Our look at the Kingroon KPL1 high speed 3D printer concludes with print results and final thoughts.

This is part three of a three-part series. We invite you to read parts one and two.

Kingroon KLP1 3D Printer Print Results

Our method of evaluating 3D printers often uses consistent 3D models for every review. This approach offers a comparative benchmark across different printers. While we’ve previously reduced the size of our prints to fit within our review timeframes, this review of the KLP1 saw us running everything at full size and maximum speed.

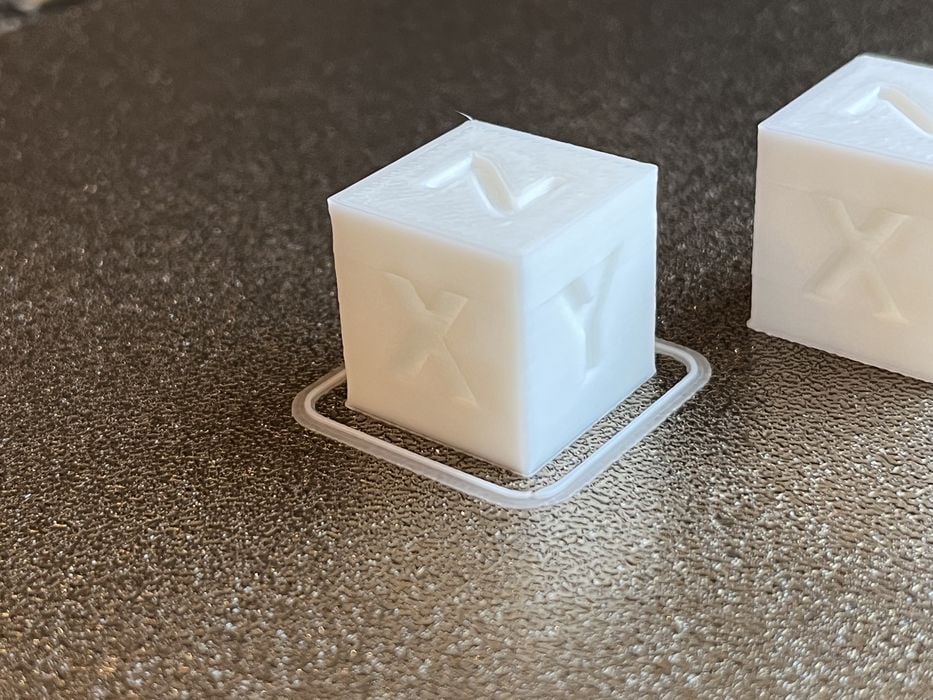

Specific models, like the 3D_test_V3 and Cube_V1, are intricately designed, making them ideal for identifying any printer shortcomings. The Kingroon KLP1 impressed us, handling both these challenging prints seamlessly at high speeds using the supplied HS-PLA filament.

However, our HS-PLA filament sample was soon exhausted after the first few test prints.

Transitioning to a standard PLA that wasn’t billed as “high speed”, we were skeptical but delighted to observe that the print quality remained the same, even at high speeds.

