Charles R. Goulding and Preeti Sulibhavi explain how their clients have tackled manufacturing automation.

Many of our clients, although dealing with pandemic-related labor shortages, are seeing growth opportunities and are automating their manufacturing and distribution processes to meet both needs. Analyzing many of these projects, we have put together a 10-step plan.

- Assemble the appropriate team of senior management, engineers, plant technicians, finance and marketing professionals and outside consultants to create and implement the project. This is the time to gather research and construct a general plan or strategy of how the project will be executed.

- Identify your customer addressable market while also serving your existing customers and expanding your market. Who are your target customers and what do they need? How can your company provide these items and what is the best way to do so? It’s always good to gain some insight from your end-users, whether it is product feedback, transaction surveys, focus groups, or general correspondence. Know your audience, as they say.

- Take a look at what leading competitors and best-of-breed companies are doing. Visit and ask questions. There is always room to grow and learning from the best can only help in this aspect.

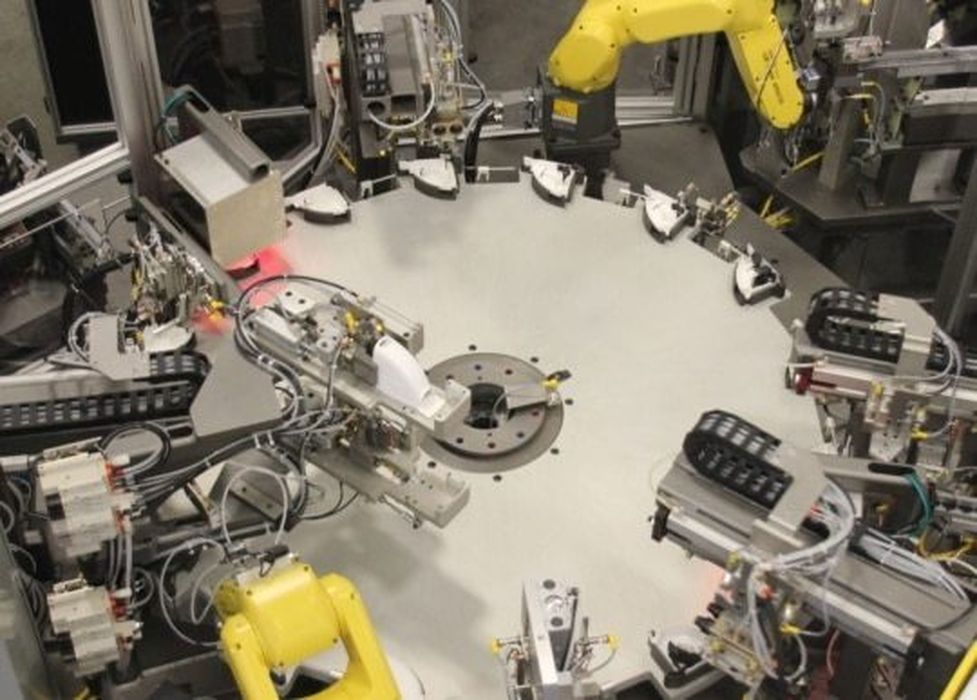

- Be flexible with your solutions. One shoe doesn’t fit all. Sometimes a hybrid solution is best. One of our CNC-machining clients, who thought they were converting to all robot automation, realized that a new CNC with more functions and some robots was a better combination.

Another client used a new cobot with a specially designed gantry to get the job done. One of our artisan fabricator clients realized that a used, modified industrial robot could do the trick. Consider 3D printing where new technological developments may provide new opportunities you weren’t aware of.

- Try to keep the new solution simple and elegant. If your team is faced with two alternative solutions, the simplest one is often the best way to go. Highly complex projects often have multiple factors and varying layers of inputs that are affected by a myriad of elements. To help your team get to the right result keep things simple.

- Contact your local Manufacturing Extension Partnership (MEP) to see if economic grants are available for improvements to your manufacturing processes and equipment. You may be surprised by how many opportunities your local MEP has to offer.

- Be a good communicator so that everyone understands the goals and objectives. Staff reduction is not a goal for our clients. Delighting the customer and efficiency is normally our clients’ main goal.

- Continuously test and model your new processes with small batches and pre-production runs. Our clients find prototyping an easy way to determine if both the process is running as it should and if the product is at all affected.

- Budget for training. Your team is going to need some education to implement the new processes. Your management team must accommodate for the time allocated to education and training.

- Finally: broadcast and celebrate your accomplishments and success and earn your R&D tax credits where applicable.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

There are many reasons for companies to automate their manufacturing and distribution processes. One of the main reasons is to increase efficiency and reduce cost. 3D printing can help achieve those results.