Charles R. Goulding and Preeti Sulibhavi look at how Lippert Components is using 3D printing.

It’s no surprise at this point that we are experiencing a global supply chain disruption crisis. Instead of playing victim to the crisis, Lippert Components, Inc. (LCI) decided to do some research into how 3D printing and additive manufacturing could fill the gap. What they found is very useful and highly pertinent to the industry.

Lippert Components, Inc.

Lippert is a global leader in the manufacturing and supply of highly engineered products and customized solutions that are dedicated to re-shaping and growing the Recreational Vehicle (RV), marine, automotive, commercial vehicle and building components industries. The building products part of Lippert’s business includes electronics, furniture, glass, metal, power and motion systems, and plastics. By combining strategic manufacturing resources with the power of technology, Lippert is creating a legacy of innovation.

In 2017, Lippert released a study that indicated utilizing 3D printing could revolutionize the entire metal casting industry. Their research focused on the feasibility of integrating binder jet additive manufacturing technology, compared to more traditional methods.

Lippert and 3D Printing

The study revealed that 3D printing, in conjunction with sand foundries, could be beneficial “with future work integrating this technology into foundries and making it more affordable.” LCI Business Systems Analyst, Chitralekha Beniwal, collaborated with Paul Lynch of Penn State University and Joseph Wilck of the College of William & Mary on the research study that was unveiled at the Institute of Industrial and Systems Engineering conference.

Lippert has various subsidiaries in various industries.One of its focuses is on plastic molding. We have previously written on Fabbaloo about how 3D printing impacts the plastics industry.

In a recent Barron’s article, Lippert was featured as a company that has taken measures to shift its focus from selling parts to RV and boat manufacturers to the now more profitable aftermarket business (or selling replacement parts and components). Decreased material costs and the continued expansion of aftermarket business indicates that LCI’s sales and revenue could grow faster than is currently predicted.

The aftermarket business is a great place to introduce 3D printed components. 3D printed parts are lightweight, highly durable and fabricated quickly.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

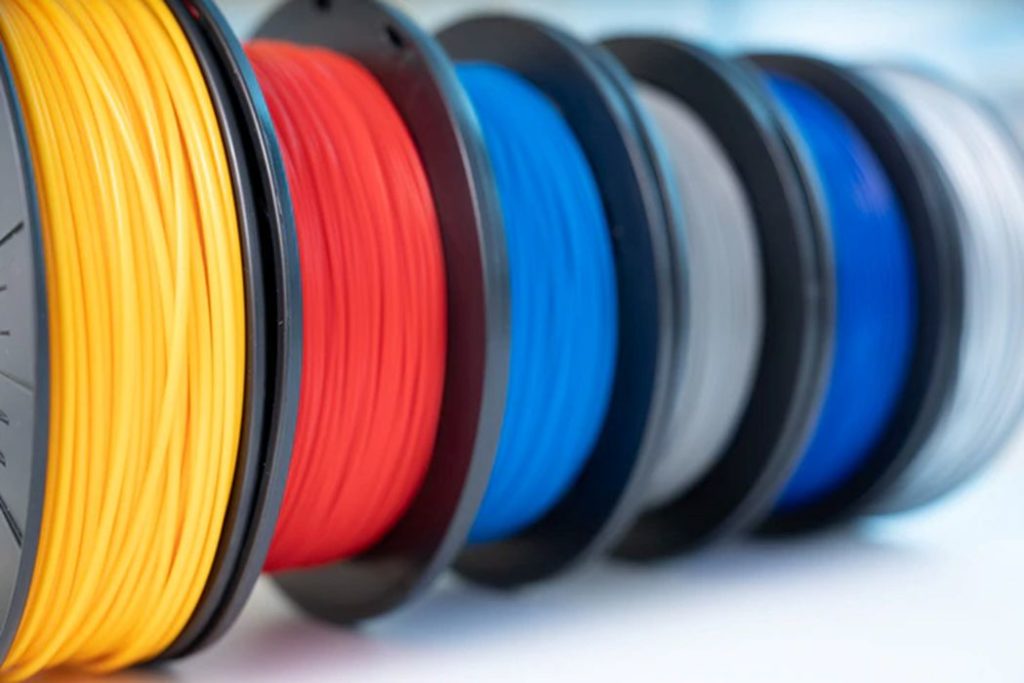

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

With companies hurting from supply chain shortages and disruptions, it seems apparent that 3D printing can provide real-time, cost-effective solutions. Particularly, if in the aftermarket parts business.