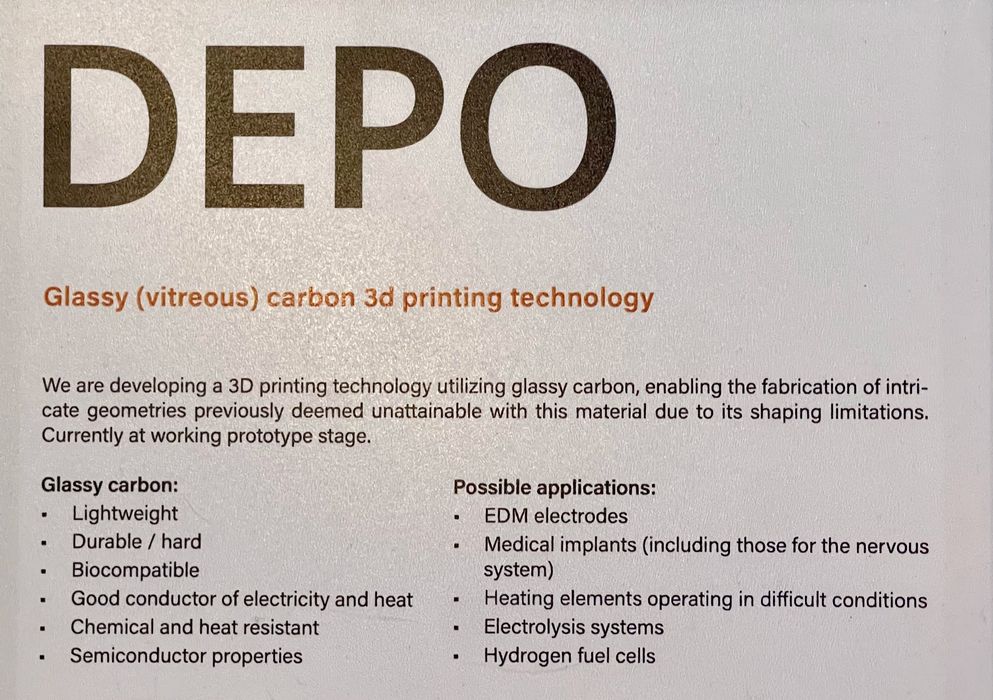

Sygnis has developed a new process to 3D print “glassy carbon” they call “DEPO”.

I had never heard of glassy carbon either. What is it? Wikipedia defines it as follows:

“Glass-like carbon, often called glassy carbon or vitreous carbon, is a non-graphitizing, or nongraphitizable, carbon which combines glassy and ceramic properties with those of graphite. The most important properties are high thermal stability, high thermal conductivity, hardness (7 Mohs), low density, low electrical resistance, low friction, extreme resistance to chemical attack, and impermeability to gases and liquids. Glassy carbon is widely used as an electrode material in electrochemistry, for high-temperature crucibles, and as a component of some prosthetic devices.”

The company has previously been involved in unusual glass 3D printing technologies, so it’s not that big a surprise they are exploring that niche a bit further with glassy carbon.

Sygnis defined the material as “diamond lite”, as it is extremely hard.

The idea is to create a technology (DEPO) that can shape glassy carbon in ways that were not previously possible with conventional making techniques. This is similar to what happened in polymer and metal 3D printing worlds, but here it’s happening again with glassy carbon.

