Charles R. Goulding and Preeti Sulibhavi discuss Thermwood’s impressive portfolio of patents.

The recent front-page, “Apple-Masimo” lawsuit for blood pressure applications on the Apple iWatch, has put patent strategy in the national news. We are impressed with Thermwood’s execution of its patent strategies.

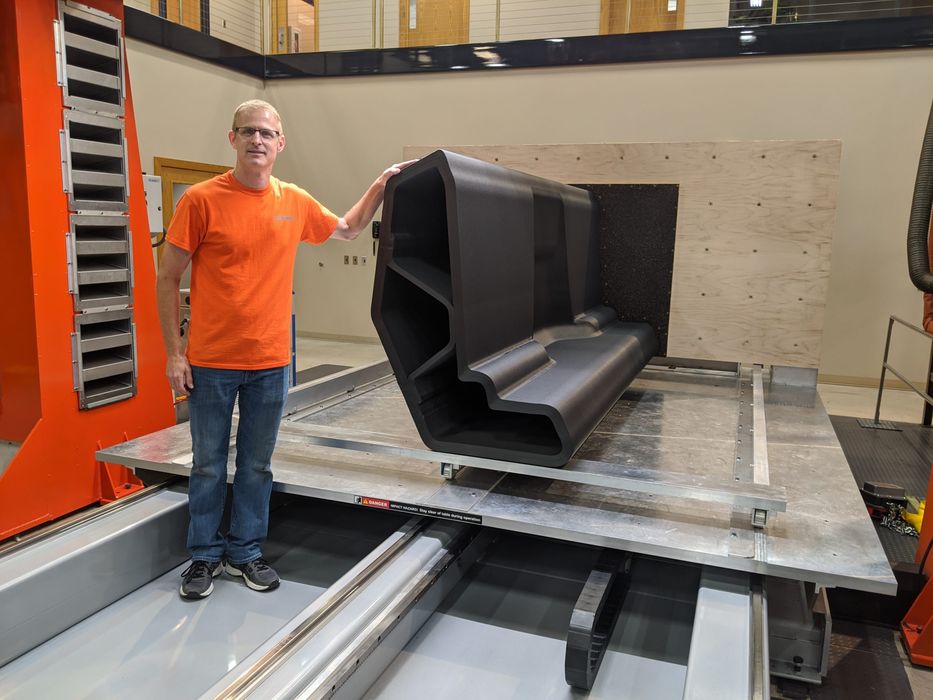

While woodworkers have long recognized Thermwood as a major player in CNC manufacturing, many probably don’t know the company is also a leader in large-scale additive manufacturing (LSAM). Thermwood routinely applies for patent protection on the additive manufacturing technology it develops for its LSAM large format additive systems, said Duane Marrett, Vice President of Marketing.

