Our review of the Anycubic Kobra Plus concludes with a look at software, print quality and final thoughts.

This is part three of a three part series, please read parts one and two.

Anycubic Kobra Plus Software

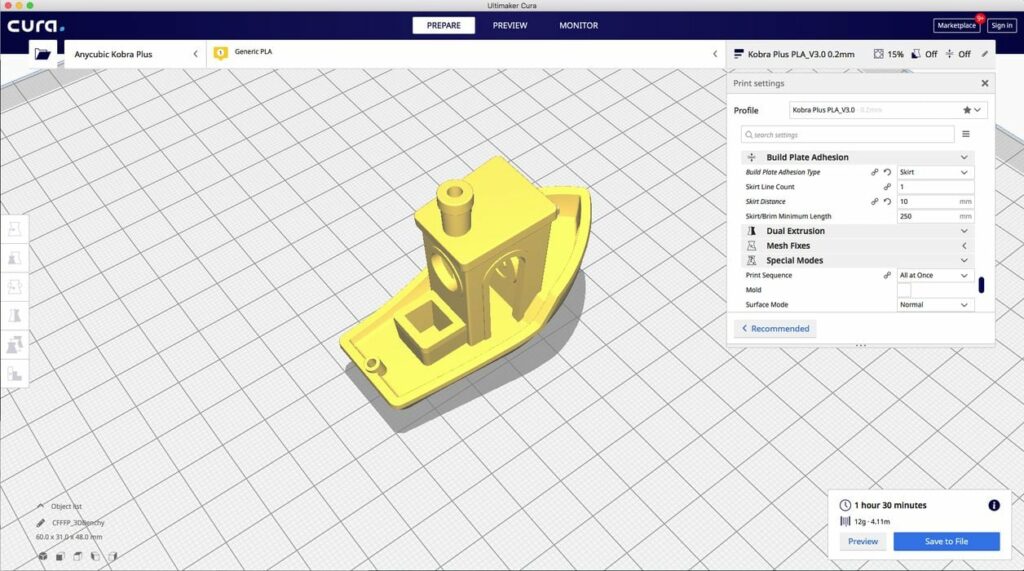

The Anycubic Kobra Plus uses a version of Ultimaker Cura provided on the USB stick. Those familiar with Ultimaker Cura will find this easy to use, although you might consider upgrading to the current version of Ultimaker Cura that might be more up to date than the supplied copy.

When we went to install Ultimaker Cura from the memory stick to slice our own files, using the supplied PLA profile, we found that the “Layer Height” slider was not adjustable when using Recommended Settings. When we clicked the small refresh arrow button located directly beside layer height, it made the layer height slider functional, but our custom PLA profile was no longer selected. We avoided doing that and did any layer height changes in the custom settings area.

It should be possible to prepare jobs for the Kobra Plus using other slicing software, such as PrusaSlicer, SuperSlicer or Simplify3D. However, you will have to manually recode the printer configuration and material profiles for those software tools.

We observed that Cura’s estimated print times were close to actual print times. Our Voronoi Tower print was estimated by Cura to be 9:49, when the actual print time was 10:14. We found smaller jobs had more accurate estimates and longer jobs tended to take a bit more time than estimated by Ultimaker Cura.

We used Anycubic’s manual instructions to successfully set up a custom printer on the Mac version of Ultimaker Cura and were able to slice jobs easily.

We found there were no material profiles provided for for PETG & ABS, and found only profiles for PLA & TPU, even though all four were apparently supported by the Kobra Plus. Anycubic should consider supplying material profiles for all materials said to be compatible in their documentation.

Anycubic Kobra Plus Print Results

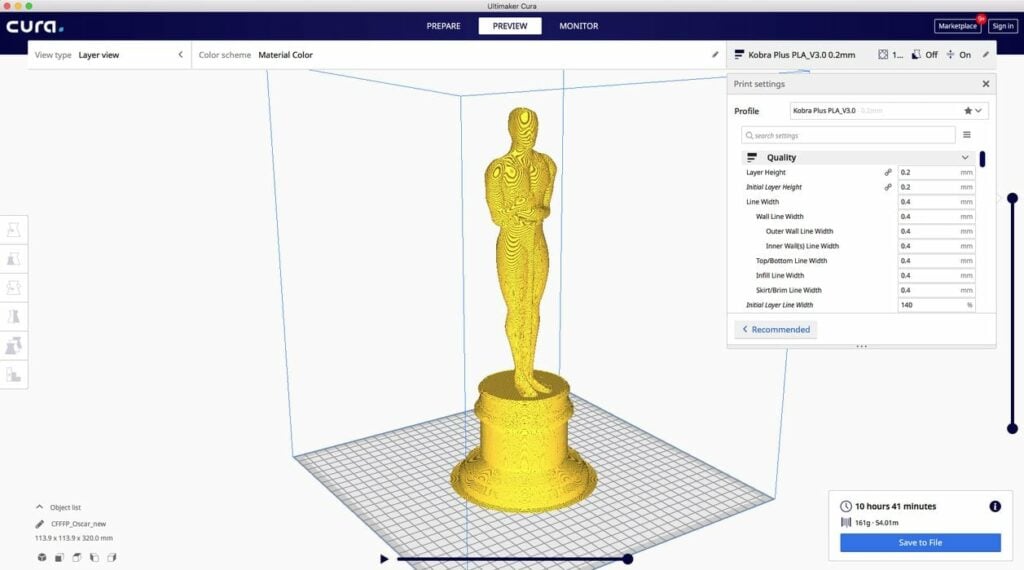

We ran our customary test prints using Anycubic’s Silk PLA+ Light Gold and found the printer to be extruding at decent speeds and delivering quality prints.

