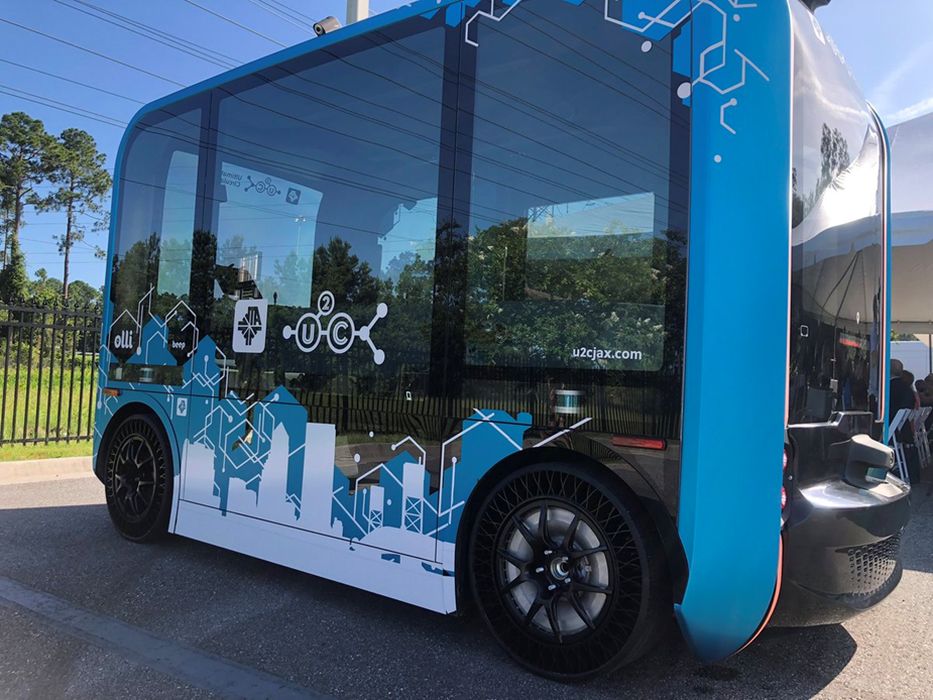

Olli 2.0 Autonomous Vehicle with Goodyear NPTs [twitter.com]

Charles R. Goulding and Randall Rothbort examine the development of puncture-proof 3D printed vehicle tires.

Tires have existed relatively unchanged for decades, with few new innovative technologies being implemented.

However, 3D printing offers tire manufacturers a significant new technology that can revolutionize the industry, including airless tires, unique treads, smart technology, and vastly improved manufacturing methods. The manufacturers who continue to incorporate the technology and innovate stand to benefit by offering unique products with vastly improved quality and functionality.

One company making significant use of 3D printing is Goodyear, which is testing the first 3D printed airless tire with Local Motor’s Olli 2.0 autonomous shuttle. Airless tires (known as non-pneumatic tires, or NPTs) offer improved efficiency, lower replacement costs, and higher durability. This trial run is being tested in Jacksonville, Florida, allowing both companies to pilot their innovative technologies.

The Jacksonville Transportation Authority (JTA) began this project in October of 2020 in order to implement new autonomous and electric vehicles into their public transportation system. Using vehicles that are compatible with 3D components improves the repairability of the transportation fleet (as discussed in our prior article “3D Printing for Bus Transportation Critical Repair Parts”), which is a key focus for the JTA.

The Olli 2.0 itself is made of 80% 3D printed components, including the entire body, chassis, and various other parts. The Goodyear wheels, however, are unique as they are both 3D printed and airless, allowing Goodyear to test their wheels in a broader application and show consumers and companies that NPTs are feasibly capable of being the next standard in tires. NPTs operate much like springs, where instead of air distributing forces throughout the tire, a rubber lattice within the tire flexes to distribute the load of the vehicle, as well as shocks from the roadway. This makes the tires significantly more durable, while still being able to offer various types of treading for different situations (such as dirt, snow, and standard daily use). Including the tires, the Olli vehicle is easily repairable since most parts are 3D printed.

Michelin Uptis Tire [michelin.com]

Other companies have been developing and introducing NPTs and 3D printed tires of their own design, most of which employ 3D printing for their production. Michelin collaborated with General Motors to design and develop their Uptis (Unique Puncture-proof Tire System) tire, which is airless, puncture-resistant, as well as being 3D printed. Michelin found their 3D printing process led to a more sustainable and easier-to-produce tire that requires less material to construct, while still offering the same performance as traditional air-filled tires.

Additionally, like the Goodyear tire design, the Uptis tire is fully puncture-proof. Due to the design of the lattice, as well as the lack of air, a puncture in the tire will not impact the performance of the tire, as the lattice will still be able to react fully and effectively even after a puncture. This allows the tires to last significantly longer than traditional tires, reducing costs for their users.

Many large tire companies have begun to shift their focus on improving their distribution strategies and incorporate new and unique technologies into their processes, such as 3D printing. Recently, Convoy and Flexport, a digital freight network and a global logistics platform, announced a strategic partnership to improve Convoy’s freight automation and distribution, which Goodyear (among other tire companies) being a notable customer.

Activities like vehicle repair can be difficult for companies with such freight scales. 3D printed parts, such as NPTs, offer freight companies (and vehicle drivers themselves) huge benefits in reduced repair costs, as well as increased product lifetimes. Similarly, Goodyear Tire & Rubber Company and Cooper Tire & Rubber Company announced a merger agreement, joining together the two companies’ complementary product portfolios. With this merger, manufacturing and R&D will be shared, allowing the combined company to include new innovations and expand its scale. With this new focus on innovative products and technologies to push the merged company forward, 3D printing (and NPTs) will serve to be a vital part of the Goodyear portfolio.

The Research and Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Tire and automotive manufacturers continue to increase the use of more innovative technologies, including NPTs, into their product catalogs. 3D printing is a key aspect of this, as it allows companies to produce unique, cost-effective, and easily replaceable parts that could not have been produced previously, with NPTs being the most notable example. This innovation will continue to drive the industry forward, especially as the industry continues to adopt, integrate, and innovate with 3D printing technologies.