Many startups do a “pivot” early in their lifecycle, and Primax is no exception.

The German startup company is quite young, having been founded only in April 2017, not even a year ago, but now faces a change that could lead to very big things in the future.

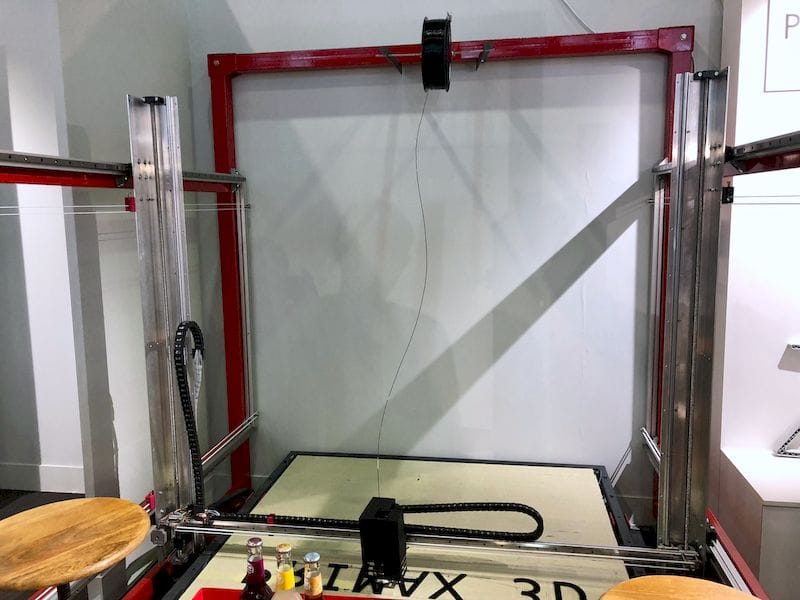

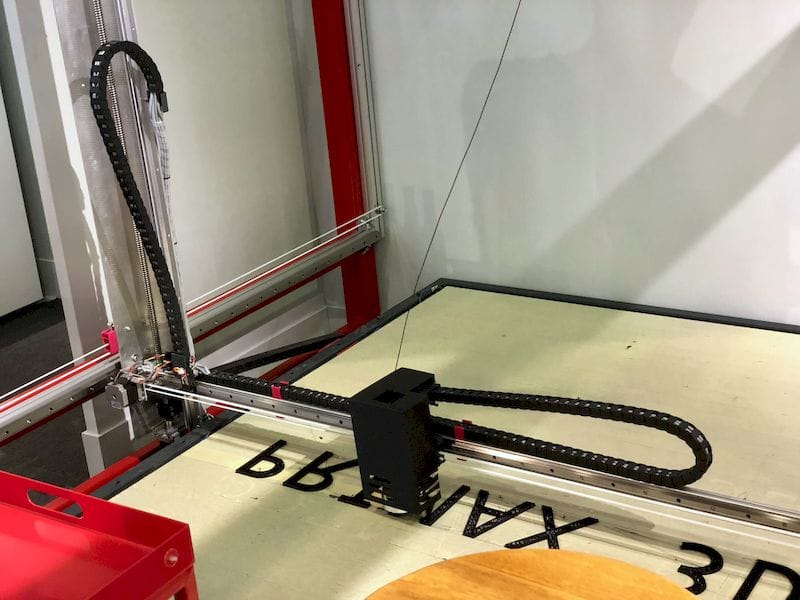

They began as a kind of 3D print service; the founders were able to construct a rather large 3D printer. How large? The build volume on their unnamed 3D printer is an incredible 3000 x 3000 x 1500mm. That’s 3 x 3 x 1.5m!

The machine includes a heated build plate, a necessity for ANY thermoplastic at that size, but the machine does not include an enclosure. Thus it is able to print only low-warp thermoplastics such as PLA. They’ve also devised their own filament that works very well with this machine.

After building the machine they began to accept orders for one-off large prints. They 3D printed full automobile bumpers, presentation stands, propellors, frames for concrete pours, and similar large objects for local companies.

However, something has changed. While they are operating as a 3D print service, it seems that at least a few of their clients are asking if they can BUY one of the machines.

This is a transformative decision for the small company. While you might think it’s a straightforward decision, there are a lot of advantages and disadvantages to consider.

On the positive side, transforming from a service business to a printer manufacturer could be very profitable. Instead of selling prints worth hundreds or thousands, you could be selling printers worth tens of thousands.

On the negative side, creating a manufacturing process capable of delivering high quality machines is a daunting task. It’s one matter to ad-hoc construct a single machine and operate it yourself and quite another to reliably – and cheaply – build many machines that are to be operated by other people. To gain that capability they’d likely have to hire manufacturing expertise and possibly outsource production. It would require considerable investment.

It may also compromise their 3D print services business, as the most likely buyers would be those who are currently spending a lot of money buying prints from them. It could be a one-way decision.

But that may be a good transformation, in spite of the challenges, simply because the large-format 3D printing market is one that is definitely proven, with several parties marketing devices of such scale. Each of them seems quite successful and profitable, so there’s little reason Primax3D couldn’t be another one if they execute properly.

It’s not clear whether Primax3D will pursue this approach, but whatever their decision, we wish them well!