Charles R. Goulding and Christopher Lee look at the increasing use of metal 3D printing in the nuclear industry.

Nuclear Power

Over the last few years, clean energy has certainly been a hot topic.

With carbon emissions at an all-time high, governments all over the world have been scrambling to find ways to reduce these emissions. This has led to a dramatic increase in investments in wind, solar, and hydroelectric power. However, another form of clean energy has existed for decades.

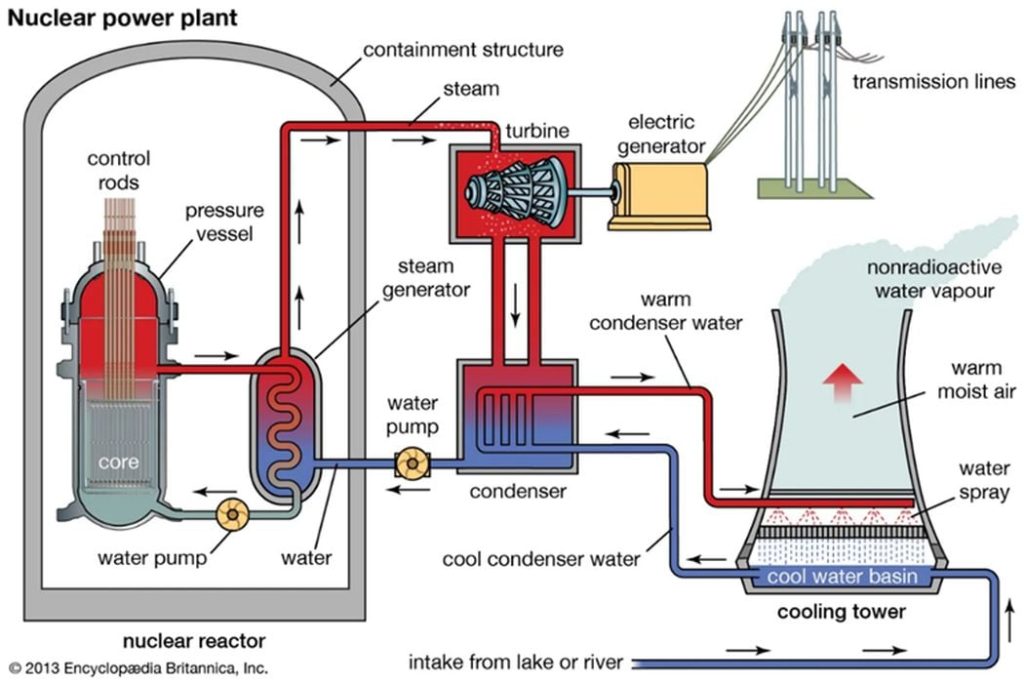

This form of energy is harvested through a process called nuclear fission where fissile nuclides capture low-energy thermal neutrons. The energy that is released through this neutron capture is used to produce steam, which is then used to spin a turbine. The turbine then spins an electric generator, which allows this energy to be utilized by the general population.

This process is colloquially known as nuclear energy generation, and it is as controversial as it is promising.

A large amount of this controversy is based on public concerns regarding the safety of nuclear energy, which has had its fair share of ups and downs throughout the years. However, a great deal of resources has been dedicated to making this form of energy just as safe as any other form of energy.

These strides toward safety have made nuclear energy a hot topic for designers and manufacturers alike. Perhaps one of the most promising areas of innovation is in the realm of 3D printing, where the ability of additive manufacturing technology to produce highly complex part designs in metal are already being used to print a variety of different reactor components.

