What’s up with MX3D? We had a chat with them.

MX3D is a Netherlands-based company that’s developing a WAAM (wire arc additive manufacturing) system. Basically, it’s a robotic arm with a wire extruder at the end, combined with a powerful electric arc that can instantly melt the wire. By moving the toolhead around in 3D space it’s possible to build large 3D metal objects.

The company previously performed a series of demonstrations, including a 3D printed bridge in Amsterdam, a prototype for a lunar base, and prototypes for repairing oil & gas pipe repair, among other ventures.

Two years ago the company raised a notable €2.25M (US$2.4M) for launching their robotic 3D printing system.

In discussions with an MX3D representative, we learned that they’ve made the move from “early development” to the “production phase”.

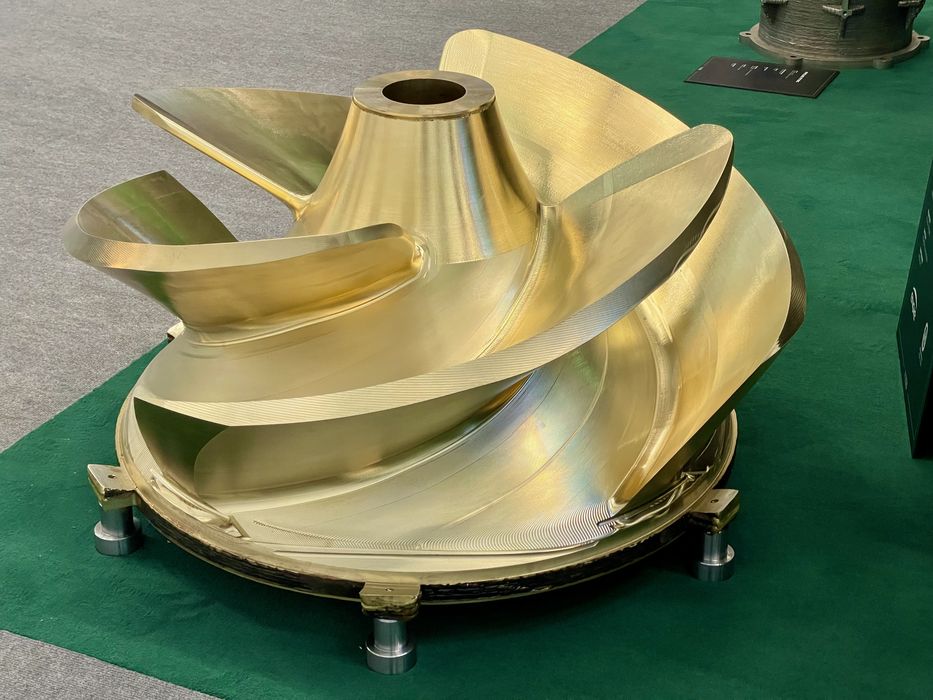

One of the biggest steps they undertook was to work with an unnamed energy company to produce a large impeller, shown at top. The most important part of the project was to establish a feasible qualification process for their unique 3D printing method. This apparently was achieved, and it “looks like welding standards”, which is actually not surprising given the similarity in process.

MX3D has spent effort to simplify the use of their equipment for customers, making it “not overwhelming”, as is often seen with other equipment that requires vendor staff to assist. The system is able to use collected data from itself to automatically resolve certain types of problems, and notify operators if unsuccessful.

MX3D said it’s possible for customers to start work with the equipment “in a day or two”, thanks to an educational course they provide.

What really impressed me was the impeller print above, which apparently took nine days to complete. Take a close look at the detail above, and then compare it with a sample bicycle frame print from MX3D from a few years ago. Quite the difference — evidently MX3D has been quite busy.

As for the company itself, they’ve now grown to 30 staff, and apparently are gathering “good revenue”.

It seems that MX3D is doing quite well.

Via MX3D