As the manufacturing industry comes together again, digital processes like additive manufacturing are taking up more space.

The last time I was at Chicago’s major conference venue, McCormick Place was fully booked up with a massive industrial gathering. IMTS may not have happened in person as planned last year, alas, but 2021 is seeing industry events reconvene and so FABTECH 2021 brought a large showing — conveniently co-located in the same building as RAPID + TCT.

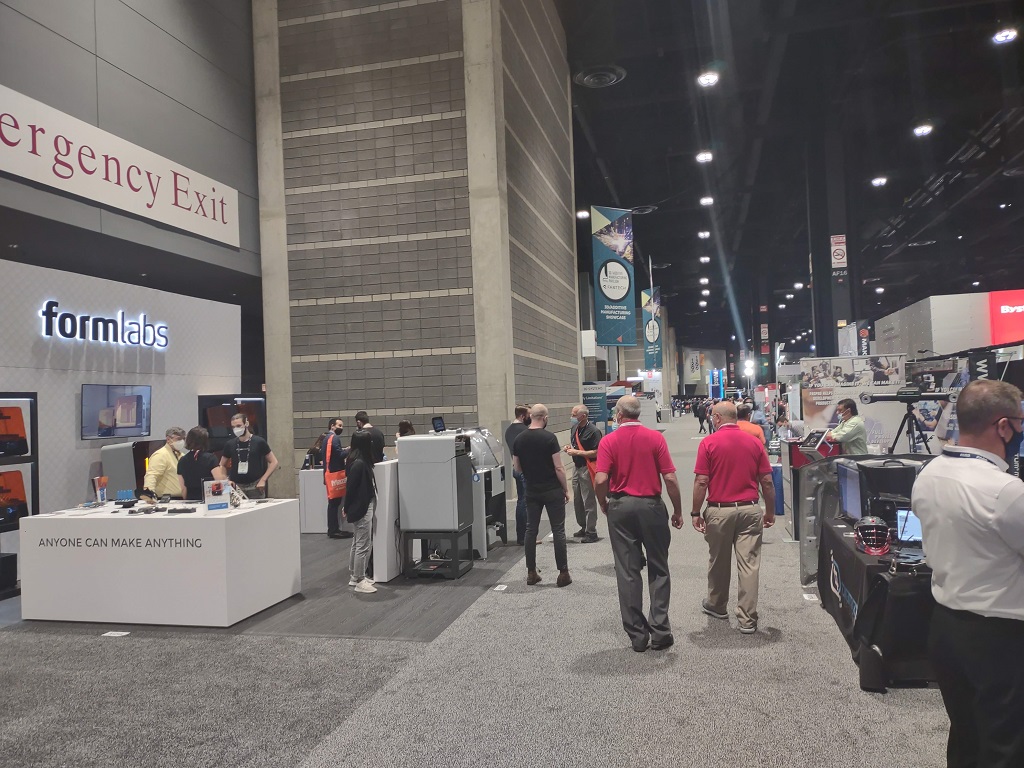

Naturally, most of the 3D printing was found at RAPID + TCT. But I also registered for FABTECH because the show featured a corridor of additive manufacturing technologies.

3D Printing at FABTECH 2021

A glance at the exhibitors list for FABTECH showed some notable overlap with companies showing a hall over at RAPID + TCT. In fact, many of the RAPID + TCT conversations I had were with those who noted that their team was split between the two booths to catch both audiences.

Still, there’s a difference — as we also observed at the recent Ceramics Expo — between visitors to shows.

RAPID + TCT is dedicated to additive manufacturing; it’s all 3D printing, all the time. Those 3D printing companies exhibiting at the Ceramics Expo were able to touch base with a very specific user base. Conversations there with potential new customers still included things like explaining just what “post-processing” is.

The FABTECH crowd is somewhere between those two. Tech-savvy, manufacturing-focused — but generally more familiar with a CNC machine, injection molding setup, or sheet metal folding than with a 3D printer.

As with IMTS, though, which has for several editions now featured dedicated floor space for additive manufacturing, FABTECH brought in a focus on newer manufacturing processes. This included scheduled expert presentations and knowledge sessions as well as two aisles of exhibit space.

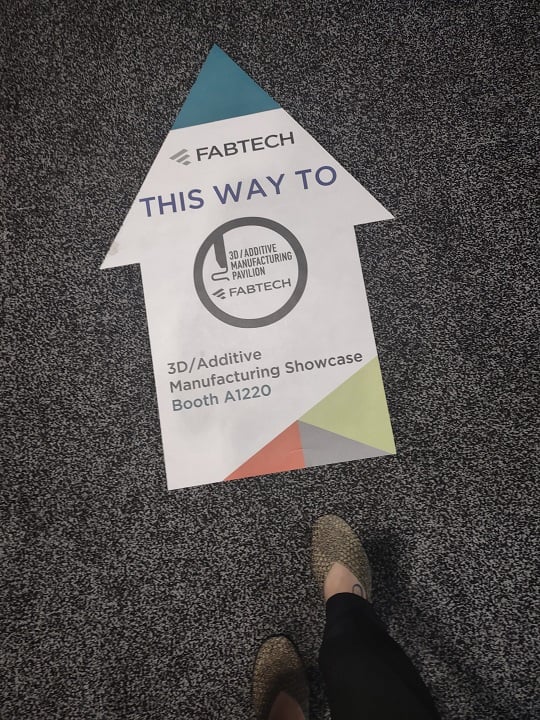

It was hard to find, honestly. Entering one of the halls dedicated to FABTECH, I unfortunately turned right to explore rather than left. It took handy arrows on the floor to point me the right way.

Compared to the rest of the FABTECH space, the AM area was relatively small. Still, it was two full aisles in a larger hall and there was plenty to see.

With the overlap with RAPID + TCT exhibitors, many of whom I had spoken with at length the day before, I didn’t stop for many conversations at FABTECH. I did have a nice catch-up with Essentium, though, as that team were proud to display their latest introductions and shared some plans ahead (key word: growth).

3D Printing Exhibition Strategy

Strategies certainly differ when exhibiting at different events.

For all-additive shows, like RAPID + TCT, companies can connect with ecosystem partners, highlight use cases, capture dedicated media attention, focus on expert-driven learning opportunities, share knowledge, network, and advertise job openings. Face time at these events is often with like-minded individuals familiar with the industry and often with further niche expertise.

Broader-scope events like FABTECH offer different opportunities. As additive manufacturing continues to take up more space in the overall manufacturing industry — with companies like HP, for instance, often highlighting the opportunity for 3D printing within the overall multi-trillion-dollar space — it only makes sense that that comes into play for manufacturing shows as well.

Here, more of a use case can be presented for bringing additive into existing manufacturing installations, highlighting the realities of today’s industrial 3D printing capabilities. Potential new customer connections can be made, with the understanding there will be more hands-on education to be done.

Having a booth at both RAPID + TCT and FABTECH this year was a strong move this year. This could have been enabled in part by marketing budgets that didn’t have as many travel plans over the last 18 months, along with the general growing appetite for digital manufacturing across the board.

Via FABTECH