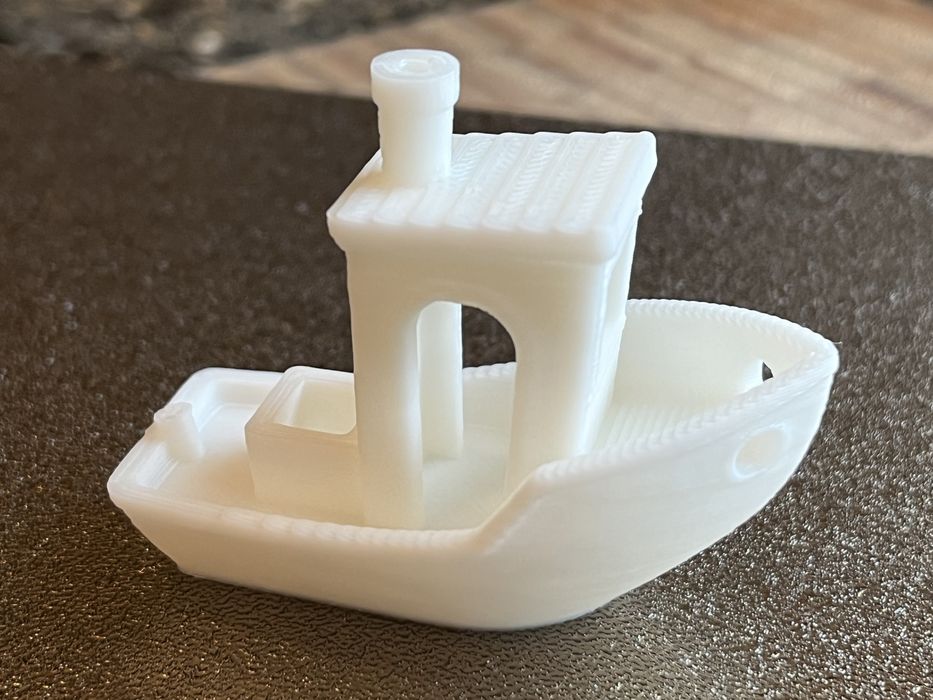

For instance, when we reprinted the 3DBenchy–fast.gcode, the output was almost on par with the HS-PLA filament quality.

Maintaining the same 350 mm/s PLA Cura profile, we tested out other models. The results, such as the Knurling Nut & Bolt and Cylindricity Test, were highly satisfactory.

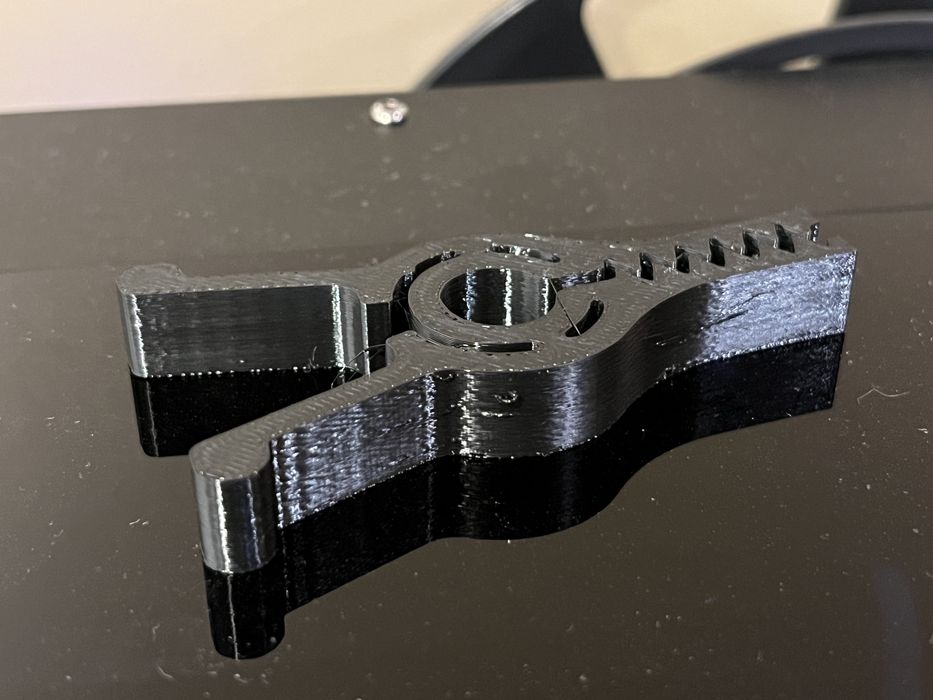

Intrigued by Kingroon’s recommendation, we gave OrcaSlicer a try, specifically with the Planetary Gears model. The estimated print time and the actual print time varied slightly. But, once the print was removed and the gears were adjusted, the mechanism functioned smoothly. To ensure thoroughness, we replicated the same model using Cura and found a slight improvement in print time and equally impressive quality.