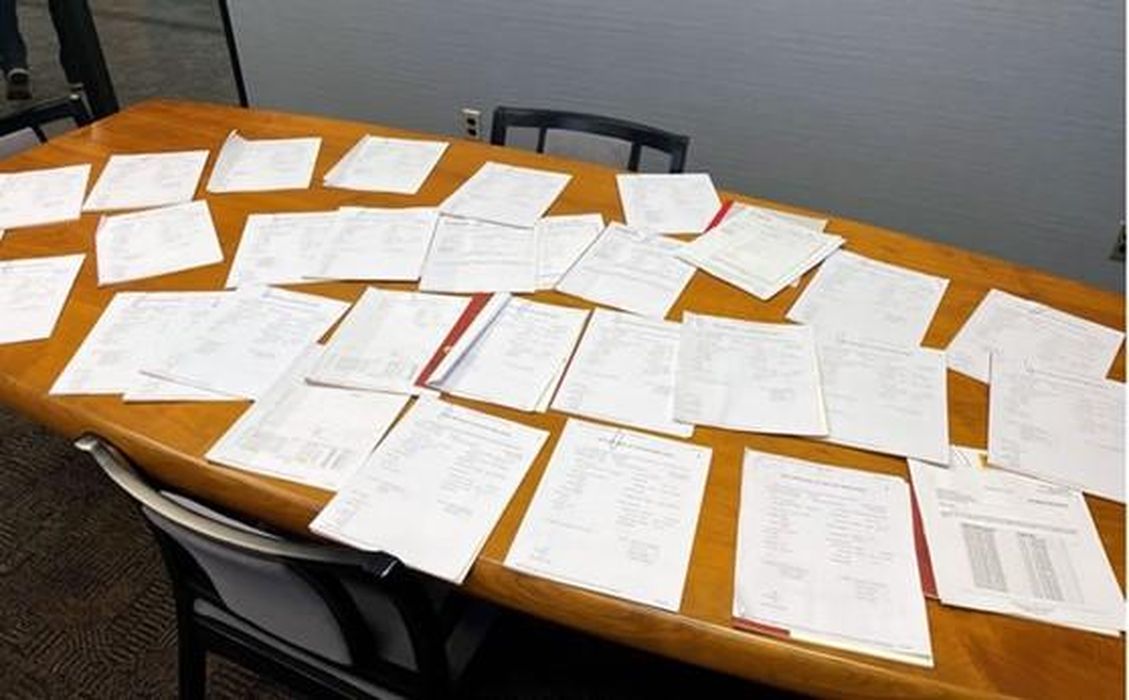

“During COVID, we received electronic copies of patents that were granted, however, the official hard copies were withheld,” Marrett said. “A couple of days before Christmas 2021, we received a package containing the official hard copy of 32 additive manufacturing patents. This was certainly a one-day record for Thermwood and a welcome sight!”

In addition to these latest patents, Thermwood already has a large portfolio of earlier issued patents covering the unique, large format (5×10 foot table and larger) 3D print technology it has developed. This LSAM technology is currently the most widely used large-scale additive print technology operating in the industry today, according to Marrett. LSAM is used across a variety of industries including aerospace, transportation, heavy equipment, foundries, and for large decorative structures.

“It is being used to produce a diversity of products including aerospace patterns, molds and tooling, heavy equipment foundry patterns, bus chassis, large valve body foundry patterns and trim tooling,” Marrett said. “It was even used to print the tallest 3D printed structure in the world – the 92-foot tall Al Davis Memorial Torch at Allegiant Stadium in Las Vegas.”

If you are used to desktop 3D printers that create small plastic objects, Thermwood’s machines offer something completely different.

“Thermwood offers this unique patented technology on a wide variety of equipment – the largest, most diverse product offering of its kind available today,” said Marrett. “It includes a broad selection of machines, including single and dual gantry, fixed and moving table configurations, with both print-only and print-and-trim systems, from 5-by-10-foot to 20-by-60-foot print envelopes. We are working on even larger machines but that’s for another day.”

Thermwood says they also offer the highest throughput print heads currently available with maximum print rates from 200 to more than 500 pounds per hour. The primary focus of the patented LSAM technology is to reliably and repeatedly produce high-quality, well-fused, homogeneous printed structures from reinforced thermoplastic polymer composites. This includes materials intended for use at elevated temperatures, Marrett explained.

“Although it is nice to have been granted these patents, it is even nicer to finally have the official hard copies in hand,” he said.

A Game-Changing Christmas Gift

Sometimes, unexpected good news around the holidays feels like an amazing holiday gift or miracle. That was likely the feeling at Thermwood when the team received the official hard copies of 32 newly granted additive manufacturing patents just before Christmas 2021.

The company regularly files patents for its large-format additive systems. However due to pandemic delays, Thermwood had previously only received electronic copies of these recently approved patents.

Seeing those official hard copies must have sparked immense pride – similar to the feeling a magazine editor has when holding the first physical copy of a publication they’ve worked on digitally for a long time.

Two years ago, Thermwood’s Vice President of Sales Dennis Palmer told 3D ADEPT Media that the company had over 55 patented features (and over a dozen more pending) for its LSAM technology. With the addition of these latest 32 patents, the total number granted now stands at 87 – making Thermwood the top patent holder in large format additive manufacturing/3D printing.

Patents ensure the protection of inventions like products, designs, or processes. They also signal the potential for commercial success. Thermwood is the developer of extra large format 3D printers and services using composite chopped fiber reinforced polymer (FPR) pellet materials. This enables the production of items used in aerospace, transportation, heavy equipment, foundries, and large decorative designs.

“Thermwood offers this unique patented technology on a wide variety of equipment – the largest, most diverse product offering available today,” the company stated. “It includes single and dual gantry systems, fixed and moving tables, print-only or print-and-trim, from 5×10 feet up to 20×60 footprint sizes. We are working on even larger machines for the future. Our primary focus is using these patents to reliably produce the highest quality printed structures possible across a range of reinforced thermoplastics, including high temperature materials. It’s fantastic to finally have the official patent documents in hand.”

Patent Picket Fencing Strategy

The large number of patents Thermwood has amassed points to the use of a “patent picket fencing” strategy. This involves filing patents for incremental improvements in order to fence competitors out of technology space. Fencing off specific areas can force rivals to license patents or explore costly workarounds to compete.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The breadth of patent coverage combined with the largest equipment offerings seems aimed at helping Thermwood dominate large-scale additive manufacturing using reinforced thermoplastics. The company may continue this patent strategy to maintain its first-mover and scale advantages as the industry grows. Delivering the hard copy gift of 32 more patents right before Christmas 2021 strengthened those competitive barriers heading into 2024 as well.