Selective Absorption Fusion technology is at the heart of the new Stratasys H Series Production Platform.

Stratasys SAF 3D Printing

SAF is planned for commercial availability in Q3 of this year. The powder bed fusion tech is taking aim at volume manufacturing. The announcement explains:

“The SAF technology uses a counter-rotating roller to coat powder layers onto a print bed and prints absorber fluid to image the part layers. The imaged layers are fused by passing an IR lamp over the entire span of the print bed. SAF technology executes these key process steps in the same direction across the print bed to provide a uniform thermal experience – and therefore part consistency – for all printed parts regardless of their placement in the build.”

And:

“SAF technology is used to selectively jet high energy-absorption HAF fluid onto areas of a layer of powder-form material in just one full-width pass. Industrial piezo-electric print heads jet single or multiple drops of the fluid to produce either fine detail or large areas, without compromising throughput. The technology supports unique, high-specialty, functional fluids to process a broad range of powders. Infrared energy is radiated to fuse the selected areas and the underlying particles. Tight thermal control avoids warping, quality fall-out, and reduces peak temperatures required in the bed, making SAF technology ideal for production.”

A powder management system — Big Wave — is another intriguing piece of the process. Big Wave ensures full print bed powder distribution, recirculates overflow powder, and overall ensures material control.

As far as materials go, Stratasys notes that SAF “is inherently able to process a wide variety of materials, such as polyamides and elastomers.” This fits well with PBF technologies. Again in something that’s still a bit of a newer move from Stratasys, the company also explains that its “relationships with leading chemical companies will help it bring new materials to market quickly.” It’s nice to see the long-time proprietary materials company working with partners on perhaps less closed systems.

Stratasys x Xaar 3D

The SAF process seems to be the new styling for HSS — the High Speed Sintering technology Stratasys has been working with Xaar on for some time now.

Xaar, which develops piezoelectric drop-on-demand inkjet technologies, has seen notable involvement with Stratasys, from founding to a significant investment. Stratasys owns 45% of UK-based Xaar 3D. In September 2020, Xaar’s interim results report indicated moves toward commercialization:

“With the strategic direction of the 3D business unit established following the increased investment in Xaar 3D by Stratasys in December 2019, the focus has been on executing this strategy. For 2020 this means the successful testing of machines manufactured by our sub-contract manufacturing partner, shipping machines to Stratasys for beta trials and establishing the go-to-market teams and infrastructure prior to product launch. Despite some delays linked to COVID-19, testing has gone well and plans for the product launch are well underway.”

So it would seem the new H Series is that long-time work coming to fruition.

While today’s announcement doesn’t specifically highlight much about Xaar 3D, in a couple weeks more will seemingly be revealed. A “live conversation on LinkedIn and Facebook” set for April 7 will bring together Xaar 3D Director of Technology — “and original inventor of the technology behind SAF” — Professor Neil Hopkinson with leaders from the Stratasys side. At that virtual event, more details will be offered for the tech and its development history, as well as its placement within the ever-growing Stratasys portfolio.

Today’s announcement also says that more information about SAF is available at this link, but as of the time of writing, that link has not worked yet for me. Hopefully soon.

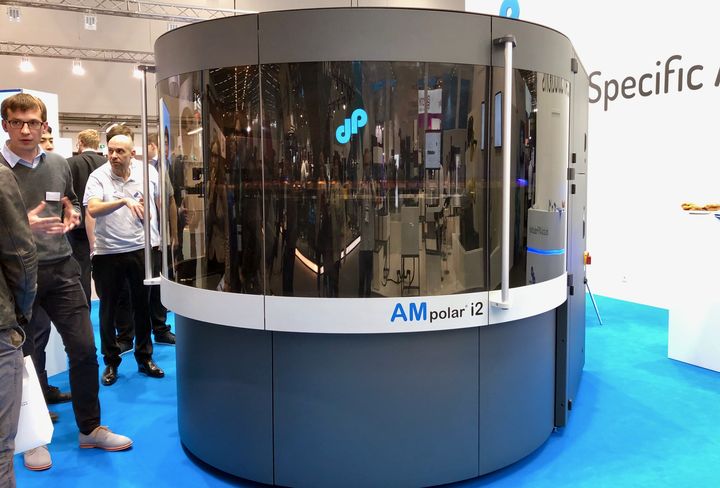

We also don’t yet have an image of the first H Series 3D printer aside from the control panel view above; could the full system look something like another we’ve seen incorporating Xaar’s printheads? Unlikely, but hm.