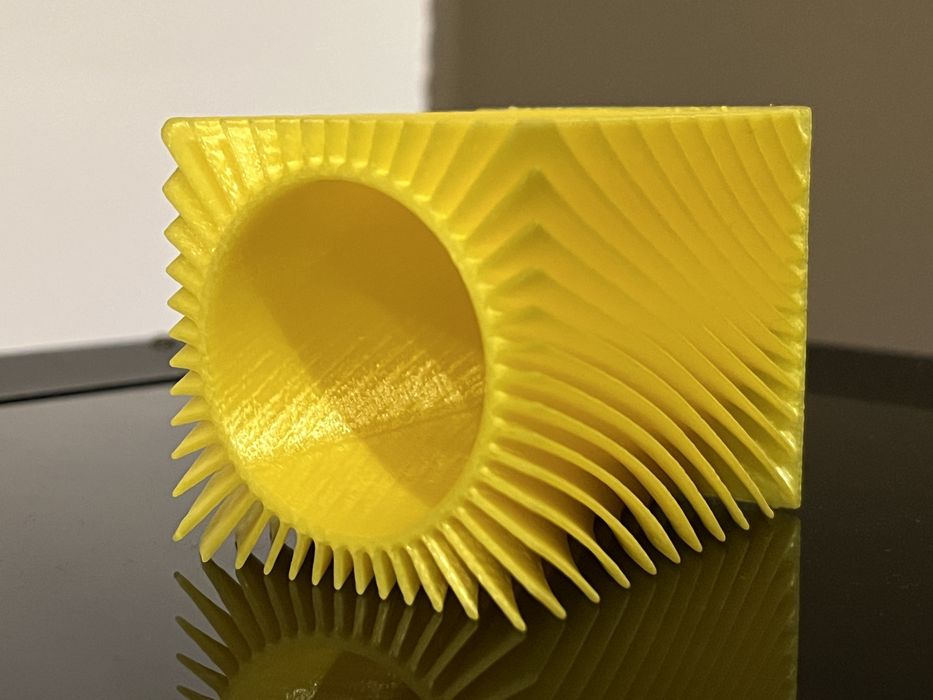

Our experiments continued with Cura paired with Kingroon’s signature yellow PLA. The results for the “spiralize outer contour” prints, such as the Spiral_Vase1 and Rib Vase, demonstrated very good detail.

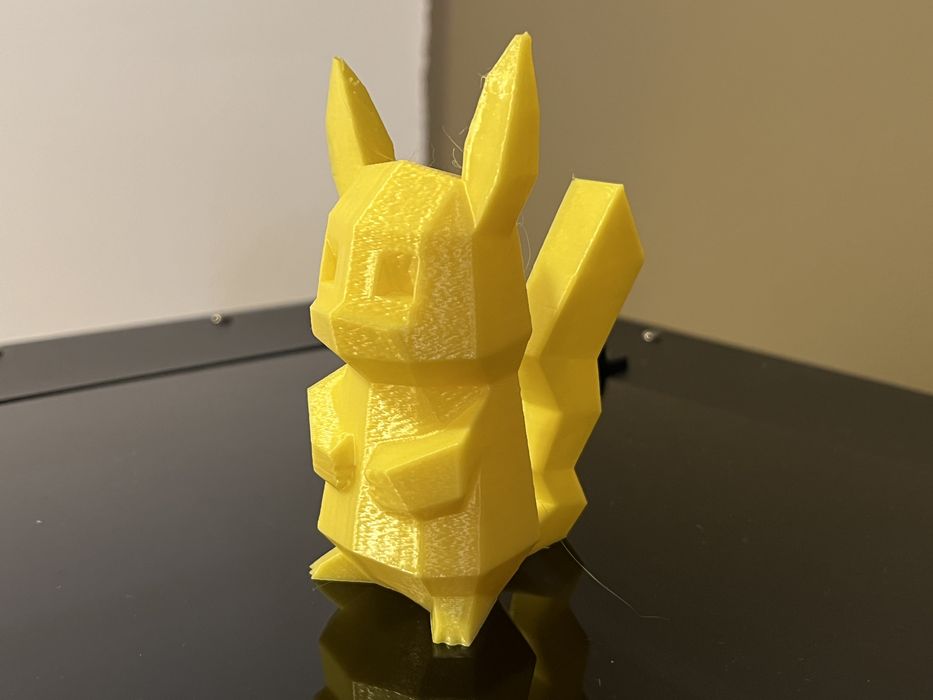

Additionally, models like the Low Poly Pikachu and Nervous System Lamp showcased both rapid print times and impeccable surface quality.

Although the KLP1 didn’t come with provided filament profiles for PETG, ABS, and TPU, we were curious to see its compatibility.

Our initial test with PETG using the given PLA profile was somewhat challenging, with issues like poor adhesion. Recognizing the need for optimization, we curated a tailored PETG profile using OrcaSlicer, adjusting speed, temperature, and other parameters. Our subsequent PETG and ABS prints, like the Chip Bag Clip and Bottle Opener Whistle, respectively, reflected marked improvement, challenging our previous print-time expectations.

Our experimentation with TPU began with a Grip model for a lightsaber build, printed at only 25mm/s as this material usually requires slow print speeds. The first run demonstrated remarkable print quality. However, removing the model from the build plate was quite a task.

Encouraged by the results, we increased the speed and tested a flexible Bracelet model. Despite the challenges typically posed by TPU, the output was achieved in a record time and was of superior quality.

Concluding our print tests, we returned to Cura and attempted the Torture Toaster model using Kingroon’s custom PLA profile. The model, barring a tiny glitch, was almost flawless.

Kingroon KLP1 3D Printer: Final Thoughts

Kingroon’s attention to packaging is quite evident. The intact arrival of the KLP1 underscores their experience ensuring product safety during transit. On opening the box, users are immediately greeted by the manual and assembly instructions thoughtfully placed at the top.

