Charles R. Goulding & Andressa Bonafe look at the use of 3D printing technology in the high-end fashion industry.

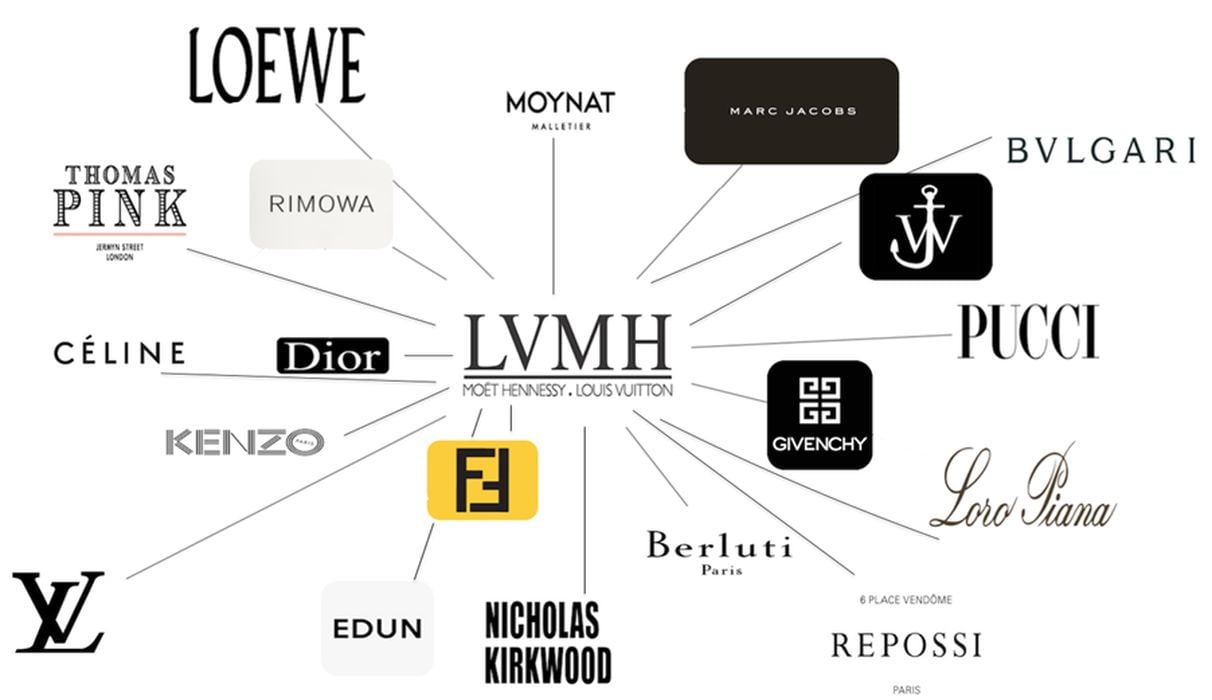

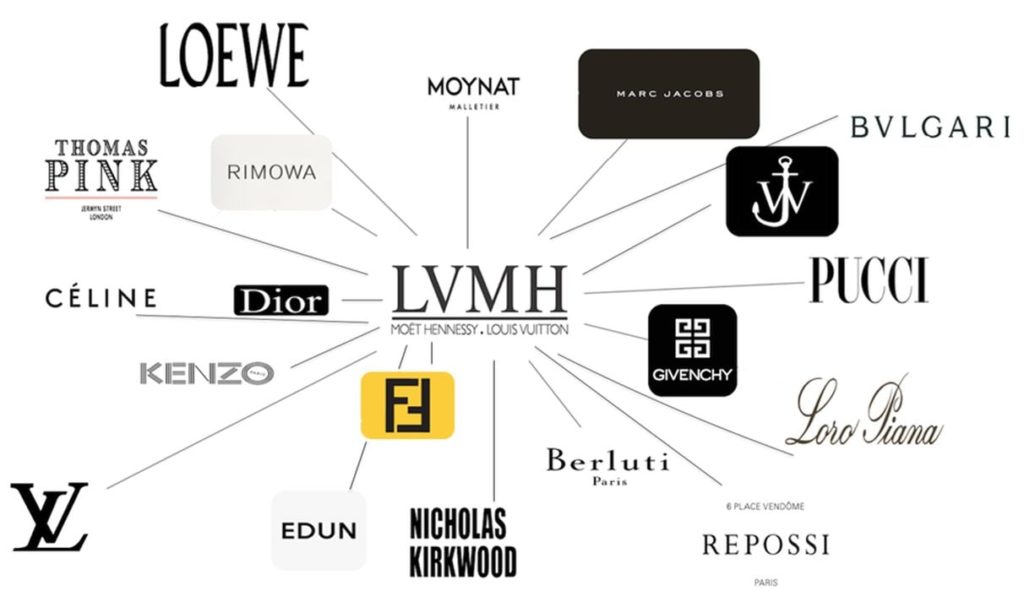

A family-run group founded in 1987, Louis Vuitton Moët Hennessy (LVMH) is home to 75 iconic maisons that create a unique combination of heritage and modernity. With reported sales of €44.7B (US$50.7B) in 2020 and 5003 stores around the world, the French group is present in all major sectors of the luxury industry, from wines and spirits to watches and jewelry.

Currently employing over 150,000 people across the globe, LVMH is headed by Chairman and CEO Bernard Arnault, who was the richest man in the world in May 2021. The group owns household names like Tiffany & Co., Fendi, Christian Dior, and Givenchy along with a growing number of new brands.

While valuing tradition, the LVMH model stimulates creativity and excellence. Eco-design and the incorporation of innovative and environmentally-friendly materials are priorities to the group’s maisons, which increasingly rely on 3D printing to advance their innovative efforts. The following sections present examples of how LVMH brands in the fashion & leather goods and watches & jewelry segments are integrating additive manufacturing.

Fashion & Leather Goods

Over the past decade, 3D printing has made its way into the fashion industry, helping push the boundaries of design and functionality. From record-breaking footwear to smart fabrics, additive manufacturing plays an increasingly central role in a variety of innovative efforts.

The luxury industry is no exception and neither are LVMH brands. In fact, Louis Vuitton recently used 3D printing in its Artycapucines collection, which features collaborations with world-renowned artists. For Bolivian American artist Donna Huanca’s creation, washes of navy, royal blue, and milky white were 3D printed onto the white leather of the iconic Capucines handbag.

Christian Dior went even further and used 3D printing to create a pop-up store in Dubai. Designed in collaboration with the Italian firm WASP, the space was crafted with natural materials, including clay, sand, and raw fibers.

