NPPower revealed their new small-format metal 3D printer, the Malachite.

You may not have heard of NPPower, and that’s completely understandable. The Slovenia-based company was formed only in 2020 and only last week revealed their product to the world.

The company was formed by individuals having seven years experience in the 3D print industry, mostly involving metal printing for the dental industry. Their experience in that environment revealed deficiencies in the market, and NPPower sought to rectify them with the Malachite 3D printer.

Their goals for this device are straightforward and surely will resonate with many clients: they wanted to build a machine that’s small, fast, affordable and versatile. It appears they’ve done so.

The machine is indeed small, as you can see in the top image. It sports a cylindrical build volume of 125mm diameter and 100mm height, which should be sufficient to build small metal objects. That clearly includes dental appliances, by coincidence.

The machine is versatile, as it can handle “all non-reactive metals”. Currently they are printing with cobalt chromium, stainless steel, bronze and more, but intend on developing new materials alongside clients. It’s also possible to 3D print precious metals in the Malachite, or privately developed alloys not on the market. NPPower representatives hinted that next year they may be able to get into reactive metals.

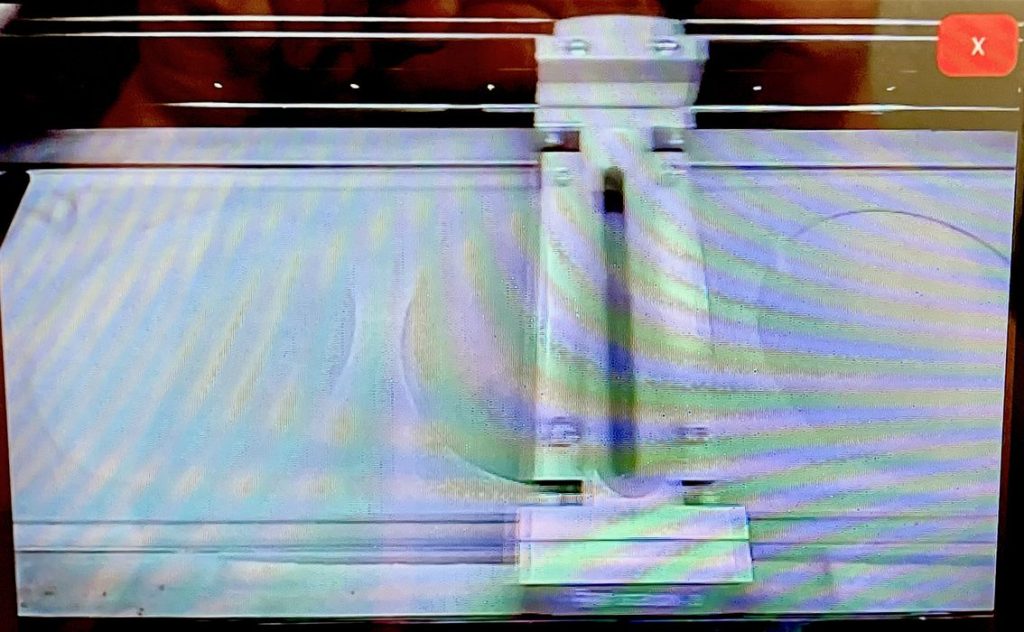

As for speed, the Malachite achieves faster print rates due to a dual recoating system. In this screenshot from the build chamber monitoring camera, you can see the build volume in the center, with two powder reservoirs on each side. This enables the Malachite to sweep across in both directions to recoat new layers with fresh powder. Single recoaters would have to move back and forth to reposition for the next layer, but that’s not required in the Malachite.

One of the interesting features of the Malachite is that it has quite low gas consumption. This is due to a sophisticated air circulation in the design that also helps maintain even temperatures.

Another curious feature is a “360 LED Status Bar”. This is visible as the green band around the top of the machine. Basically the LED lights can convey the current status of the machine via different colors, and it is clearly visible from any direction. That could be useful in a crowded lab.

NPPower is also able to provide the Malachite with different custom case colors if requested. Personally, I’d go with the black and green.

The price of the Malachite is perhaps its most intriguing feature: the entire system starts at only €75,000 (US$78,000). This includes “no hidden fees or Subscriptions” and “free software updates”.

That’s an outstanding price for a higher-speed metal 3D printer.

Who is this device for? According to NPPower, they see the Malachite being used by jewelers, educators, labs for experimentation. The latter is perhaps the most interesting case, because the low build volume allows for smaller batches of experimental alloy powders, which should lower experimental costs. The high speed printing will also enable more prints to take place in a given time period.

One interesting application explained to us by NPPower was the reproduction of cultural artifacts. Evidently the machine’s ability to 3D print bronze attracted some researchers who had 3D scanned ancient metal objects. With the Malachite, they were able to reproduce these bronze objects — in bronze.

The Malachite seems to be worth consideration for certain applications seeking to quickly produce small metal objects.

Via NPPower