Michigan Tech’s Open Sustainability Technology Lab, or “MOST”, announced an open source, high-temperature 3D printer.

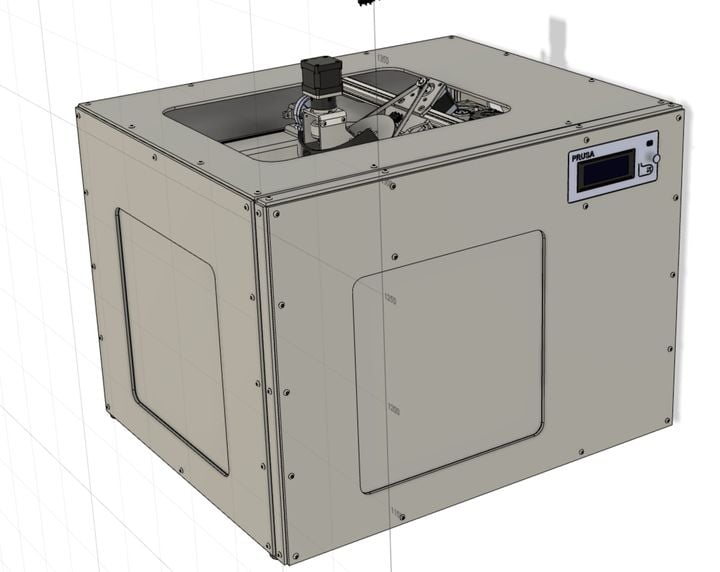

Cerberus High-Temperature 3D Printer

The “Cerberus” is the device in question, and it is perhaps the first high-temperature open source 3D printer, with its specifications and files free to use by the public. The device is built RepRap-style, meaning it can produce many of its own components itself, a form of partial self-replication.

High-temperature 3D printers are considered useful because they are able to handle materials with much higher temperature resistance. Of course, to soften these materials for extrusion you require an even hotter 3D printer, and that’s what this project is all about.

The Cerberus is said to be buildable for under US$1,000, which is fantastically lower than all commercial high-temperature 3D printers, which typically are priced above US$10,000 or much more.

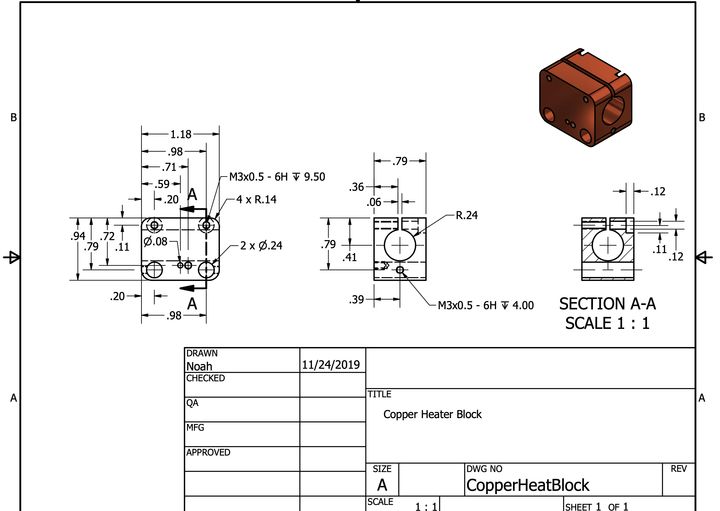

For that price and some assembly know-how, you may be able to construct a 3D printer that has a 200C heated print surface, a 500C hot end, and a fully heated build chamber that uses a 1kW heater core.

This configuration has been shown to enable successfully 3D printing of PEEK, PEKK, ULTEM and other commonly used high-temperature 3D printer filament materials.

Cerberus Pellets

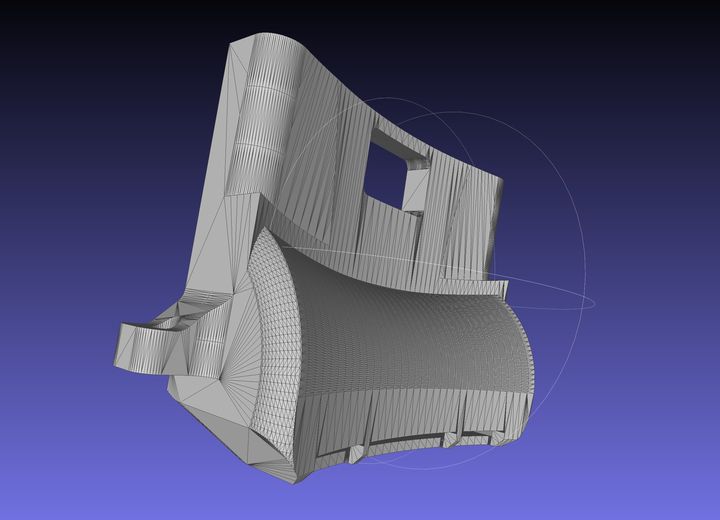

One interesting feature that seems to be in the repository is a pellet extruder. If this truly works, then it would free the high-temperature 3D printer operator from buying expensive filaments and instead they could purchase cheap pallets of thermoplastic pellets. This could make production on the Cerberus quite inexpensive.

I should point out that building the Cerberus is not for anyone. While the complete set of plans, including documentation, software, STL files, drawings, etc., are provided, it will require someone with considerable machine-making skills to put it all together.

High-Temperature 3D Printing And COVID-19

One reason for releasing open source plans for this device is in fact a direct way to help with COVID-19 efforts. Because the Cerberus is able to 3D print objects with high temperature resistance, it also means the printed objects can be easily sterilized in a variety of ways by medical facilities. Objects made in PLA or ABS, for example, might wilt under the heat of certain types of sterilization equipment.

In other words, if one could equip a hospital with this type of device, they could produce small quantities of needed sterilizable parts on demand. The Cerberus aligns nicely with the notion of having every hospital have its own makerspace in which to quickly build emergency parts.

Open Source High-Temperature 3D Printer Competition

There’s another interesting implication: since these plans are now open source, someone, anywhere, could easily use them to launch a commercial business selling easier-to-build kits. That is in fact the business model pursued by Prusa Research, and since then they have grown immensely and now offer many 3D printer models.

A commercial company using the open source Cerberus design could theoretically offer a very low-cost high-temperature 3D printer to the public, and that could cut into the markets that have been quite profitable for the few manufacturers of high-temperature 3D printers.

That could be bad news for some of these manufacturers, but good news for those seeking high-temperature 3D printing equipment at lower prices. It’s likely the current high pricing of this equipment has prevented some from using the technology, but perhaps now that will no longer be a barrier.

Via Science Direct and OSF