Polymaker announced a very intriguing new 3D print material called “PolyTerra”.

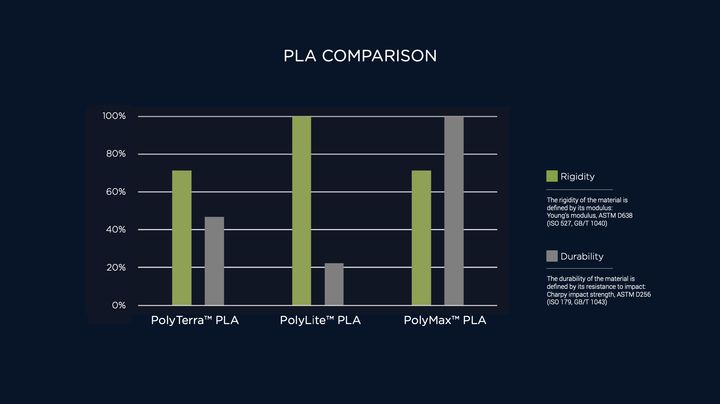

It’s a PLA material, and as you might expect it offers mechanical and thermal properties very similar to other PLA filaments, although it is said to be a bit more “tough” than plain PLA and similar to “tough PLA” materials.

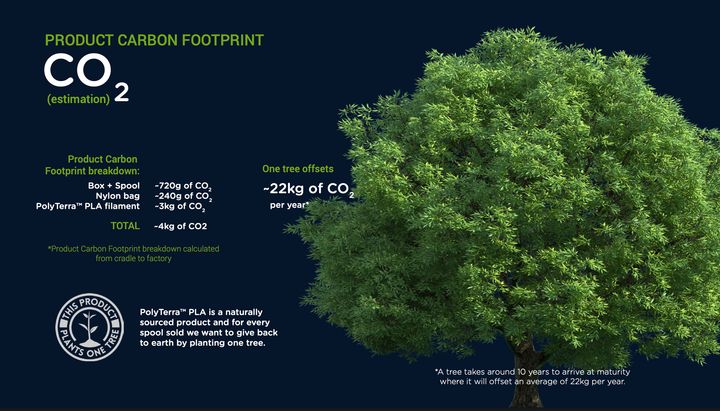

That’s not the magic part of PolyTerra. Instead, it’s how the product is produced and sold. It’s actually a carbon negative product. That means the net effect on atmospheric carbon is negative; there is less CO2 if you use this product.

How can this happen? Polymaker has taken several steps to get the product to this state.

First, the material itself is actually a combination of “naturally occurring organic materials” with normal PLA resin. They say it uses 40% less resin than used in pure PLA products.

I’m wondering what this mystery component is, as PLA is normally made from organic materials. However, as I understand it, making pure PLA requires extreme heating of organics, and perhaps that’s what Polymaker is avoiding here by directly including other organics.

Polymaker says the new components aid in the visual properties of prints made with PolyTerra:

“The naturally occuring elements compounded into PolyTerra PLA provide a matte surface finish on 3D printed parts which is enhanced by the fourteen carefully selected colors available. Polymaker has introduced four new pastel colors which display an extra matte surface and have the ability to absorb light on printed parts hiding the layer lines in a smooth surface.”

Polymaker says the new mix is also able to biodegrade more readily than pure PLA, which typically requires intensive industrial processes:

“Polymaker has run a compostability test (ISO 14855-1 ) with a third party laboratory. PolyTerra PLA has shown expedited compostability when compared to a PLA sample achieveing 76.9% degradation after 45 days in test conditions (58°C ± 2°C/~50% Humidity).”

Secondly, Polymaker has adapted the packaging. While it’s still shipped in a cardboard box, the spool itself is now also made from cardboard. This is a really good step, as every 3D printer operator I know of is awash in empty spools, typically made from CO2-generating materials. These new cardboard spools — which are made from recycled material themselves — can simply be recycled again. In addition, all the product information is provided online, so there’s no need for extra inserts or special labeling in or on the package.

Finally, Polymaker has made arrangements with a carbon offset provider, OneTreePlanted. The idea here is that for every PolyTerra spool sold, OneTreePlanted will plant a tree. As the tree matures, it absorbs CO2 from the atmosphere, said to be up to 22kg by the time the tree matures.

The net effect of all these moves is to create a 3D printer material that is literally carbon negative, yet the material is as good to use as any other 3D print material.

Polymaker says the new material offers easy-to-remove support material, and as you can see in these images, the prints look quite good.

Perhaps the most interesting twist to this material is the price: the MSRP for 1kg is only US$19.99! That’s less expensive than many premium 3D printer filament, and you get the environmental benefits, too.

This is a tremendous step forward by Polymaker, as it clearly shows that it is possible to make carbon negative 3D printer filament. While they’ve done this for a PLA material for now, it’s possible they may be investigating creating analogous eco-materials to replace other engineering filaments.

Via Polymaker