I have a further update on the situation involving Sprybuild, a startup company offering a unique resin 3D printing system.

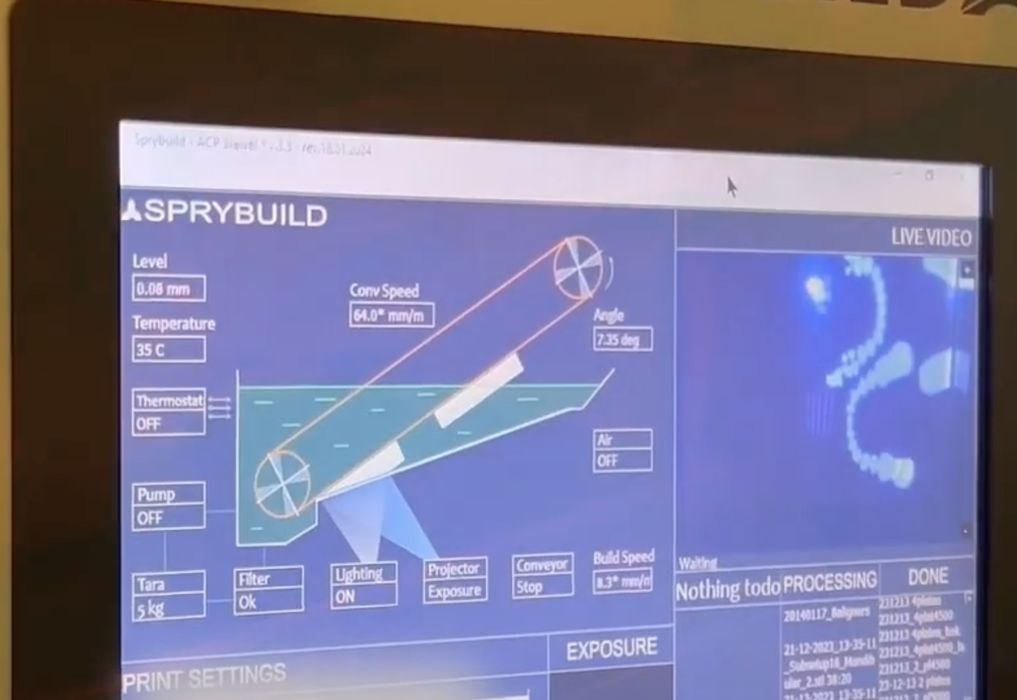

Last month the Israel-based company emerged with a very intriguing 3D printer concept: a resin 3D printer with a conveyor belt as the build plate. This allows the device to print objects, and then roll them off the belt. This cleans the “plate” for subsequent jobs, meaning this is a continuously printing device.

Another important feature on the 3D printer is a means of high speed resin 3D printing. Normally resin 3D printing is quite slow because each layer has to be carefully “peeled” of the resin vat because of adhesion. Sprybuild has developed an undisclosed method of avoiding the adhesion, making the prints proceed far faster. You can see how this works in this short video of an early prototype:

The 3D printer has not yet been released, and as far as I can tell, hasn’t even got a product name yet.

After our original story, we were contacted by readers who felt that the conveyor belt system might be similar to a previously patented 3D printing method involving a conveyor belt.

If one looks closely at the two systems, there are similarities, but also differences. It’s not clear to me whether this could be considered infringement of the original patent. However, the comments suggested there might be a risk of a patent conflict.

I contacted Sprybuild for comment and spoke with CEO Oleg Khalip. He said:

“We believe that the assumption of infringement is a misunderstanding due to the presence of common features (conveyor) and the lack of full information about our technology and device, which we do not disclose until the completion of patent application procedures.”

It seems that Sprybuild has already submitted no less than three patent applications for their design. Khalip continued:

“We have already received positive search reports for two applications. In accordance with the PCT rules, we wish to exercise our right not to disclose the content of our patent applications until their official publication and until the completion of related applications.”

Regarding the potential infringement that was suggested, he said:

“The method and device described in the patent you mentioned do not contain the entire set of essential features of the method and device of our presented printer and our filed patent applications, while the differences are radical and non-obvious and lead to outstanding technical results.”

What methods might be described in these patents? Khalip offered some hints, but nothing specific:

“As we continued our work, we realized that the list of problems in the resin 3D printing industry was much broader: beyond low speed, there were issues such as labor-intensive pre-processing, insufficient repeatability of products, fluctuations in mechanical properties, a severe lack of post-processing automation, waste and pollution from support structures and used washing solutions, numerous auxiliary equipment, and more.

We set ourselves the ambitious goal of solving all these problems. Seven years and $800,000 of our own funds later, we can say that our international team has a solution for each of the listed issues.”

It appears that their patents could be related to the solutions described by Khalip. If they have indeed fixed those issues, the 3D printing industry would certainly be quite interested. As someone who performs resin 3D printing myself, I can say all of Khalip’s problems are quite true — and very annoying.

Khalip went on to say that the company’s intention is to deliver a ”fully automatic manufacturing process realized in a concise production system” to the market at some point in the future.

Via Sprybuild