Charles R. Goulding and Preeti Sulibhavi look at how an upcoming spin off could make use of 3D print technology.

In a recent Barron’s article published on May 9, 2022, Fortune Brands was featured because of its varied business segments and a proposed spinoff, likely to occur in 2023. The spinoff will split Fortune’s cabinetry division into a publicly traded company with Fortune’s shareholders as owners.

Fortune Brands Home & Security, Inc is a leader in home and security products with revenues of about US$7.7B and 28,000 full-time employees globally, in 2021 alone.

Contrary to what you may be thinking, the spinoff is not happening because Fortune wants to highlight the spectacular results of its cabinetry business, but rather because in 2021, cabinet sales grew 16% slower than Fortune’s other divisions. Otherwise said, cabinetry was pulling down the overall valuation of Fortune’s other business segments.

The company is comprised of many leading brands, some can only be recognized by their product names, like Moen for faucets.

Woodwork & Cabinetry

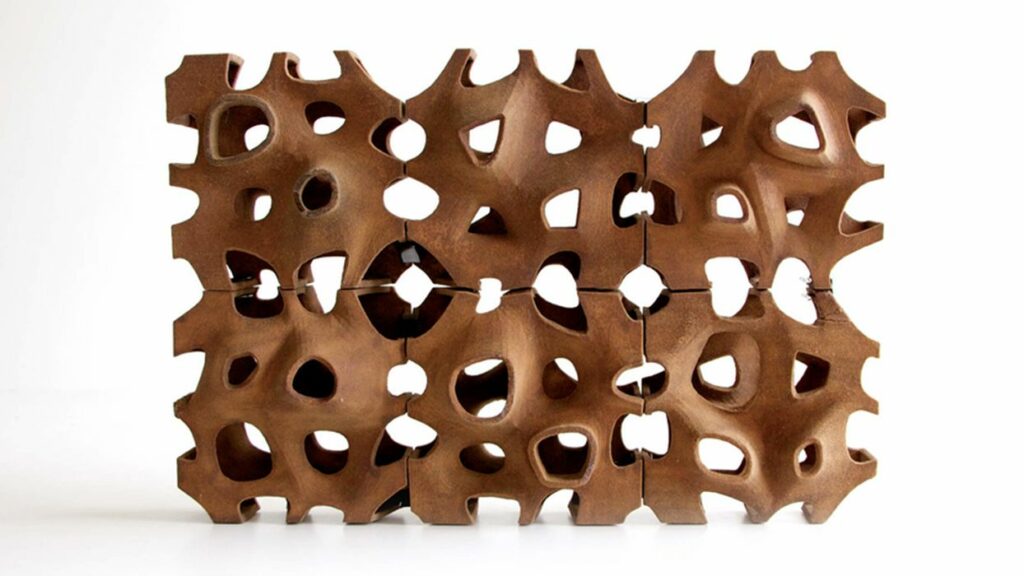

We have previously written about how 3D printing can be the future of the woodworking industry. In that piece, we explained how previously there have been attempts to 3D print with wood however, in reality, the materials were only 30-40% comprised of wood fibers. These results also lacked the traditional grain and feel of wooden materials. Utilizing Desktop Metal technology, Forust (a sustainable 3D printing company) can produce parts that have the aesthetic and the feel of traditionally manufactured wood materials.

Forust has leveraged additive manufacturing with its own proprietary wood-based solution that utilizes waste products from wood and paper products. More specifically the proprietary formulation makes use of the primary waste products from woods and papers, those being lignin and cellulose dust (sawdust).

This technology works by deposition of binding agents over a powder layer (in this case sawdust and lignin) of material in a repeated fashion until the part is completed. Using this technology Forust is capable of reproducing the grain structure of any number of exotic woods while also being capable of producing grainless wood pieces.

Plumbing Components

Any home requires indoor plumbing and with that comes many different parts and connectors. Plumbing components include piping, connectors, threaded caps, etc. There is plumbing equipment as well: sinks, toilets, baths, showers, kitchen plumbing and more. All of these items are part and parcel of modern life.

There are now more ways to 3D print plumbing parts and components than ever. Everything from valves to pumps can be 3D printed efficiently.

3D printed product designs are flexible and can solve many mechanical needs. For example, a 3D printer can make pipe connectors. If the piping is running at a 45-90 degree angle and the connectors don’t work efficiently, then 3D print your own custom connector. These connectors hold the pipes in place and allow for rapid and simple fixes.

Security

Physical security is something everyone takes seriously. Whether you are a homeowner or you run a business, security is critical in today’s world.

There are many ways in which 3D printing can enhance security measures and products. Physical security is a highly complex, multifaceted challenge. It encompasses all of the physical measures designed to safeguard personnel; to prevent unauthorized access to equipment, installations, material, and documents; and to protect against numerous threats, such as theft and damage. The diversity of potential menaces to physical security calls for multilayered, flexible solutions that use innovative technology to keep up with ever-changing risks.

Before the pandemic, physical security had a 2020 projected growth rate of 6.5%, from US$103B to US$110B in sales. Despite flattened sales due to COVID 19, innovation within the field has continued apace. One underlying theme is that physical security technology builds on top of many other current technologies, including artificial intelligence, cloud, drones, sensors, and improved cameras.

The Research & Development Tax Credit

Higher costs for technical labor and materials used in prototypes will generate higher R&D tax credits.

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

A Good Fortune

The spinoff business segment focusing on cabinetry and woodwork was done to carve out a lesser-performing business segment to improve Fortune’s valuation. Hopefully, if the spinoff utilizes some 3D printing resources it can rebrand itself as one of Fortune’s most fortunate brands.