Assembly was a breeze, requiring only the addition of enclosure panels and setting up the spool holder. Although the printed manual was a useful inclusion, the digital version on the accompanying memory stick seemed slightly more current.

Connecting the printer to WiFi was a more intuitive process than anticipated, and the touchscreen ensured a seamless setup, even at distances beyond the suggested range.

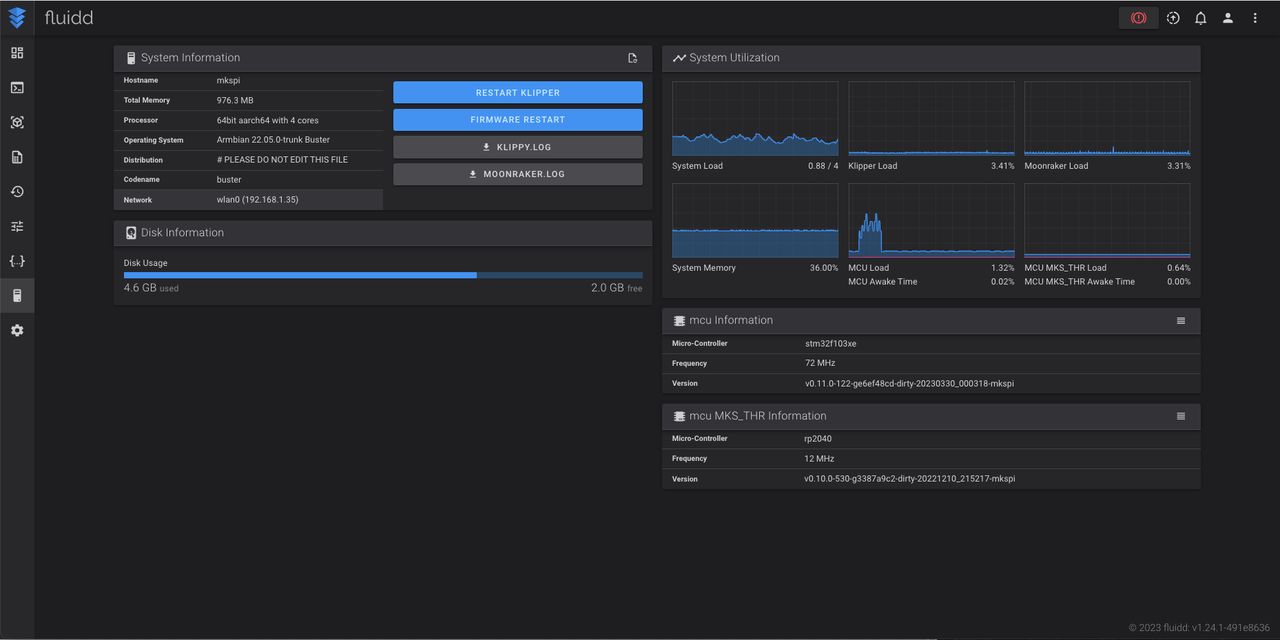

Navigating the Fluidd web interface proved to be refreshing, and quite unique for 3D printers without a set-top box. It offers a wealth of detailed data, standing in sharp contrast to the limited visuals of a typical printer’s LCD screen. That said, the touchscreen was also useful, especially for hands-on tasks like loading filament.

Kingroon’s nod to UltiMaker Cura in the manual seemed typical, but we were surprisingly directed to OrcaSlicer by Kingroon afterwards. Both slicing tools impressed, but the absence of varied filament profiles might pose challenges for newcomers. Still, our own homemade profiles for PETG, ABS, and TPU demonstrated the printer’s range and proved the versatility of the KLP1.

Apart from a minor glitch with the Torture Toaster model, the prints across different filaments were of consistent high quality and produced swiftly.

The KLP1, with its fine-tuned features and stalwart performance, undeniably raises the bar in its price bracket. Kingroon now seems to be a player in the burgeoning high-speed printer arena. Their latest 3D printer, the KLP1, is an visible demonstration of their innovation.

KINGROON

KPL1 HIGH SPEED 3D PRINTER

★ BEGINNER 6/10

★ ENTHUSIAST 9/10

★ PRODUCTION 8/10

BEST FEATURES

✔︎ Print quality

✔︎ Fluidd web control

✔︎ High speed firmware

QUESTIONS

✖︎ Manual discrepancies

✖︎ Missing profiles

✖︎ Fluidd timestamp issues

This is part three of a three-part series. We invite you to read parts one and two.