I had a chat with XJET’s Dror Danai about the company’s strategy.

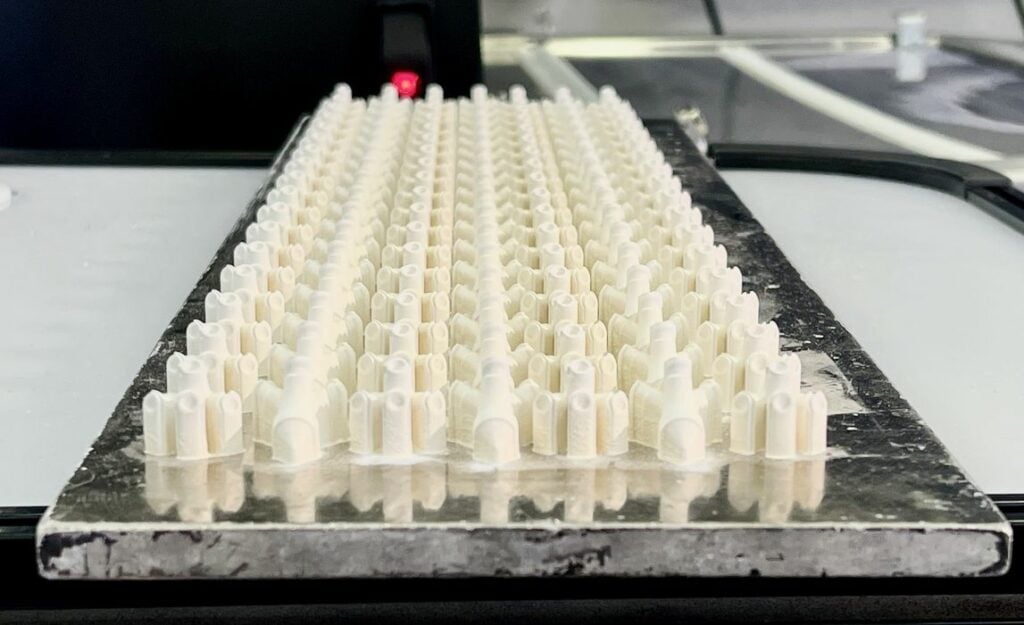

XJET is an Israeli company that emerged only a few years ago. They developed a highly unusual 3D printing process they call “NanoParticle Jetting”, or NPJ. It involves selectively depositing tiny liquid droplets containing solid nanoparticles of material in suspension. As the print proceeds, the liquid is removed, leaving the particles arranged in the desired geometry. The process is quite flexible, and can theoretically be used to build in a wide variety of materials. So far, XJET has only produced metal and ceramic versions.

Danai, XJET’s Chief Business Officer, explained that the company has undergone a bit of a transformation during the pandemic, when many 3D printer manufacturers suffered drops in sales. XJET was in a rather different position, as they were just on the verge of perfecting their solutions.

Having had limited installations in multiple locations, they had been able to gain valuable feedback on their equipment, materials and processes, allowing them to tune up their systems. Danai explained:

“It gave us time to stabilize the technology. Now you can turn it on in the morning, and it drives all day.”

As an example, Danai explained the company spent time working on their alumina ceramic, which they “perfected during COVID”, and it went commercial at the end of 2020.

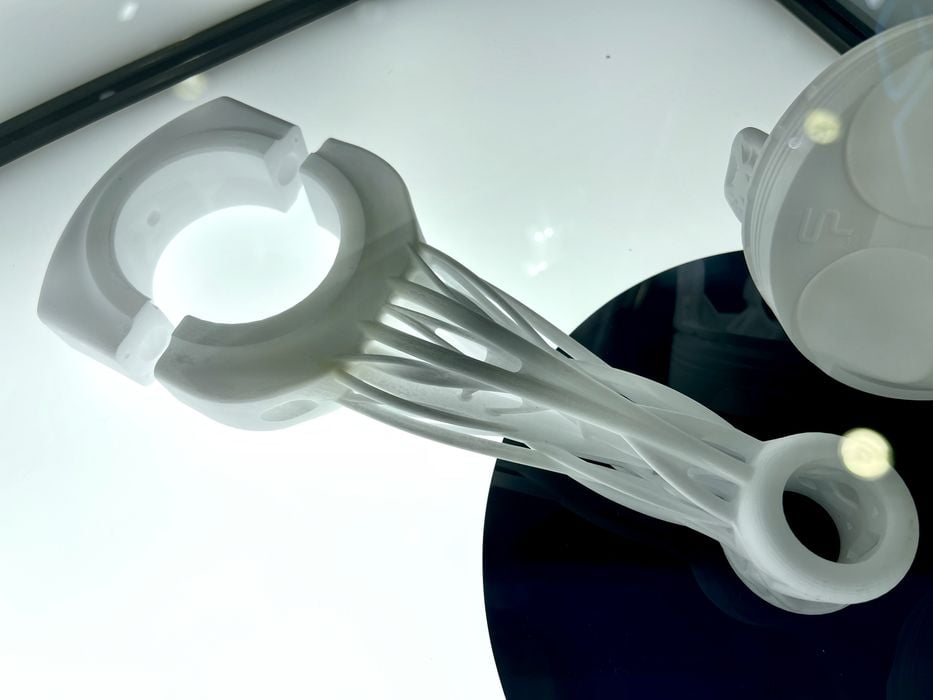

One fascinating example of XJET’s ceramic capability is a high-performance ceramic piston for a supercar engine, shown here. This design clearly demonstrated that their powerful ceramic technology can be used for extreme production parts.

Danai related an experience with a client that was seeking the ability to produce metal objects of particular geometries at high levels of quality. The client sent XJET ten different files to test, and XJET was able to successfully produce eight of the ten of them to the client’s satisfaction. Later, XJET learned that they were the only company able to produce any of the ten models.

Danai said they signed a deal with the company “in hours”.

XJET is now moving into full commercialization of their technology, having stabilized the product. This is par for the course for a successful startup: first get the product working and prove its value with initial clients; then greatly expand operations with emphasis on sales and distribution, with less emphasis on technology development. That seems to be where XJET is at the moment.

Danai reports XJET grew to over 100 staff in recent months, an increase of more than 25%. A big part of that increase is their increased focus on the US market, where they’ve been hiring engineering and sales personnel.

Danai told us:

“Covid allowed us to be ready for the mainstream market.”

And so they are.

Via XJET