As for extrusion quality from the Bowden extruder, there were some small issues with surface quality on our Gyroid Vase print. We believe they could be remedied by tweaking the custom PLA profile retraction settings. In fact, while material profiles may be provided, specific spools can be somewhat chemically different, and thus it’s always a good idea to tweak settings when using new filament.

Our CTRL-V test print had some issues with bridging using the custom PLA profile, but that went away when we switched to a generic PLA profile.

Our Knurling Nut & Bolt test didn’t have the same “easy to spin” feel that we received from the direct drive extruder of the original Kobra, but the two still fit together well enough.

We decided to finish with some TPU tests. Flexible TPU material often doesn’t work well with Bowden setups, because it is like pushing al dente spaghetti through a tube, so we were quite very surprised when the Kobra Plus’ Bowden gears were able to grab the filament push it all the way down the filament tube and into the hotend!

Our first try at printing TPU was a fun little fork tong transformer which turned out much better than we had expected. The surface finish was smooth, with very consistent layers and no weak spots.

For our final print we did a zigzag bracelet which output flawlessly and was both strong and stretchy. We can say that the Kobra Plus 3D printer definitely handles TPU properly, even though it uses a Bowden extruder.

Anycubic Kobra Plus Final Thoughts

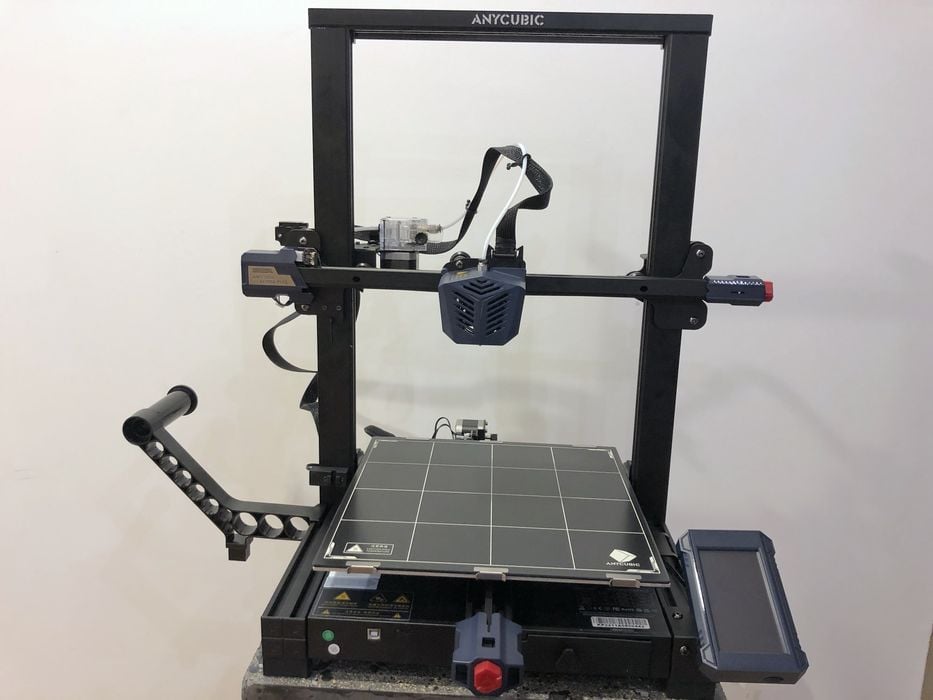

Much like its smaller sibling, the Kobra Plus was well boxed for shipping, to the point where it survived a hefty hit to the corner. It came with all the regular goodies, including a PLA sample to be able to start printing right away, and there was a convenient little drawer underneath the build plate, useful for storing all the car reader, tools & extra bits.

Instructions were terrific and assembly was a breeze, mostly because the connection points for the frame were milled right into the aluminum base, giving a perfect alignment of base to frame.

The new bed leveling system worked well and the prints really, really, really stuck to the glass bed, to the point where we had to use a Z-gap adjustment to decrease adhesion.

The Kobra Plus does not have WiFi, but the micro SD card was easily able to get GCODE files to the printer and a USB connection is available for those who want to direct connect.

The main feature of the Kobra Plus is a the ability to 3D print much larger objects in the massive build volume, far more than we are accustomed to. That is really the key selling point of this 3D printer. We were pleasantly surprised that TPU worked very well with the Bowden extruder, as it we’ve never seen this before.

Taking everything into consideration, we really like the Kobra Plus.

ANYCUBIC

KOBRA PLUS 3D PRINTER

★ BEGINNER 7/10

★ ENTHUSIAST 8/10

★ PRODUCTION 4/10

BEST FEATURES

✔︎ Large build volume

✔︎ Easy assembly

✔︎ Can print TPU

QUESTIONS

✖︎ Plate too sticky

✖︎ Missing profiles

✖︎ Side mounted spool

This is part three of a three part series, please read parts one and two.

Via Anycubic