We had a chat with Ulendo, developers of an intriguing system to dramatically speed up 3D printing.

Ulendo is a company we’ve previously written about. In 2019 the company appeared as a spin off from research taking place at the University of Michigan. In 2020 they launched on Kickstarter, but the campaign did not reach its funding targets.

It seems that the company has switched gears since the Kickstarter and now focuses on companies rather than individuals.

But what’s their tech all about? It has to do with vibration.

3D printing is usually a tediously slow affair, where parts are slowly built, thread by thread, with FFF equipment. There’s always a need to speed up operations, and you might think it’s a simple matter of cranking up the motion system’s speeds.

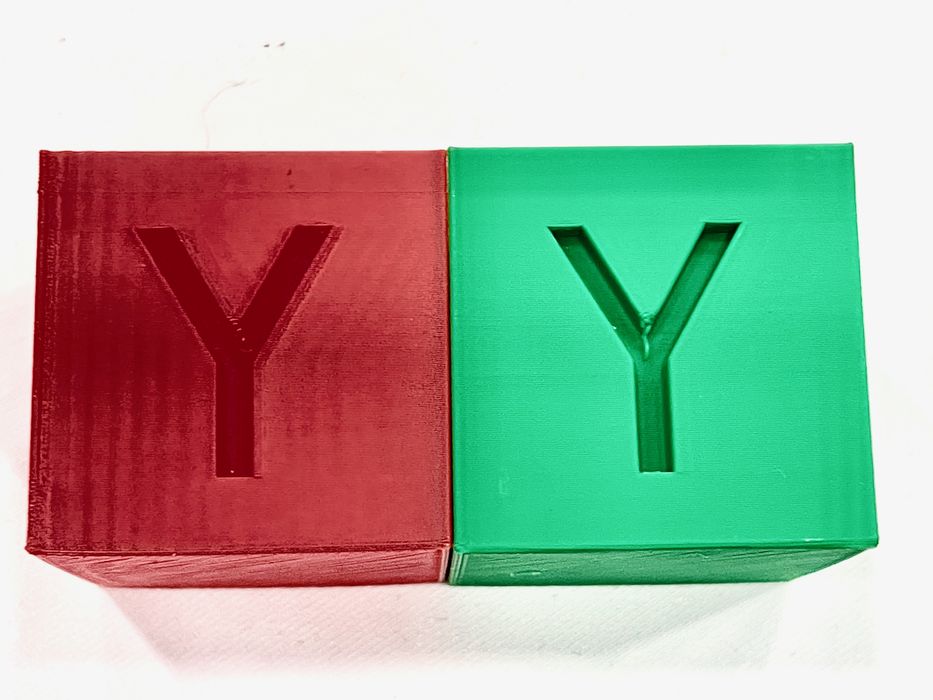

It turns out this doesn’t work because at higher and higher speeds the print head’s momentum overcomes the motion system when directional changes occur. These result in vibrations that corrupt prints, typically seen as “echoes” near corners where these movement changes occurred during printing.

Ulendo’s technology is to operate as a kind of “plug in” to the 3D printer’s firmware. GCODE is intercepted and adjusted to automatically compensate for the vibration, and thus the print speed can be raised significantly. Ulendo said they can typically achieve 2X print speeds (independently confirmed ) with their system.

There’s one issue: Ulendo has to first determine the “vibration profile” for a given piece of equipment. This is because the motion systems are all subtly different among vendors, and there is no such thing as a universal vibration profile.

This also makes implementation challenging for DIY 3D printer operators, who have a tendency to modify their machines to increase performance. Each time the machine is modified, there is a risk that the vibration profile will change and thus you’d have to start over.

This means Ulendo clients will tend to be 3D printer manufacturers seeking ways to speed up their equipment’s print speeds. The manufacturer will produce identical machines, all with the same vibration profile. They can then be equipped with the Ulendo package to enable speed increases.

Ulendo told us they have secured their first client: Flashforge. The well-known Asian manufacturer will at some point release speedy 3D printers that make use of Ulendo tech under the covers.

Ulendo definitely works, at least according to my eyeballs looking at the sample prints I was shown. It seems to me that 3D printer manufacturers seeking a way out of the competitive traffic jam could partner with Ulendo to gain a print speed advantage.

Via Ulendo