Raise3D announced a new line of professional 3D printers, the Pro3 series.

The new series is based on their successful prior series, the Pro2, but with a number of enhancements and improvements that will dramatically increase ease of operation.

The Pro2 series was notable in that it introduced a number of ease-of-use features, such as a filament-out sensor, dual toothed-wheel extruders, weight reduction, dual lifting toolheads, dual cooling fans, optical end stops, 32-bit controller, improved touchscreen and much more. Note that Raise3D is not discontinuing the Pro2 series, but instead places the Pro3D series as machines more suitable for frequent operations.

The Pro3 series includes all that and adds several more intriguing features. There are two models thus far:

- Pro3: build volume of 300 x 300 x 300 mm

- Pro3 Plus: build volume of 300 x 300 x 605 mm

Let’s take a look at the most interesting new features of these machines.

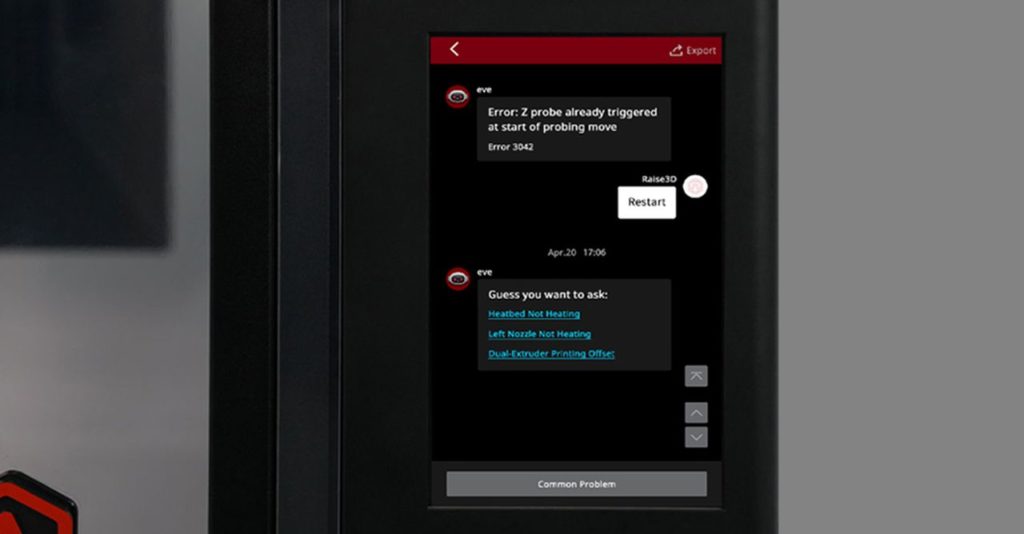

Raise3D “EVE”

The most interesting new feature is called “EVE”, and I’m sure you have no idea what that means. It’s actually the name of their new “smart assistant system”, a kind of wizard that appears on the touchscreen from time to time. Raise3D explains:

“The Pro3 Series has a built-in smart assistant system known as EVE. Similar to what is common practice in 2D printing, the EVE assistant can guide users to accurately locate and resolve issues that might affect the final print job. It also has a function that analyses printer usage and sends users reminders of scheduled interventions to ensure that printer maintenance is performed on time.”

I am aware of other 3D printers that have wizard-like systems used during initial set up, but none that do so during regular operations. This looks to be a ground-breaking move that might soon be copied by other makers of professional desktop 3D printers.

Swappable Hot Ends

The Pro3 series has the ability to very rapidly change toolheads. This allows easy switching of materials, from flexible to rigid to abrasive, or even increasing or decreasing the nozzle diameter. That makes the Pro3 ideal for those using many different material types.

One interesting aspect about the new “click and lock” swappable hot ends is that they are tracked. The Pro3 machine will be able to identify the toolhead and keep track of its usage. This means the machine could eventually recommend replacing the nozzle due to exceeding its useful life. This feature will be particularly useful if large quantities of abrasive material, such as carbon fiber-filled filament, are frequently used.

Air Flow Management

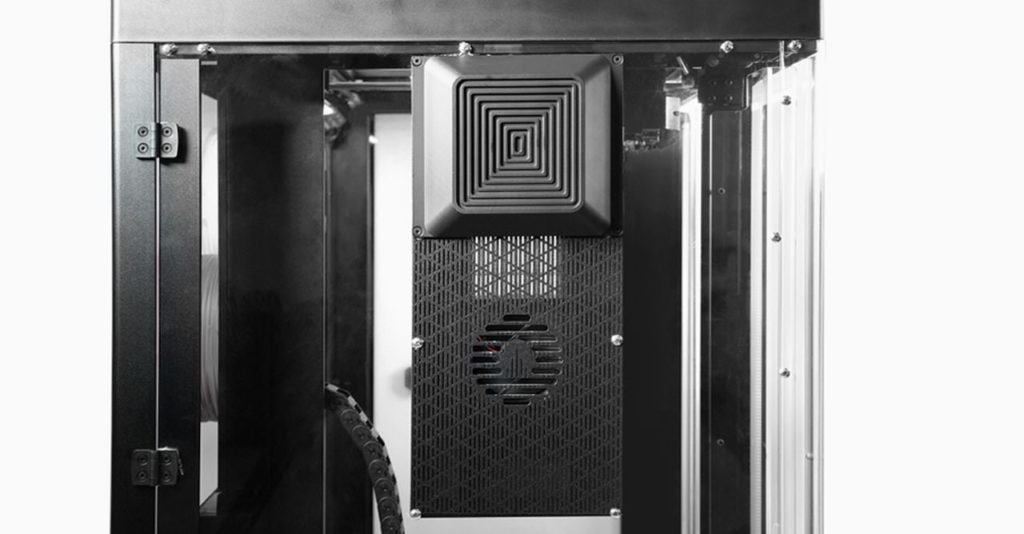

The Pro3 series includes a sophisticated air flow management system for its enclosed build chamber. The new system ensures the temperature of the interior is kept at a consistent level throughout each print job, as well as filtering air before it exits the machine.

This is quite different from many enclosed systems, which simply capture stray heat from heated print surface and hot ends, without managing the temperature. In such systems it is possible to have inconsistent print quality because the temperature in the build chamber varies during the job. Not so on the Pro3.

Other Raise3D Pro3 Features

Quite a number of other features are improved, ranging from the new HD-level on board webcam, to a revolutionary lightweight toolhead cable with digital thermal measurement.

The system now includes a spring-steel flexible print plate that makes print removal far easier. The company didn’t say, but it may be they offer different types of print plates in the future that are specialized by material.

One very interesting feature is a door sensor. When you open the door to the build chamber any in-progress 3D prints are automatically paused. I’ve seen door sensor features before, but usually on equipment operated by children. Typically the door is locked until the print completes, so that children don’t burn their fingers on the hot nozzle. But in the new Pro3 series there is a very different reason: print quality.

Recall that the Pro3 machines now maintain a consistent thermal environment by means of their new airflow system. This is to ensure print quality throughout the duration of the print job. But hold on, what if someone opened the door during a print? Would that not mess up the thermals on the inside? You bet they would; and that’s why the print is paused. Presumably when closed the printer does not resume until the build chamber again reaches the desired thermal state.

Pro3 Availability

Raise3D said the two new systems will ship late this year at a date to be determined, but they would be showing them to the public at major 3D print trade shows.

Pricing is as follows:

- Pro3: €4749 / US$5249

- Pro3 Plus: €6249 / US$7249

The new Pro3 series hits many points to simplify usage and should be well-received. I’m particularly interested to see how the new smart assistant “EVE” is seen by users.

Via Raise3D