Standardization

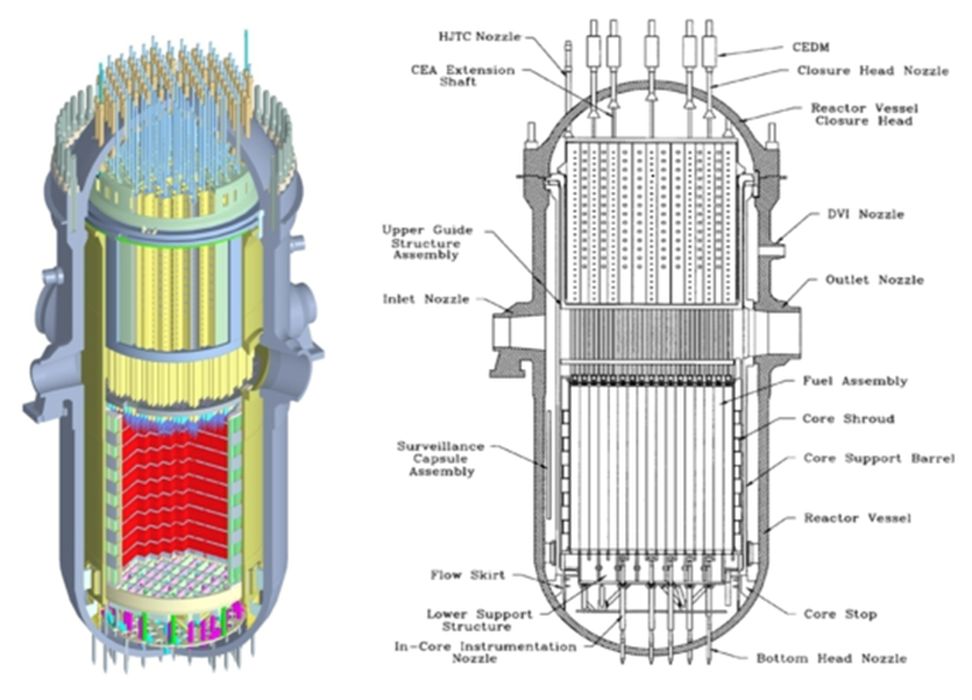

Nuclear reactors represent some of the most complex designs ever accomplished in engineering. As a result of this inherent complexity, there has been a push to standardize components within nuclear reactors to further bolster reliability, efficiency, and safety.

Standardization in this context involves fitting reactors worldwide with many of the same design elements, to ensure engineers and scientists can make well-informed decisions when evaluating nuclear reactors.The benefits of standardization can be broken down into four basic tenets:

- Design and Licensing Efficiency – Using a standardized design reduces the resources that must be dedicated to achieving licensing.

- Design and Safety Reviews –During safety reviews, it can be very convenient for regulators to not have to focus on analyzing major design elements and this allows resources to be devoted to more thorough design and safety reviews.

- More Stable Supply Chain – During the construction phase, challenges related to processes, codes, and standards benefit from standardization.

- More Efficient Product Life Cycle –Throughout the life of a nuclear power plant, a multitude of improvements can be made to plant processes. Standardized designs mean that improvements can be implemented across several plants.

This push for standardization represents a great opportunity to 3D print reactor components. 3D printing could bolster supply chain stability, by further standardizing the manufacturing process. Benefits could also exist with regard to things like safety reviews and product life cycles, as printing components using a repeatable methodology could streamline reviews and future improvements.

