Researchers have used 3D print technology in an innovative manner to enable human cartilage tissue engineering.

Bioprinting is a very tricky science. While it may seem straightforward to deposit living cells into the desired shape, that’s not how it works. Cells are not building material, and they tend to flow like a liquid. In order to bioprint tissue the typical approach is to build some sort of “scaffold” upon which the cells are deposited.

This enables some control over the shape of the resulting biostructure.

The researchers here were interested in identifying ways to bioprint human cartilage. Cartilage is often damaged through accidents, and this can affect movement for a lifetime.

Normally cells are bioprinted along with a scaffold as described above, but that doesn’t always work in the case of damaged cartilage. Cartilage often needs repair rather than replacement.

Their approach is quite interesting. Instead of using large-scale scaffolds that represent the entire structure, they instead opted for a “micro scaffold”.

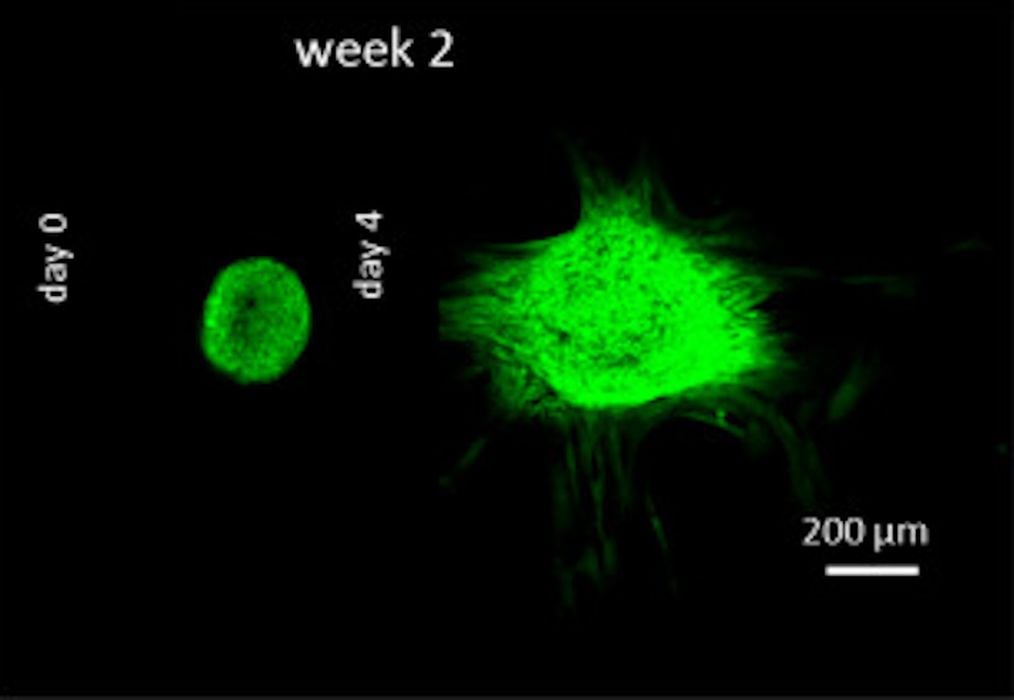

The micro scaffold geometry is basically a spheroid of small diameter. The idea is to 3D print the spheroids, and then have them contain the cartilage cells.

Over time the cells multiply and grow into properly formed cartilage. Meanwhile, the spheroid gradually breaks down and disappears entirely, leaving just the cartilage behind.

There’s a problem, however. When building larger biostructures with this approach there are issues with compaction and cell adhesion.

The new approach attempts to overcome these issues by using a kind of hybrid approach involved both standard and spheroids. Basically, the cell-infused spheroids are inserted into a scaffold, which holds things together in a way to minimize the negative effects.

The 3D printing of spheroids was done with the two-photon process commonly used to produce extremely small objects. Because of the small size, the researchers were able to produce 5000 spheroids per day. The spheroids had a diameter of only .35mm, with struts of 0.035mm.

The work was successful, as the researchers explained:

“The third tissue engineering strategy offers unprecedented opportunities by unifying scaffold-free and scaffold-based strategies. We have recently shown the possibility to create multiple building blocks by integrating single spheroids within microscaffolds. For this new strategy to become a breakthrough in tissue engineering, it is not only important to demonstrate that high number of S-SPHs can be rapidly produced, but that they possess unaltered stemness potential and robust fusiogenic properties. This is a strong prerequisite, since building blocks with poor, unreproducible or uncontrollable self-assembly properties cannot be used further as building blocks to engineer large tissue structures.”

Via Science Direct