Charles R. Goulding and Preeti Sulibhavi look at some of the many space startups now leveraging metal 3D printing.

Most of us have seen the commercial space launches that took place in 2021. First there was the Virgin Galactic suborbital human space flight in May of 2021. Company founder, Richard Branson, hopped aboard the July 2021 mission. Then Jeff Bezos flew onto the suborbital scene in July 2021 in Blue Origin’s New Shepard. Star Trek’s William Shatner famously shot into space in the October launch.

SpaceX, which launched the Inspiration4 mission, the first orbital spaceflight with only private citizens on board in September 2021, successfully orbited the Earth at an orbit higher than the International Space Station (ISS) and lasted 3 days.

The aerospace industry is now replete with startups. In a recent Bryce Tech 2022 Update on Investment in Commercial Space Ventures, there were metrics that illustrated the depth of the magnitude of the industry growth in recent years. The report was 39 pages and highlighted dozens of space startups and their investors.

The Bryce report included a list of 2021 space startup acquirers by target company. The list included several aerospace startups that we have highlighted in this piece. Among several startups, were SpaceX, Rocket Lab, and Astra, among others.

SpaceX, and its founder, Elon Musk, have shot to fame because of its recent successful space launches. The Falcon 9 is a reusable, two-stage rocket designed and manufactured by SpaceX for Earth orbiting and beyond. It is the first of its kind and the ability to reuse the most expensive components of the rocket drives the cost of space travel for private citizens down.

SpaceX has 3D printed its building extensions at its Texas Starbase and it has invested in Velo3D and its metal 3D printers for rocket production and interplanetary construction.

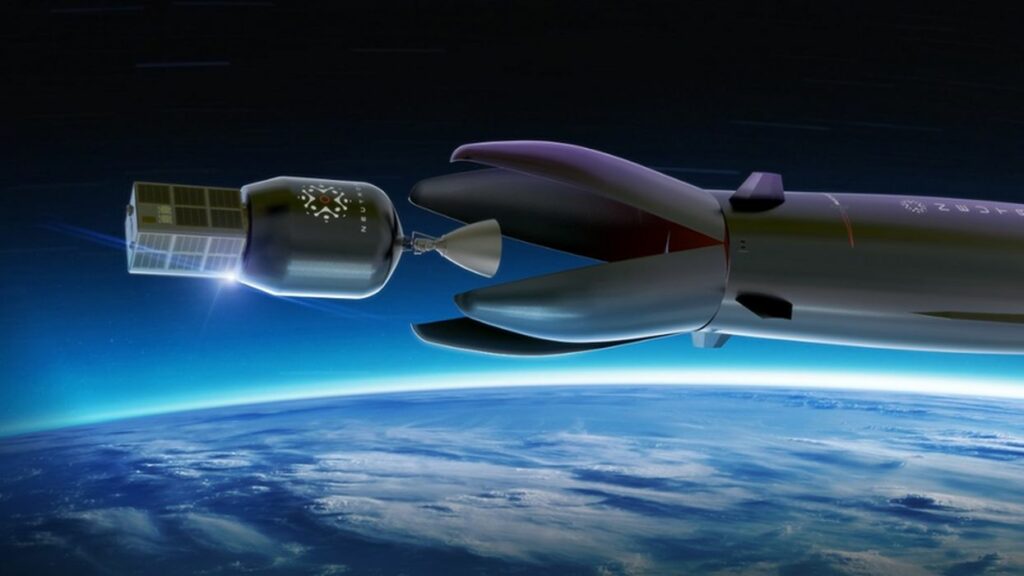

Astra is an aerospace company that prides itself on solving problems on earth and in space. Whether it is removing space debris or providing in-space cargo delivery service, Astra is changing the paradigm of in-space transportation.

Rocket Lab is another startup that is dedicated to small space launches offering dedicated and rideshare options, tailored orbits, scheduled controls and responsive launches, missions are delivered in the customer’s way. Rocket Lab’s Electron Rocket is powered by its 3D printed Rutherford engines and has passed initial system testing in order to launch a microsatellite from the US Air Force research laboratory’s Monolith program into space.

There is a myriad of ways the 3D printing industry can be a part of this trend. The best way is to get in on the investments early, during the startup phase, as the Bryce Tech report described.

There were several fledgling startups such as Relativity Space and Sierra Space that also appear to show promising results.

Relativity Space vertically integrates robotics, software, and patented 3D printing technologies to digitize manufacturing. Boasting that it goes from raw material to flight in 60 days, Terran 1, the world’s first 3D printed rocket, is the only medium payload launch vehicle engineered to adapt to the changing needs of satellite operators.

Sierra Space brings 3D printing in-house to take advantage of the flexible technology for its Dream Chaser spaceplane. It is a multi-mission utility vehicle for transporting cargo into low-Earth orbit destinations like the ISS. It is a reusable aircraft and has thermal tiles with matching chucks (tools that correctly position the tiles). Sierra has opted to 3D print the chucks instead of casting them.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies, including startups, developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Space exploration is not new, but commercial, private space transport of people and payloads is. It would benefit the 3D printing industry to launch into action and add to success of this emerging industry.