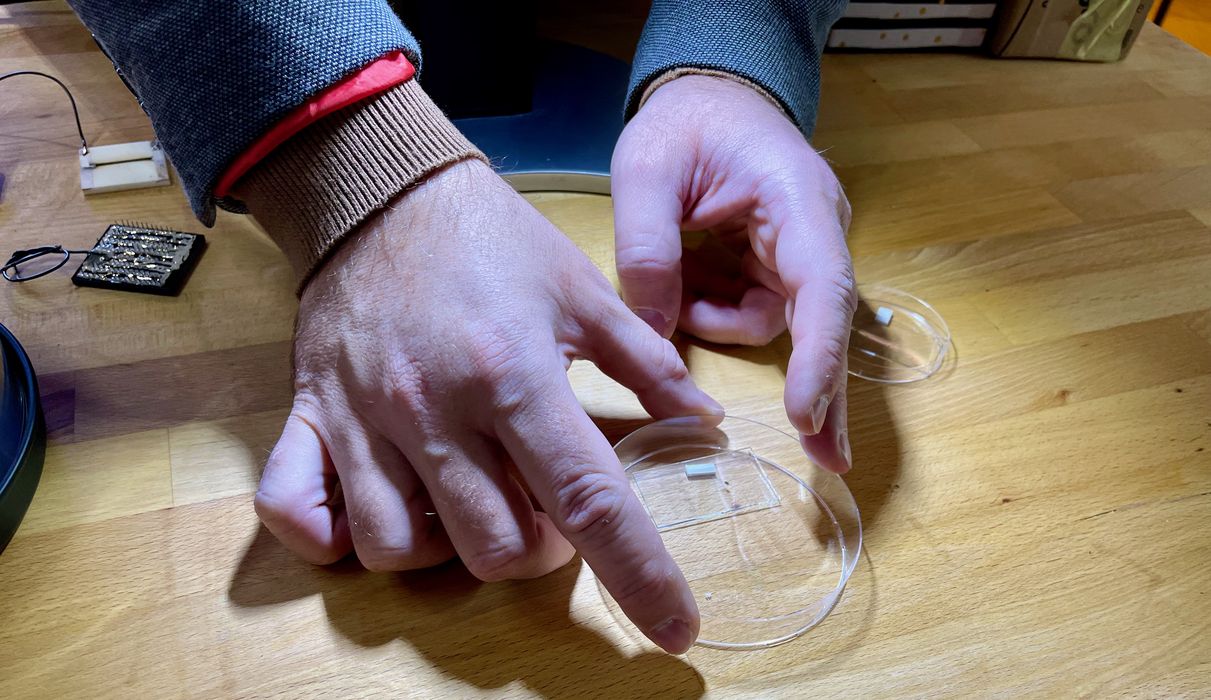

Here you can see a microscopic view of the print. Hint: it’s in the glass dish, and it’s extremely small.

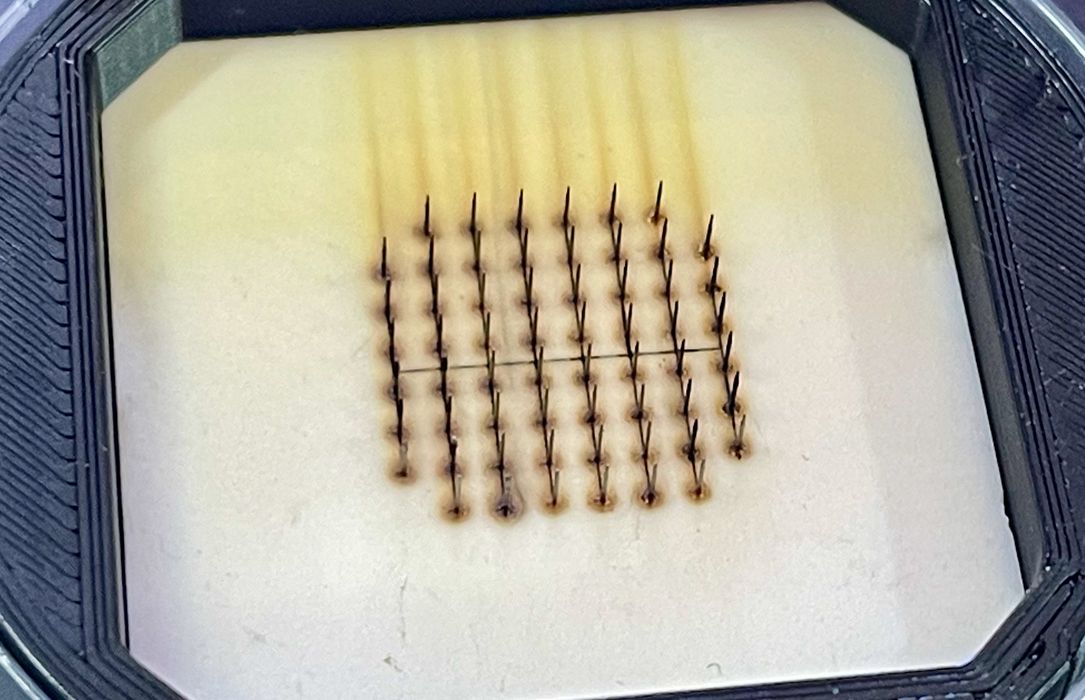

This item is a bit more visible; it’s a series of electrodes that can be hooked up to a power source and generate hydrogen from water. The tiny size of these electrodes means the process can be more efficient due to the electrode density.

I asked Sygnis about the process they use in DEPO, but they couldn’t tell me much due to secrecy. However, they did say it involved a specific vented gas, a source of carbon and a way to selectively hit the surface.

The process at the moment is suitable for producing small objects, as you’ve seen above. While small, these can be quite powerful in the right type of electric application.

Via Sygnis