NASA has a new project to 3D print regolith.

The Redwire Regolith Print project is hoping to prove the feasibility of 3D printing regolith, the name for soil found on other planets and moons. It’s called regolith instead of “soil” because there’s no organic material present. It’s just sand, rock and particles of the local materials.

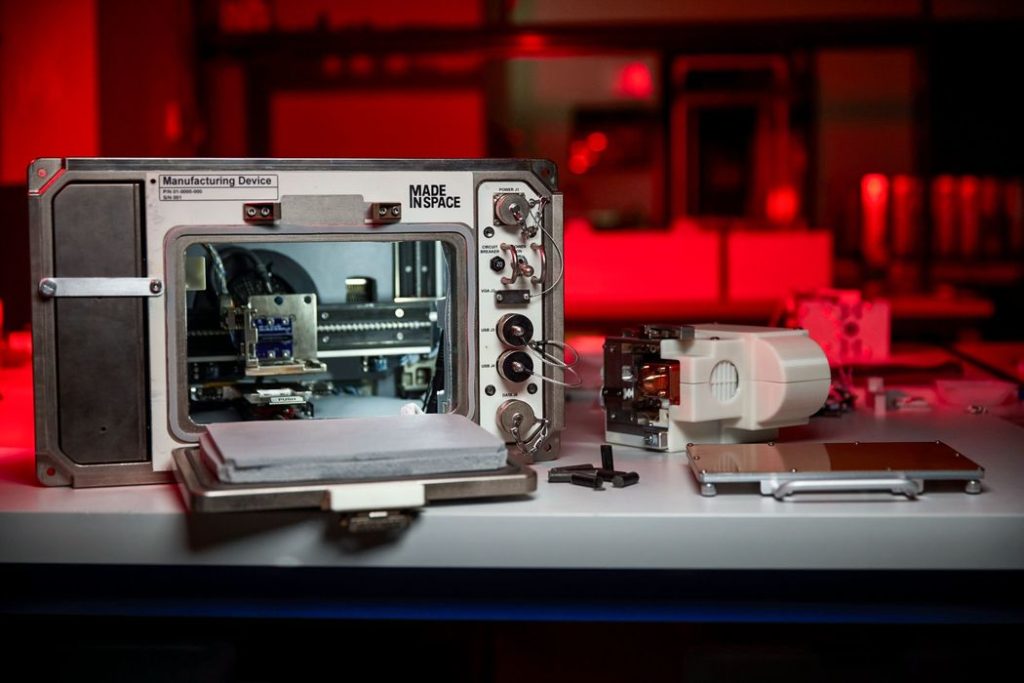

By the way, “Redwire” is the name of the investment company that acquired Made In Space last year. Made In Space has long been active in the space industry, having flown multiple additive experiments to the International Space Station. They currently operate a 3D printer on board, named the Made In Space Manufacturing Device.

Why 3D print regolith? There’s a straightforward answer here: it’s much cheaper to use local materials for building than shipping them a long distance. In this case, the “long distance” is literally the distance between the Earth and Moon: expensive!

The situation is analogous to early Arctic explorers, who initially sought to bring all the required supplies with them. Generally, they died or failed in spectacular ways. Meanwhile, the local Inuit folk prospered by using local materials: eating local animals and building structures from rocks or even snow (igloos). Once the explorers adopted these practices, their Arctic expeditions began to succeed.

This, I believe, is what NASA is thinking: 3D print structures on the Moon using local materials and the only shipment required is the 3D printer, and perhaps some other consumables.

But before they can do that, they must prove that the system works. That’s where the Redwire Regolith Print project focuses. NASA explains:

“The Redwire Regolith Print (RRP) demonstrates 3D printing with regolith feedstock material in microgravity using the Made In Space Manufacturing Device currently aboard the International Space Station. This demonstration could help determine the feasibility of using resources available on planetary bodies as the raw materials for on-demand construction of housing and other structures. This capability reduces the amount of materials needed on future exploration missions, thus reducing launch mass.”

It seems that the approach here is to send up “extruders and beds” that will be installed on the existing ManD 3D printer on the ISS. Test prints will be triggered by astronauts, and the resulting prints will be returned to Earth for detailed examination. At the same time, the ManD modifications will be de-installed and also returned.

NASA explains the test program:

“The standard test methods selected for analyzing the printed material are ASTM D695-15 for compressive strength, ASTM D638-14 for tentile strength, and ASTM D790-17 for flexural strength. Three samples are printed on orbit, one each for extracting the corresponding specimens of the ASTM tests. These test standards are used for this mission due to their applicability to the test material, the geometry of their required specimens, and their minimum required sample sizes. The standards chosen allow for a full specimen set to be extracted from a single print. The purpose of the selection criteria is to obtain all specimens for a particular test standard from the same source material sample.”

NASA describes the material as “regolith-laden simulant material”, but it’s not clear what specific material will be used. However, lunar regolith’s composition is well understood due to Apollo samples from the 1970’s.

Should this experiment succeed, it is likely a follow up mission would be eventually undertaken to place a similar 3D printer on the lunar surface after humans return in or after 2024. The device could be used to 3D print small experimental structures using actual regolith.

Meanwhile, I will follow the progress of this project when it is eventually launched to the ISS.

Via NASA