Stratasys and DyeMansion announced a new strategic alliance that combines capabilities to provide an end-to-end full color additive manufacturing workflow.

This would at first seem to be a strange partnership, as the two companies had very little intersection in the 3D printing world.

Stratasys produced 3D printers using two processes: FDM and Polyjet. DyeMansion produces post-processing equipment mostly used on SLS 3D prints. How could they connect?

Stratasys H350

That all changed in the past week when Stratasys unveiled not one, but three new 3D printers in a blockbuster announcement. Among the three machines revealed on that day was the H350, a production device using a process new to the market.

The H350 is not a FDM or PolyJet 3D printer, and also not an SLS device. Instead it uses a process originally developed by Xaar called SAF, or “Selective Absorption Fusion”. It’s a process involving high-speed inkjet-style droplets selectively deposited on the powder bed. A heat cycle then fuses the wet portions, and the process repeats, layer-by-layer.

SAF is not SLS, but the end result is a fused powder object, one very similar to those obtained with the SLS 3D printing process.

DyeMansion Process

DyeMansion began as a company providing a means to reliability dye SLS 3D prints. Typically SLS 3D prints made on larger commercial equipment are white nylon. This is an ideal base from which to color the prints using dye, and many companies require color for their production SLS parts.

DyeMansion’s color systems can reliably reproduce target colors, batch after batch, making it an ideal solution for environments producing end-use SLS parts.

DyeMansion also produces other types of finishing equipment for the SLS process, including systems to wash off stray powder after 3D printing completes, as well as systems to refine the surface finish on prints.

Their strategy is to provide a complete post-processing lifecycle for powder-based 3D prints, and their solutions have become key parts of the production infrastructure for many AM companies.

Stratasys — DyeMansion Alliance

While Stratasys has targeted the new H350 towards production applications, there was definitely a gap. By itself, the H350 is suitable for producing end-use parts — in one color only. That’s a definite drawback for many potential buyers who require specific colors for their production line.

Similarly, the H350 is only a 3D printer, and is unable to perform mechanical post processing such as washing and surface finishing.

Stratasys had to fill the gap, and the fastest way to do so would be to partner with a company already performing this work at an expert level. That partner has turned out to be DyeMansion.

DyeMansion explains the arrangement:

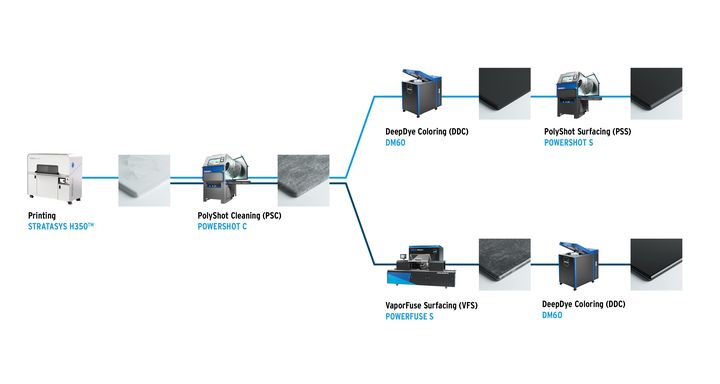

“The DyeMansion Print-to-Product workflow complements the H350 printer with an industrial solution for cleaning, surfacing, and coloring parts. Depending on the end-use application requirements, customers can choose between two different finishes: an aesthetic semi-gloss finish delivering a homogeneous scratch resistant surface, or a more functional finish delivering completely sealed and washable surfaces. The Print-to-Product workflow enables various applications such as eyewear, automotive interior or spare parts, and medical devices and orthotics.

The Stratasys and DyeMansion alliance has allowed the companies to combine their mutual expertise and industry knowledge to not only create the reference architecture, but to produce a unique, sustainable solution for cleaning, chemical smoothing and dyeing. Manufacturers can now move their parts from print to post-process through an integrated offering that drives greater value and offers a unique solution compared to those on the market today.”

How will the new architecture be deployed? It seems that the partners will first install a reference system at Stratasys’ own manufacturing service, Stratasys Direct. There it will be used to produce finished H350 parts for requesting customers, as well as serving as an example for clients considering setting up their own H350-DyeMansion production system.

For Stratasys, this alliance immediately makes the H350 system much more attractive to potential buyers. For DyeMansion, it provides another channel through which new clients can be exposed to their advanced post-processing technology.

This could be only the start, as Stratasys’ long-term strategy is to move strongly into production manufacturing environments. The H350 and the other new equipment announced are only the beginning of that transformation. It’s a massive move for Stratasys because the world of manufacturing is vastly larger than the prototyping world where they began years ago.

As Stratasys expands their manufacturing footprint n the future, we should expect to see further equipment appear in Stratasys’ H series, likely including much larger equipment.

And DyeMansion will be traveling along with them.

Via DyeMansion and Stratasys