Stratasys’ Production 3D Printing Strategy

SAF is, clearly, another piece in the production puzzle for Stratasys’ portfolio.

Every move the company is making lately has been focusing on filling out more of the company’s expansive portfolio. Much, if not all, focus has lately been on production polymer 3D printing. Indeed, EVP of Product Strategy and Corporate Technology Omer Krieger says:

“3D printing is increasingly transforming production in industries around the world as companies seek to move with more agility and efficiency, which is why we have put production parts at the heart of our business strategy. SAF technology represents a significant innovation that opens up new opportunities to address applications in industries such as automotive, consumer goods and electronics, and industrial equipment. As a result, we will enable a shift of many applications from traditional manufacturing and also enable the creation of products that can only be produced additively.”

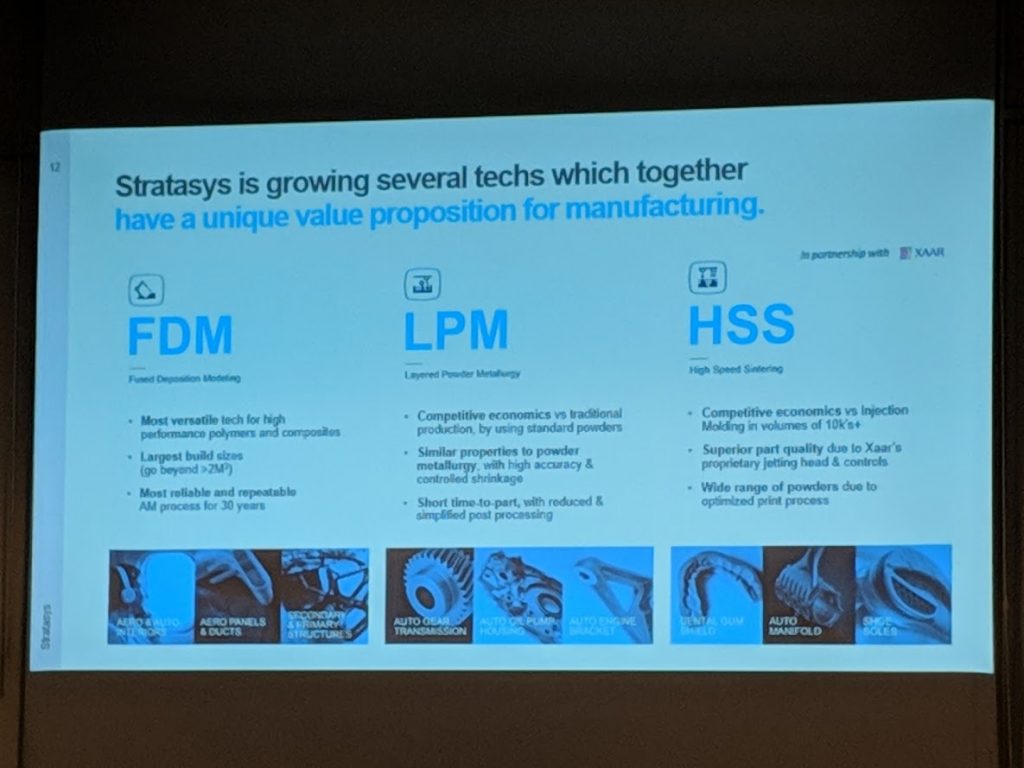

It’s been interesting to watch Stratasys’ production focus evolve. At Formnext 2018, the company highlighted three technologies as being key to its strategy:

- FDM

- LPM

- HSS

That list may look a bit different now in 2021, as we haven’t heard much about Layered Powder Metallurgy in a little while. Much more focus has been on the polymer side, with acquisitions bringing in SLA and DLP technologies and more advances in PolyJet and FDM and, now, HSS/SAF.

Via Stratasys

This sounds promising! I’m looking forward to hearing more about the available materials for this. If HAF works with most polymers, I’m guessing the only major disqualifier would be their thermal expansion. Fusion temperatures tends to come with a lot of warping (of course, not so much for small parts but this is Stratays we’re taking about).