Charles R. Goulding and Preeti Sulibhavi sit down with Arjun Chandar, founder and CEO of IndustrialML, to discuss his ventures in technology and research.

Arjun Chandar has a Master of Engineering from the Massachusetts Institute of Technology (MIT) and a Bachelor of Science from the California Institute of Technology (Caltech). Arjun’s expertise in Industry 4.0, robotics, sensors and other automated solutions is extensive. We recently had the opportunity to have a wide-ranging discussion with him.

His company, IndustrialML, focuses on providing real-time data integration and communication tools to help manufacturers increase their operations throughput and reduce their expenses. IndustrialML recognizes that today’s workforce is more transient than ever. To assist manufacturers in dealing with modern workforce challenges, the IML software platform collects and curates sensor, IT, video, and audio data; turns the data into critical information using statistical and artificial intelligence tools; and most importantly, sends real-time notifications and instructions to various stakeholders across the business whenever critical events happen.

For example, instructions for a production line in a factory can be freshly sent when the product being made changes over, or when temperature or power settings for equipment are trending in the wrong direction, or when algorithms predict a high probability of product error. Instructions are tailored for different roles and disseminated simultaneously, and they can remain open until resolved, so employees can pick up where their counterparts left off during a shift change.

IML’s notification and instruction system in particular makes workforce training more accessible for new employees and helps companies expand real-time workforce knowledge transfer, which provides more job flexibility and job satisfaction for employees and allows the manufacturers themselves to withstand turnover without operations missing a beat.

Arjun agrees that there are other alternatives to addressing the challenges of a more transient workforce. Some companies may choose hardline automation or basic workforce education, but Arjun believes that these measures are supplemental and not stand-alone solutions to the current workforce paradigm. According to Arjun, “In building the workforce of the future, we must account for the reality now.” IndustrialML is just exiting its incubation phase and currently has a few select clients, including Daiwa Steel Tube Industries in Japan and Daiwa Lance International in Vietnam, to whom they are providing their software and services.

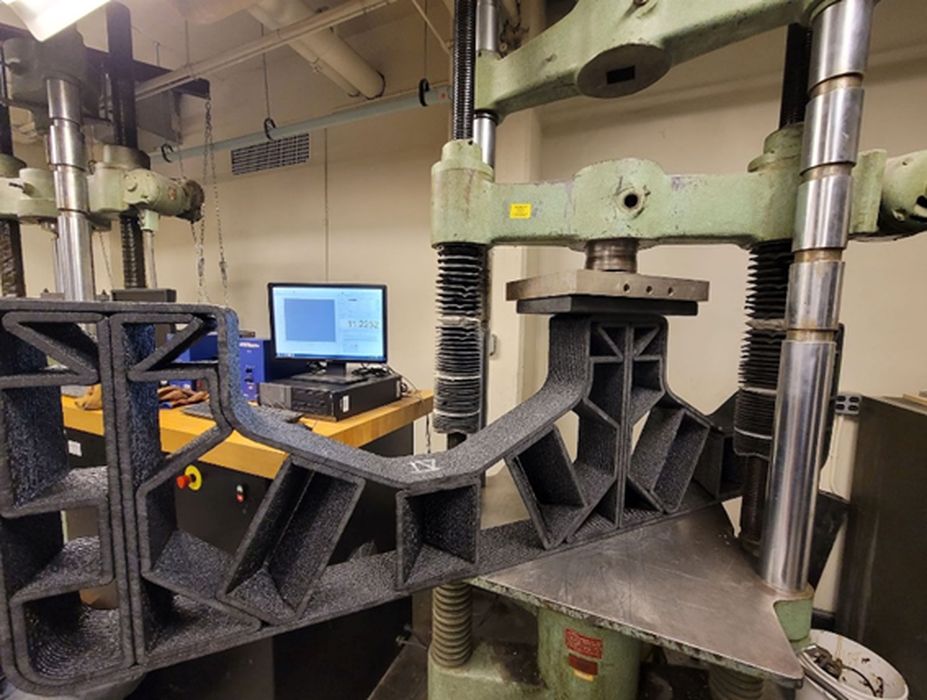

In addition to his corporate venture, Arjun Chandar is a Ph.D. candidate at MIT and serves as the senior graduate lead for MIT HAUS, a project aimed at providing quality, affordable housing for all. The group is working on building 3D printed houses for homeless and under-housed populations around the globe, using recycled polymer material such as plastic water bottles which can be sourced locally from anywhere.

MIT HAUS began as the brainchild of Dr. AJ Perez about four years ago while completing his thesis at MIT. Professor David Hardt serves as the project’s principal investigator and Dr. Perez as the group’s co-leader, with nearly 20 students assisting in the group.

Of the major subsystems for a building (lighting/electrical, HVAC/mechanical, and the building envelope), MIT HAUS’s research encompasses all parts of making the building envelope. The group has active research in process regarding the prefabrication of modules (i.e., walls, stairs, floors, roofs, foundations, etc.) and the recovery and extrusion of building materials (i.e., concrete assisted by efficient 3D printed thermoplastic designs for higher-end, commercial projects; or recycled plastics for more economical, residential projects). The key to the success of ventures driven by MIT HAUS’ work lies in flexibility, or modularity, wherein they can focus on the entire house or just specific sections of the building for certain projects in certain regions.

According to Arjun, often the balance between technology and policy can limit geographic selection for setting up commercial operations stemming from this research. In fact, much of the group’s prior ethnographic studies have come overseas, partly because of US regulatory and permitting issues and partly due to the vast homeless and under-housed populations across various regions of the world.

We are just scratching the surface of the homeless and under-housed population issue, so this work, Arjun believes, is still nascent. It will take years still to get this technology working at scale, but the group has grown quickly and will make substantial contributions to knowledge on the topic for years to come.

We also asked Arjun about how artificial intelligence (AI) impacts his work. In his corporate work, Arjun finds that AI is not a final solution for his projects, but rather, it helps supplement certain tasks and infrastructure challenges, including real-time knowledge transfer. For instance, in IML’s computer vision work, capturing live, streaming video can help in noticing certain defects.

AI can be programmed to alert operators when the probability of a product defect based on the video feed is sufficiently high. Then solutions can be prompted instantaneously. Or, AI can assist in compiling feedback from employees who are receiving real-time work instructions; language models can analyze and categorize the employee feedback based on what actions they took to resolve issues and integrate improvements into updated versions of the instructions for future alerts.

On the research side, Arjun believes AI can disseminate vast amounts of knowledge to a multitude of factories located around the world in real time to integrate improvements quicker. For example, if an employee in a 3D printing microfactory in one region discovers an optimal print setting for a particular material, then he or she can upload that setting and enterprise-level AI algorithms can incorporate that into global recommended settings for other teams around the world.

In general, AI can be an enhancement for humans as assistive technology and can replace more repeatable tasks, but it will not be an outright replacement for the intuition of humans any time soon. There will always be a need for human thought, human input and decision-making in real time, and Arjun’s priority for the use of AI is to enhance the quality of human work.

Arjun and his team are building and seeking partnerships with construction firms and materials companies that are interested in pursuing an innovative, economical and more sustainable way of building affordable homes around the world.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.