There’s apparently a new record set for the world’s fastest 3D printed #3DBenchy, but I have questions.

A video recently published by Monika McWuff shows the ubiquitous #3DBenchy being printed in only 2:09, which is slightly faster than her previous record, which was 2:19 according to the official #SpeedBoatRace entry spreadsheet.

Here’s the video of the new record entry:

Surprisingly, this was accomplished on a carefully tuned Ender-3 3D printer, as opposed to the highly engineered high speed 3D printers that otherwise dominate this competition.

However, there’s a problem.

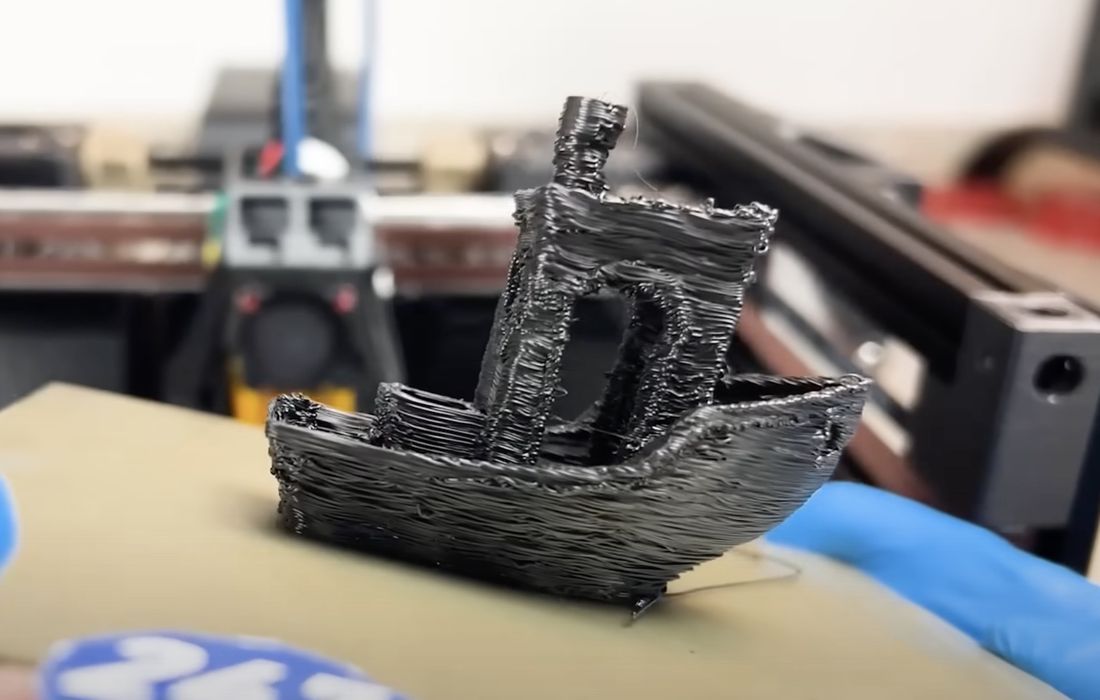

The quality of the #3DBenchy shown above for the 2:09 result is definitely not good. It is barely recognizable as a #3DBenchy.

This is the result of the next fastest machine, with a 2:25 result. It’s also not terrific in quality, but is far better than the 2:09 entry.

Commenters on the video also observed the quality issue, saying:

@ipadize: 99% speed 1% benchy

@CockatooDude: This is the 3D printer equivalent of forgetting to do your tedious assignment and then rushing through it 30 minutes before class starts.

@XY-ke4cu: The fact that at this speed machine did not disassemble itself and print actually looks more like benchy than just a blob of plastic is pretty impressive. Personally I’d rather go for more clean print than speedy one but still – good job.

I believe attempts like this really invalidate the entire idea of a competition: the point of a 3D printer is to produce a specific object. Here we have a print that vaguely resembles the intended geometry, and is clearly of a quality that no one would accept.

Yet, according to the rules of the race, it is a valid entry because all requirements were met.

It seems to me that the competition should really be about “print a #3DBenchy with a minimum quality at the highest speed”. If we don’t do that, then the leading entries will continue to degrade in quality while being printed ever faster.

Why so? It’s because 3D printing is actually a balance of many factors. Print speed, temperature and flow rate are all intimately related. A change in one could affect the others, and a good result occurs only when they are properly coordinated.

Here we have left open the possibility to unbalance the equation and produce questionable results. Why “questionable”? It’s because the result is of no practical use. A race to determine the fastest should tell us which machine can competently print an object in the least time. The way the race rules are set up does not really allow that to happen. Few, if anyone, will use the race results to help them choose a 3D printer.

Could we introduce a quality control component to the race? I think yes, and no.

3D print quality is a well known practice and is commonly done in industry. It’s called metrology. The object is measured and then compared to the desired geometry, and the difference is how good or bad the quality could be. Typically industry would reject any part that exceeds certain specified thresholds.

To add this step to the race would require each entrant to submit a 3D scan of their print result. A central analysis service would then compare the scanned geometry with the standard #3DBenchy geometry from CAD and compute the differences. The sum or average of the variations could be used to present a quality value for the attempt.

The rules could then be tweaked to require something to the effect of: “attempts must be within xx.xx on the quality measure to qualify.”

Would this work? Could it be implemented? Probably not for two reasons.

First, the quality of 3D scans would be wildly different if each submitter is doing so. Some would not even have access to 3D scanners, and operating them would be inconsistent.

Secondly, who’s running the central analysis service? It would not be appropriate to have entrants compute their own quality values because there would be far too much variation in tools and practices.

Without such measures, however, the challenge is of far less value than it could be.

Via YouTube