In the spring several 3D printer manufacturers set up “pop up” factories to rapidly produce PPE for the pandemic. But what happens afterwards?

This spring was a particular panicky state for the world, as the then-poorly understood novel coronavirus swept through many countries. The scenario was doubly bad because not only were medical facilities desperately short of required PPE, the normal supply chains were totally screwed up and deliveries from just-in-time traditional sources dried up.

Meanwhile, several 3D printer manufacturers suddenly found themselves the proud owners of unsold inventories of 3D printers. Their normal clients were a bit messed up due to circumstances, and purchases were delayed.

What were these 3D printer manufacturers to do?

Emergency 3D Printed PPE Factories

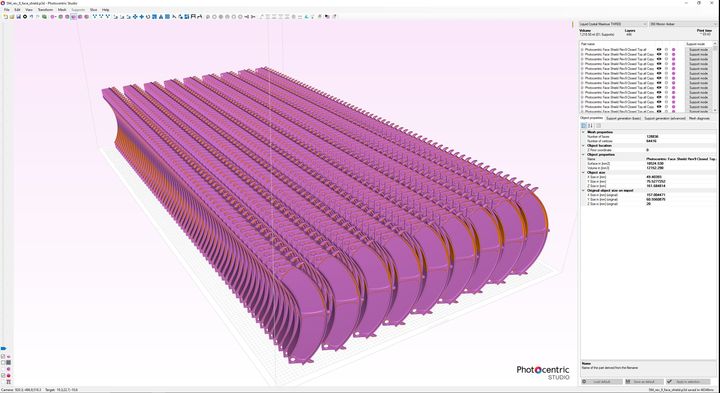

A few innovative companies came up with the idea of putting these otherwise idle machines to work producing PPE. Notable examples include UK-based Photocentric, US-based Formlabs and Canada-based Precision ADM, all of which quickly added massive production capacity for various forms of PPE and test swabs.

They may have saved the day for many, but these ventures also transformed manufacturing, where priority was no longer solely on efficiency, but now also included flexibility. And specifically, that meant regional manufacturing capabilities to overcome the risks of supply chain breakdown.

Since then many 3D printer manufacturers have reported record sales as companies seem to be at least experimenting with this novel concept.

But what about those emergency factories that were quickly set up in the spring? Do they need to exist anymore, particularly when the normal manufacturers have finally shifted gears and are producing the right goods in the right volumes?

I spoke with Photocentric’s Sally Tipping to find out what they are doing with their former PPE factory. Indeed, the first thing she told me was, “We’re moving on from face shield production.”

Does this mean they are shutting down their factory? Not at all: they intend to leverage it in an entirely different way.

Photocentric Factory

Photocentric is now targeting dental operations as clients for their large-scale resin 3D printers and will be using the former PPE factory to address that market.

They’ll do so in several different ways. First, they’ll use it as a demonstration center to show clients that it is possible to produce the items they require on the Photocentric equipment and with their materials.

Secondly, they will actually produce items for clients at the factory until the customers are confident they can produce them on their own.

Finally, the factory can also be used as a kind of overflow resource for clients that might receive a big order that exceeds their immediate capacity. These moves all can provide potential clients with a great deal of confidence with the solutions provided by Photocentric.

Tipping suggests they will eventually move into other industries with this concept, including things like automotive interiors or consumer products. I got the impression they were working with some unnamed software companies to help generate designs for highly complex objects, including “4D lattices”. These would again help persuade clients of the benefits of using their solutions.

One approach they’re testing is the use of textured surfaces on 3D printed parts. The idea is to hide the normally slightly visible layer lines with textures to allow for more “familiar” appearing parts with clients. This method could enable skeptical prospects to change their minds about the technology when shown at a demonstration center.

Photocentric Expansion

To achieve all this Photocentric will have to expand, and that’s also in their plans.

They intend on setting up more of these 3D print farms based on the success they’ve seen so far. Currently, their plan is to set up one in Europe and another in North America, but these have not yet opened.

It’s startling to realize that perhaps none of this would have occurred had it not been for the global pandemic, which forced Photocentric and others into a very different situation. Now, their path to the future seems a lot clearer.

Via Photocentric