Juggerbot 3D is a lot bigger than I had realized, or at least their products certainly are.

The last time I had a chat with Juggerbot 3D was five years ago in 2017, when the then-startup, formed in 2014, displayed a professional desktop 3D printer, the ME12C.

At the time it was an interesting device because it ran slicing software directly inside the machine.

Today, things are a bit different at the Ohio-based company. They’re focusing directly on the industrial production market, and have a slate of products to match.

Their product catalog includes not only desktop 3D printers, but also large format machines, tools, print services, application development and materials.

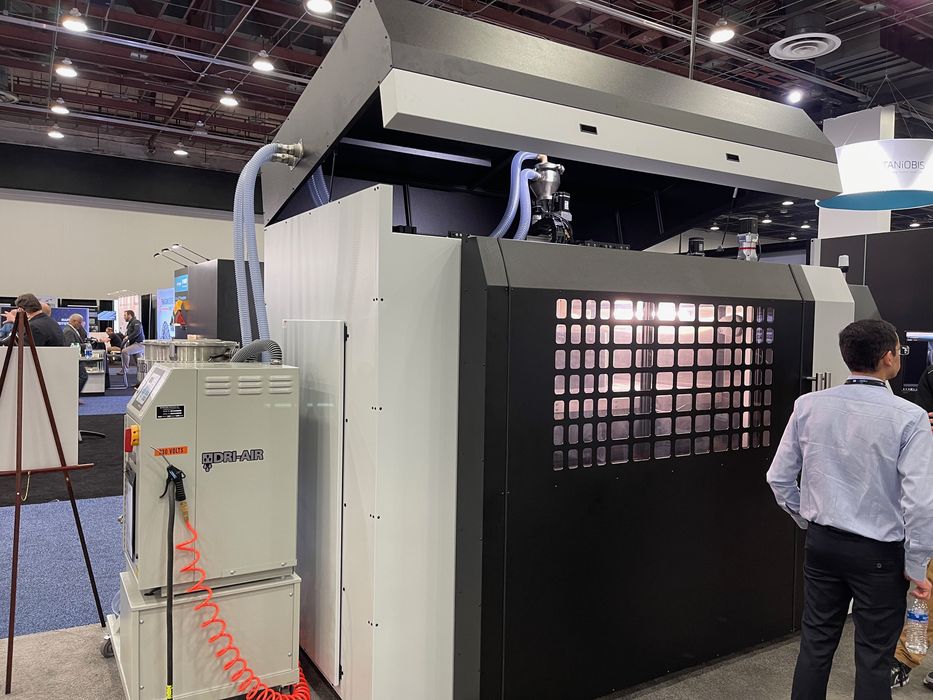

Juggerbot 3D’s flagship device is the truly massive Tradesman P3-44, which was announced in 2020. This enormous machine, seen at top, has a build volume of 915 x 1220 x 1220 mm, large enough for any reasonable 3D print, including huge mechanical prototypes.

The P3-44 has a build plate temperature of 120C, with a chamber temperature of 95C. The hot end of the P3-44 can hit 400C, enabling the use of many engineering materials.

The P3-44 includes a drying chamber that can be set as high as 200C, which will certainly remove the moisture from any material. This will increase print quality and reliability of the up to 68kg that can be stored in the dryer.

The layer height on the P3-44 ranges from as low as 0.375mm to a large 2.25mm. This may not seem as fine as seen in other 3D printers, but remember we’re printing meter-sized objects here where fine details are less important.

Here you can see an example of a print made with this technology. On the left is the raw print, while the right side shows a CNC milled surface that can be made quite smooth. In other words, the coarseness required for quick 3D printing can be eliminated with some post processing.

One of Juggerbot 3D’s clients was able to 3D print this entire truck fender using the system. While is probably isn’t the best way to produce volumes of parts, it’s quite speedy to produce large prototypes such as this item.

The P3-44 is a pellet machine, meaning it does not require the use of expensive filament. Instead it can directly use standard industrial pellets that can be sourced at much lower pricing.

Like filament, pellets must also be dried in order to obtain good print results. Here you can see a dryer attachment for the P3-44 that dries pellets before they are scooped up into the hopper at the top of the machine, shown here:

Juggerbot indicates the P3-44 can 3D print up to up to 13.6kg per hour, and that’s a huge amount of material. Consider how long it takes to 3D print a single 1kg spool of filament on a desktop device and then multiply that by 13.6. The P3-44 can do that in one hour.

The P3-44 is set up for use in production facilities, with multiple safety features, network connectivity and remote control systems.

The P3-44 is not an inexpensive device, as it’s retail price is something close to US$230K. However, we are told it has been quite popular with mold makers. They would use the system to produce large-sized molds for parts, as well as large-sized production tools.

Large format 3D printing is a niche, but it is quite a profitable one as manufacturers gradually discover the benefits of additive manufacturing. Large components, prototypes, tools can be produced far faster and often at lower prices.

It seems that Juggerbot 3D is in the right place at the right time.

Via Juggerbot 3D