world-renowned artists. For Bolivian American artist Donna Huanca’s creation, washes of navy, royal blue, and milky white were 3D printed onto the white leather of the iconic Capucines handbag.

Emily the Engineer

Yarid’s first project, which she started when she was 14 years old, was a red and gold Iron man suit made from Styrofoam and hot glue. It brought attention to her engineering skills and ability to relate them to the general population in a fun and educational way. This is a big win for the STEM movement and for the 3D printing industry as well.

Yarid said her decision to pursue engineering started to come together around the time she was in 10th grade at Westminster Schools of Augusta. Anytime she wondered how a tool worked, her father would show her. A physics teacher encouraged her to move in the direction of engineering.

“And then, eventually, ‘The Avengers’ movies rolled out,” Yarid said. “I was a huge nerd. I was like, ‘Yes! This is awesome.’ I saw people building little Iron Man suits out of foam. So, I did– out of foam and hot glue. That was super fun. And that made me want to build stuff.”.

Her father, Don Yarid, is also a Clemson graduate and working as an electrical engineer.

The Research & Development Tax Credit

The now permanent Research & Development Tax Credit (R&D) Tax Credit is available for companies developing new or improved products, processes and/ or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

It is not every day that a young engineer, inspired by superhero movies, motivates the CEO of one of the world’s leading social media platforms. Emily Yarid is an example of how science and technology can impact the lives of so many people in a fun and educational way. The 3D printing industry can take the baton from here and increase its social media presence as well as its STEM involvement.