Stratasys, KeyShot, and the 3MF file format come together for a stunningly realistic prototyping capability right off the 3D printer.

To get the right mix of qualities in 3D printing, the right ingredients need to come together. That involves not only the well-known big parts — hardware, software, and materials — but also the spices to get the flavor just right: expertise and file format.

3D Printing With 3MF

It’s hardly a secret these days that STL, OBJ, VRML, and other legacy file types are no longer the best options in 3D printing. The technologies available today have far outstripped those early processes that emerged alongside earlier files. A lot of focus on the software side of things lately has been on ensuring that these capabilities keep up with what hardware could potentially do. And that’s where we’ve seen 3MF come in and really start to shine.

This newer, far more capable format is coming more and more to the forefront in 3D printing these days. Efforts have been led by an interdisciplinary 3MF Consortium. There’s a lot of brainpower behind the Microsoft-led consortium and the .3mf is becoming a more common sight.

Over the years, the consortium has “come a long way in terms of defining a specification that’s technically very complete, very focused on the challenges and benefits 3D printing brings to the table,” Luis Baldez, 3D Printing Market Development, Senior Manager at HP and recently appointed Executive Director of the 3MF Consortium, told me earlier this year. His focus now in leading the 3MF charge is a big one: adoption.

Some big names in 3D printing have already adopted the file type, and integrations are widening. The power of such occurrences means we’ll see more advanced 3D print jobs happening. As more big names use it, 3MF will continue to proliferate and become more common. Along with it, capabilities expand — and broaden.

Stratasys x KeyShot

Today, Stratasys has announced a new integration focused on enhancing the simulated color, material, and finish — CMF — for a design prototype. No surprise, 3MF plays a big role here.

This spring, Stratasys introduced its office-friendly J55 3D printer, which can print with five materials (and a support material) in almost 500,000 colors, with Pantone Validation. The J55 and J8 Series 3D printers now offer support for KeyShot 10 3D rendering software from Luxion that makes for a powerful combination. Stratasys’ release today explains:

“The full-color, multi-material Stratasys 3D printers and the latest version of KeyShot from Luxion both now support the new 3MF file format, a significant improvement over legacy STL, OBJ, and VRML files. By saving designs to 3MF, KeyShot 10 produces files ready for printing, with accurate colors and bump/displacement maps to three-dimensionally simulate textures like fabric and wood. Additional enhancements are planned for 2021.”

And:

“Stratasys estimates that 3MF support with KeyShot can reduce 3D print modeling time of CMF models to a single day, while traditional modeling for final iterations can take from one to three weeks. The new workflow enables the CMF design phase to start earlier in the design process, helping bring new products to market faster, and also keeps modeling in-house to reduce risk of intellectual property loss.”

As an example of the streamlined workflow here, Luxion Vice President of Product and Strategy Derek Cicero notes that automatic UV Unwrapping, baking, and file packaging are now a one-step process. This, he says, allows “easy, fast, and intuitive 3D printing.”

For as much as we love to talk about production 3D printing, we need to remember prototyping remains a massive application area. When 3D printing concept designs, making the workflow smoother while making results better is a major time-, money-, and headache-saver.

Hands-On With Advanced CMF

It all sounds nice, sure, but the proof is in the pudding. Product development company Priority Designs is among the beta users of KeyShot 10 offerings for their J55.

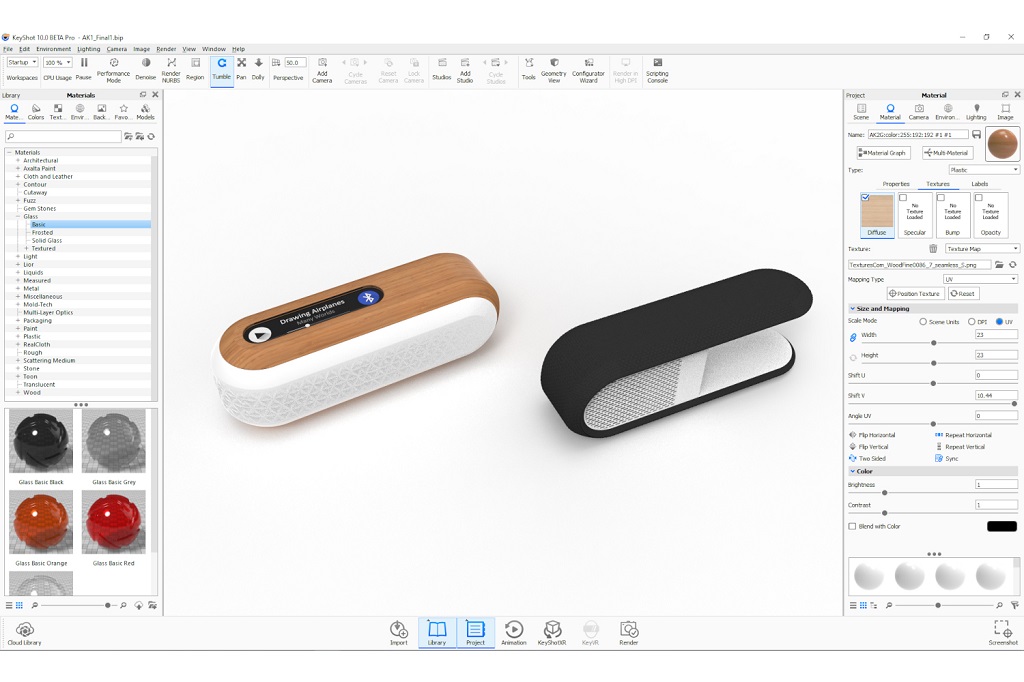

They put the new capabilities to the test in a new Bluetooth speaker design, as they explain in this video:

The Priority Designs team 3D printed five different models with five different wood samples and different fabric samples overnight. Having a fully-realized, fully-recognizable model to get hands-on — including speaker texturing — is a critical step toward enhancing the product development process.

And the photos throughout this piece? Those are from the speaker prototype Stratasys sent over so I could get hands-on myself.

“3MF file formats enabled the file to be exported directly from KeyShot into GrabCAD Print, which allowed for excellent color and texture accuracy,” the info card included with the piece explains.

This model was 3D printed in 5 hours and 40 minutes, and used 560g of various materials including VeroCyanV, VeroMagentaV, VeroYellowV, VeroPureWhite, and VeroUltraClearS, along with 278g of SUP710 support material.

“The J55 made true full-color, multi-material 3D printing accessible to design studios everywhere, but to fully transform how products are designed, we needed to make the whole workflow simple,” said Stratasys Vice President of Design, Shamir Shoham. “Adding KeyShot support in our PolyJet 3D printers adds an additional advantage compared to designers who are only using 3D printing for concept designs and turning to slower and expensive traditional models for detailed designs.”

Via Stratasys, KeyShot, and Priority Designs