There are several large-format 3D printers available today, but none seem to be able to do what the Kong3D does.

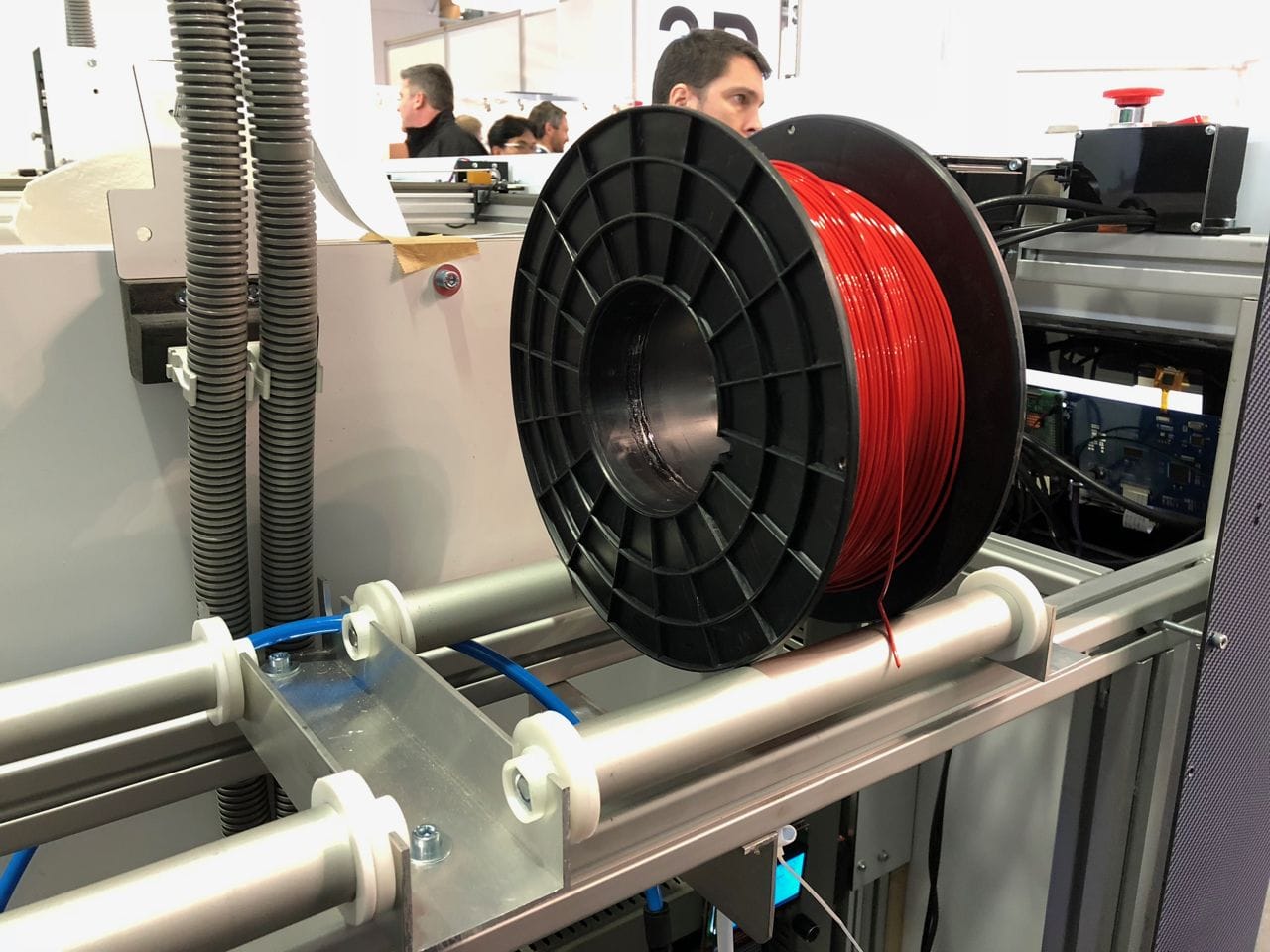

Berlin-based 3BOTS 3D Engineering GmbH is the producer of the Kong3D, one of the largest volume plastic extrusion 3D printers one can find these days. The company launched their Kong3D earlier this year, although you can’t quite order the product yet. We were told the Kong3D is “close to version 1.0”. Availability is set for first quarter 2018, although they do apparently have a couple of beta testers running now.

Unlike some large format 3D printers, the Kong3D is slightly enclosed, whereas others are fully open to ambient air conditions. They say it’s “three quarters” enclosed, meaning there are panels on three of the four sides of the machine. These panels are attached with magnets, allowing very easy temporary removal after a print finishes. This permits more accessible methods of removing the very large prints that will emerge from this device.

The machine will print PLA and PETG filaments, and even some flexible materials. Although the hot end is able to hit a warm 250C, I would not recommend attempting printing of ABS or other <$wc> materials, as they would simply lift off the 70C heated bed at the size you’ll be printing with the Kong3D.

One interesting feature is the air cooling system, which is not simply a fan as appears on most 3D printers. Instead, the Kong3D uses a high pressure air system to deliver good quality cooled air directly to the print and extrusion system. This should help with print quality, as the freshly extruded material will freeze very quickly upon extrusion.

But that’s definitely not the most interesting feature of the Kong3D. This machine can 3D print (almost) without the use of support structures!

You might be wondering how this is accomplished, given its appearance: it looks like any other desktop 3D printer, with three axes and a moving hot end. It is curious, however, that their build plate can move up and down on the Z-axis, unlike many other large format 3D printers in which the hot end moves in X, Y and Z. There is an important reason for this.

The surprise is that the print plate can tilt! Evidently 3BOTS designed the Kong3D’s print plate to swivel up to 30 degrees during printing operations.

But how does this affect support structures? Their software detects overhangs in the 3D model and then coordinates the movement of the print plate and hot end to reduce the effective overhang angle at the moment of extrusion. Essentially, it tips the print just the right amount to reduce the overhang.

And this should work very well. It’s known that overhangs of 45 degrees or even more are easily handled by most extrusion 3D printers. I often set my overhang threshold at 60 degrees and have few if any issues. Now consider this: if the Kong3D can tilt up to 30 degrees, then the maximum extrusion angle would be 90 degrees minus 30 degrees equals 60 degrees. That’s something the can be printed.

And indeed, 3BOTS showed off some prints that had apparently undergone this process and there were no support structures visible.

Eliminating support structures is a big deal, as it can be a huge manual effort to remove them after printing, particularly on the large prints that would come out of the Kong3D. The surface quality will be much better, and you’ll use less material.

There is one challenge with this approach, however: the build plate’s Z mechanism must be able to lift (and tilt) potentially large and heavy prints. This may be a limitation in how big your objects can be, but 3BOTS has not indicated anything of this nature.

All this means is that the Kong3D is likely to be a good device to 3D print very large hollow objects, perhaps for advertising purposes.

3BOTS informs us that the price of the system will be in the €30,000 range (USD$35,000).

Via 3BOTS