Charles R. Goulding and Arianna Coger discuss various ways in which companies and organizations are providing opportunities for a current and future workforce to foster and fine-tune their 3D printing skillset.

On July 14th, 2021, we enjoyed attending the Additive Manufacturing Coalition’s event discussing ways to develop workforces proficient in 3D printing. With all the benefits of 3D printing, it’s somewhat surprising that the technology is not widely taught to students and workers entering fields that could benefit from it. The opening remarks, presented by Congresswoman Mikie Sherrill, summarized many of the widespread advantages of additive manufacturing and the importance of education to expand its usage. Although the popularity of 3D printing continues to grow, we currently lack sufficient infrastructure to help teach workers how to effectively utilize the technology. The main purpose of this event was to explain the various ways companies and organizations have been helping students and workers expand their skillset with 3D printing training.

Ford’s Integration of 3D Printing

Dr. Ellen Lee, the Technical Leader of Additive Manufacturing for Research & Advanced Engineering at Ford Motor Company, discussed the various ways Ford had utilized 3D printing within its development and manufacturing processes. The company has several partnerships with 3D printing companies to help integrate the technology within their workflows. 3D printing has allowed them to stay flexible and quickly respond to market needs. We have previously discussed Ford’s rapid response to COVID-19, enabled by 3D printing, allowed them to accelerate the production of ventilators, respirators, and face masks. Ford currently uses 3D printing to easily prototype parts with optimized designs that would have been too difficult or costly to manufacture in the past. Dr. Lee emphasized the importance of providing specialized training to management, engineers, and operators on additive manufacturing to ensure the technology can be utilized to its fullest potential.

Somerset Community College’s 3D Printing Programs

The Kentucky-based Somerset Community College has developed additive manufacturing certification programs to help build the additive manufacturing skillset of their students. Many of these efforts have been led or influenced by Associate Professor Eric Wooldridge, who directs their Additive Manufacturing/3D Printing program. Kentucky has great involvement in the automobile and aerospace industries, where 3D printing is commonly used. Somerset Community College was the first institution in Kentucky to offer a certification program for 3D, with hopes that they would help build industry leaders.

At the Additive Manufacturing Coalition’s event, Professor Wooldridge discussed the impact of COVID and how the pandemic has exposed the fragility of supply chains in the United States. Like Ford, Somerset Community College began producing PPE to meet supply demands and help medical professionals safely treat others. If more companies and organizations were familiar with 3D printing, millions of face shields along with other equipment could have been quickly manufacturing early during the pandemic, reducing the severity of the shortages that had occurred. Somerset’s training programs have helped teach thousands of students the basics of 3D printing.

Case Western’s Think[box] Bringing Ideas to Life

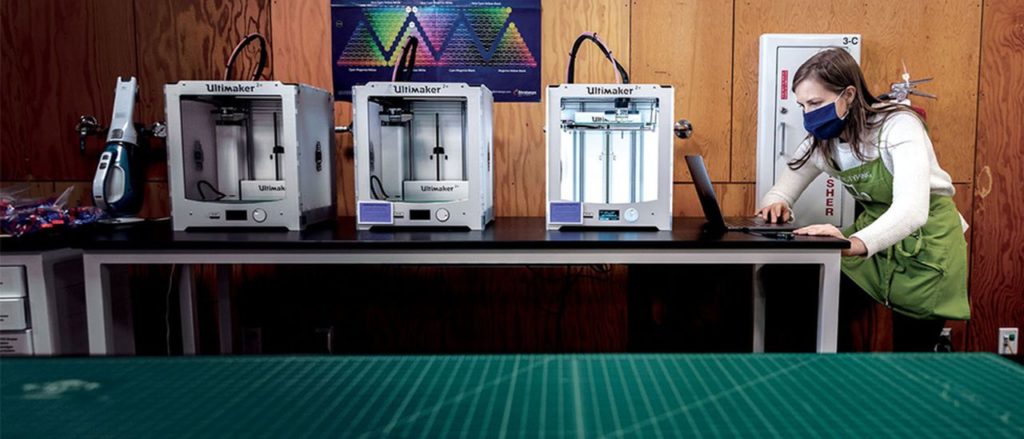

The third panelist, Dr. Jim McGuffin-Cawley, discussed the ways in which Case Western Reserve University (CWRU) has continuously worked on advancing 3D printing technology. The university has encouraged its faculty, students, and neighboring community members to engage in 3D printing activities using their facility known as the Sears think[box]. Think[box] is a seven-story building dedicated to bringing ideas to life with 3D printing and other technologies. The facility provides resources and training to transform prototypes into commercial products.

Several startups have launched due to the think[box] facilities including 3D Music, a company that is using 3D printing to manufacture acoustically accurate violins at a low cost. The two students who founded 3D Music began their prototyping process using the resources found at CWRU. It is likely that more great ideas and products will continue to come from CWRU as a result of their extensive resources and training for 3D printing.

The U.S. Naval Academy’s Usage of 3D Printing

The final panelist at the event, Captain Brad Baker, discussed how the United States Naval Academy (USNA) teaches their future Navy and Marine personnel the intricacies of additive manufacturing. The U.S. Navy’s “Print the Fleet” Program has been ongoing for several years now, with many submarine, drone, and ship parts constructed through 3D printing processes. Captain Baker directs the Maker Space at USNA, where students have free access to 3D printers and can complete project-based courses to gain a thorough understanding of the technology. The U.S. military strives to ensure its members stay educated on the latest technology to develop unique and advanced solutions. They help accomplish this task by emphasizing the importance of additive manufacturing within their school programs.

Companies taking on similar endeavors may be eligible for Research and Development Tax Credits.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software. As of 2016, eligible startup businesses can use the R&D Tax Credit against $250,000 per year in payroll taxes.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Each of the panelists at the event agreed that open-mindedness and a willingness to try new things are necessary to effectively utilize 3D printing. 3D printing has the potential to revolutionize the manufacturing industry and accelerate the development of new technology. To successfully achieve these goals, it is essential that workforces are provided greater opportunities to learn about 3D printing.