LVMH brands are also stepping into the metaverse, a trend that promises to create new 3D printing opportunities. In 2020, Marc Jacobs launched a collection of clothes designed for Animal Crossing avatars. In January 2022, 3D SaaS company Threedium announced their participation in La Maison des Startups LVMH. Part of the group’s Open Innovation Ecosystem, the accelerator program aims to increase collaboration between startups and LVMH maisons. Threedium’s participation points to an increased focus on 3D and AR solutions.

As the market for non-fungible tokens (NFTs) grows, 3D printing stands out as the perfect medium to bridge the gap between the digital and physical worlds, creating innovative hybrid experiences.

Watches & Jewelry

Additive manufacturing has also found its place in the jewelry design industry, particularly in combination with the lost wax casting method. Through the generation of detailed molds, 3D printing allows for the creation of customized and increasingly complex pieces while preserving cost-efficiency.

In January 2021, LVMH completed the acquisition of Tiffany & Co. for US$15.8B. Known for its signature elegance, craftsmanship, and style, the American jeweler has strived to combine time-honored techniques and modern technology. At the 17,000-square-foot Jewelry Design and Innovation Workshop in New York City, a team of jewelers, CAD designers, engineers, and quality-assurance experts use parametric design and additive manufacturing to expand upon Tiffany’s legacy of innovation.

Other members of the LVMH group have also integrated 3D printing into their processes. Roman luxury house Bvlgari has used additive manufacturing and the lost wax technique to create unique pieces of jewelry. Similarly, Swiss watchmaker TAG Heuer has incorporated 3D printing for prototyping and testing.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

LVMH brands illustrate the diversity of 3D printing applications in the luxury industry. From jewelry design to eco-friendly pop-stores, additive manufacturing has created new opportunities to advance the group’s unique mix of tradition and innovation.