I’ve just encountered yet another construction 3D printer, and this one is a bit different from the others.

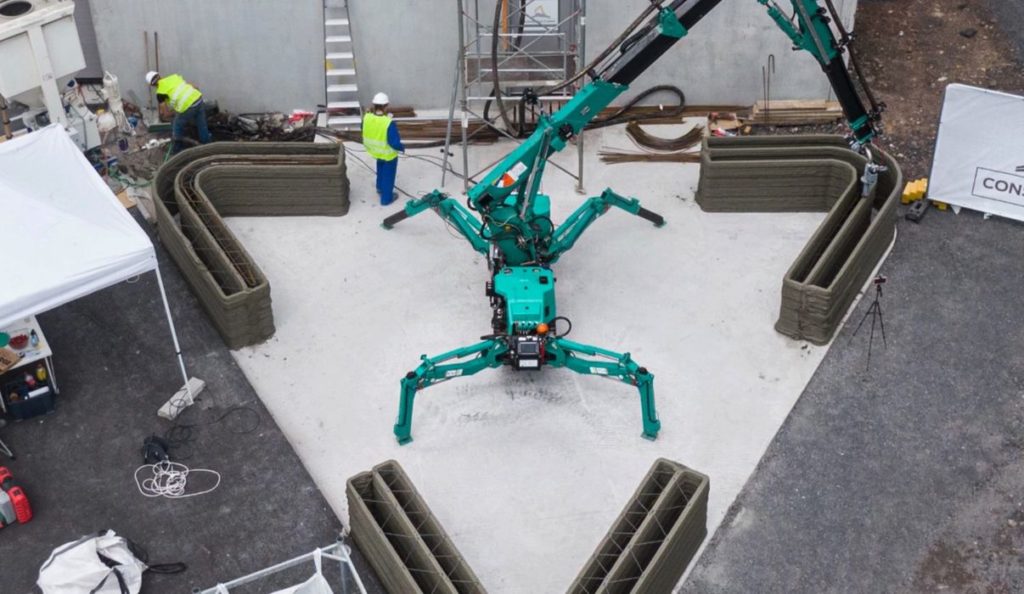

The machine is called the “Maxi Printer”, made by Constructions 3D. The company, located in the north of France quite near the Belgian border, has been in existence since at least 2014, and wishes to “enable humanity to find decent housing”, with limited affect to the environment.

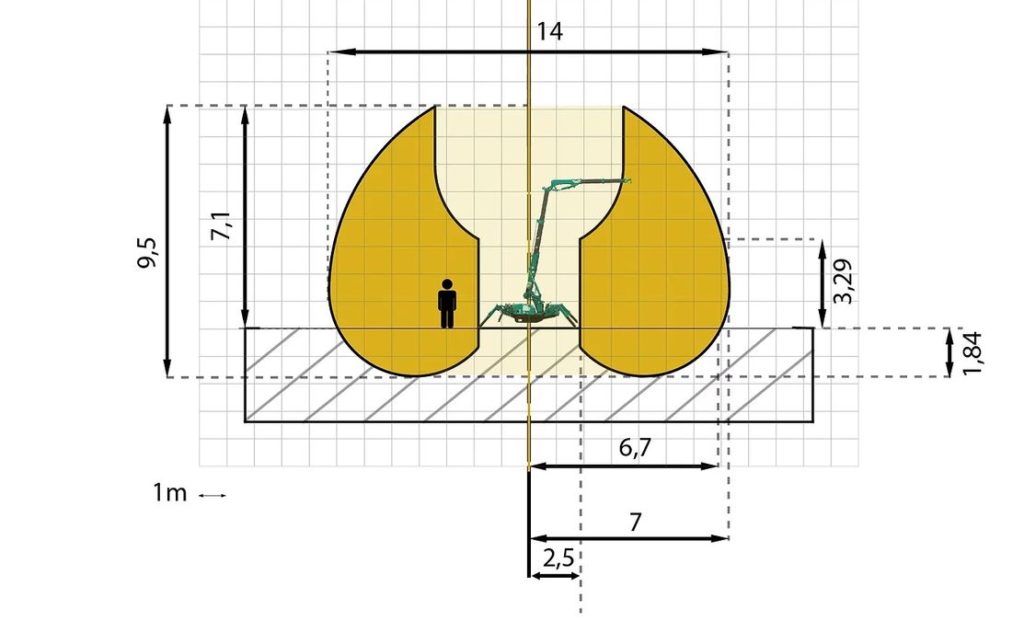

Like most construction 3D printers, the Maxi Print is a concrete extrusion system capable of handling concrete mortar. The system has a large build volume that is illustrated in this chart (note measurements are in meters):

This is not the standard cartesian build volume, nor even a cylindrical build volume that is most often used for such measurements. Here we have a very unusual non-contiguous build volume composed of two segments. What’s going on here?

The answer is that the build volume is essentially the zones that can be reached by the system’s robotic arm. This offers a significant build volume, but extendable if the printer is relocated appropriately. For specifications, they cite 9.5 x 9.5m as the build area, with a maximum height of 3.3m. Structures can be built to an accuracy of 5mm, which is more than sufficient for this type of construction.

That is the secret to the Maxi Printer: portability. Unlike the massive cartesian construction 3D printers used by others in this segment, the Maxi Printer is its own platform. It merely needs to reach the area to print. This eliminates the need for a significant setup time that often occurs with larger cartesian systems.

Constructions 3D explained the set up time for the device:

- Deployment and installation: 2 people x 60 minutes

- Printer and pump initialization: 2 people x 60 minutes

That’s it: Then you are printing. Tear down of the Maxi Printer takes two people only 90 minutes, whereupon it could be easily relocated to extend the build area.

There’s another interesting feature: the Maxi Printer and associated equipment is transported in a standard 20ft shipping container. This makes it incredibly easy to move the printer configuration to wherever it is required, since shipping containers can be moved by truck, rail or even ocean-going vessel.

I believe Constructions 3D is on to something here, as the setup time could be a barrier to some operations considering construction 3D printing.

Their concept is quite intriguing, and I’m wondering why it has not caught on. It may be that the company is under-financed, as there are now several competitors with very significant funding at their disposal. Thus it could be challenging for Constructions 3D to catch up.

Nevertheless, it is a very interesting construction 3D printer configuration.

Via Constructions 3D