3D Printed Reactor Components

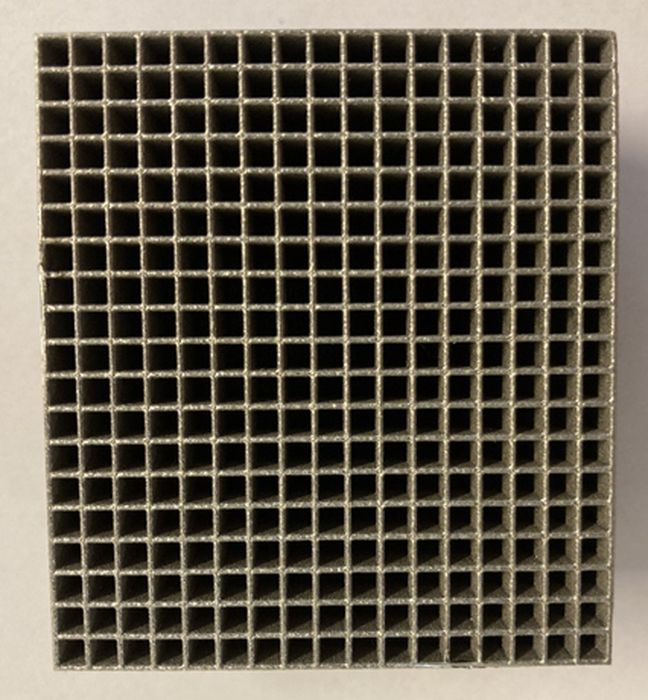

It looks like we won’t have to wait too long to see nuclear power plants that are utilizing 3D printed design elements. Forsmark Nuclear Power Plant in Sweden is utilizing a 3D printed steel upper tie plate grid atop its ATRIUM 11 fuel assembly.

US-based Oak Ridge National Laboratory (ORNL) has also thrown its hat into the ring, with its design of a 3D printed nuclear reactor core through the Transformational Challenge Reactor Demonstration Program. They hope to activate a reactor that utilizes this core by 2023.

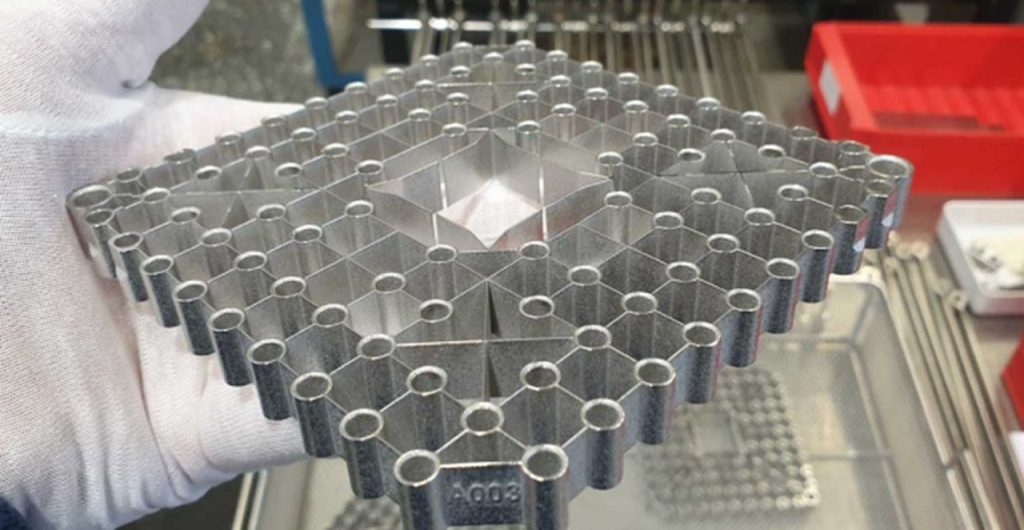

In 2022, Westinghouse installed a 3D-printed fuel debris filter in two Nordic Boiling Water Reactor units. These filters are fully manufactured through 3D printing and offer high levels of protection from debris within the fuel assembly.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

The Nuclear Landscape is Changing

It is said that some of the most important innovations happen during the most troubling times. With the war in Ukraine in full swing, the world’s energy landscape is drastically changing. This has led many countries to reconsider their stance on nuclear energy.

Most recently, German Chancellor Olaf Scholz reversed course and made the decision to continue running Germany’s three last remaining nuclear power plants until April of 2023.

We are also seeing renewed investments in nuclear energy, like French state-controlled power operator EDF’s €800M bid to purchase a nuclear turbine manufacturer from General Electric. These GE turbines are currently the most powerful nuclear steam turbines in operation, with the ability to output up to 1,900 MW at 50 or 60 Hz.

Brookfield Renewable Partners and Cameco Corp. are also expected to close on a deal to purchase Westinghouse, which would create a western nuclear powerhouse. Acquiring Westinghouse would allow Brookfield Renewable to inherit Westinghouse’s additive manufacturing resources, which would further bolster its offerings. The revival of the nuclear industry is coinciding with major improvements in 3D-printing technologies. This new paradigm presents fresh and exciting possibilities that should certainly aid future progress.