We tested samples of several filaments from Verbatim, who have recently entered the market for 3D printer supplies, and were very impressed with the results.

As we reported previously, Verbatim enters the market with a good selection of high-quality 3D printer filaments, all based on patented plastic formulas from their parent company, Mitsubishi. We expected good results and indeed that was the case.

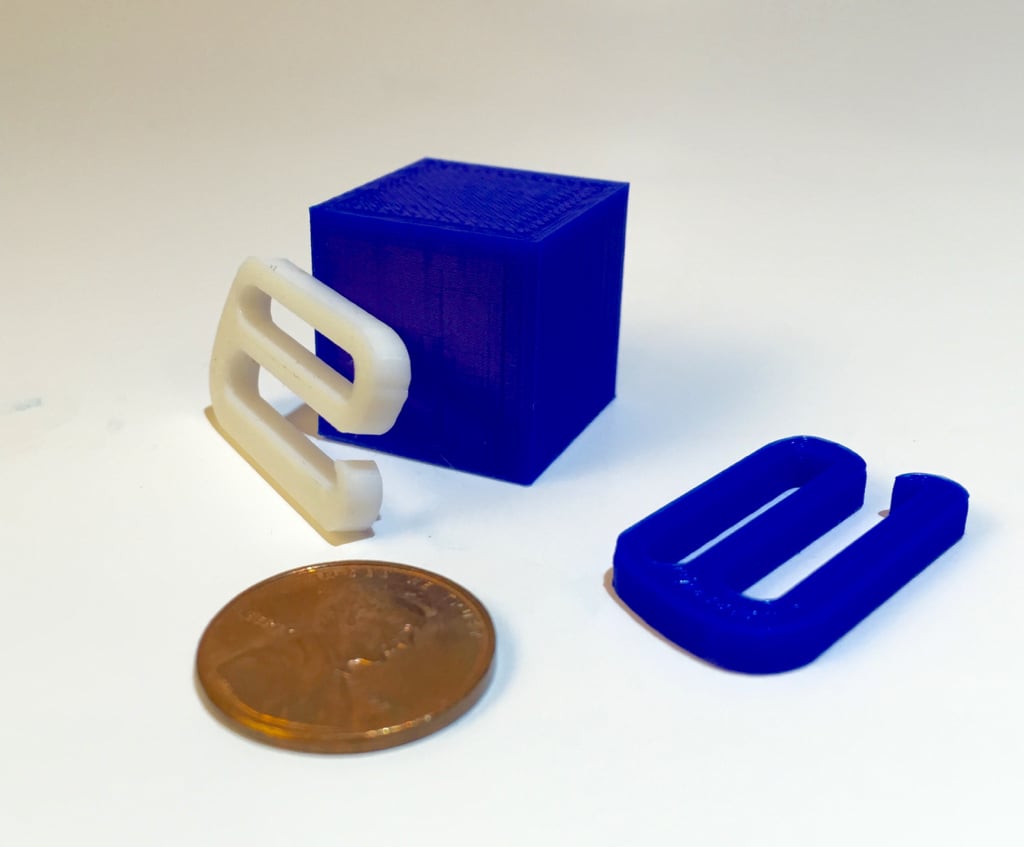

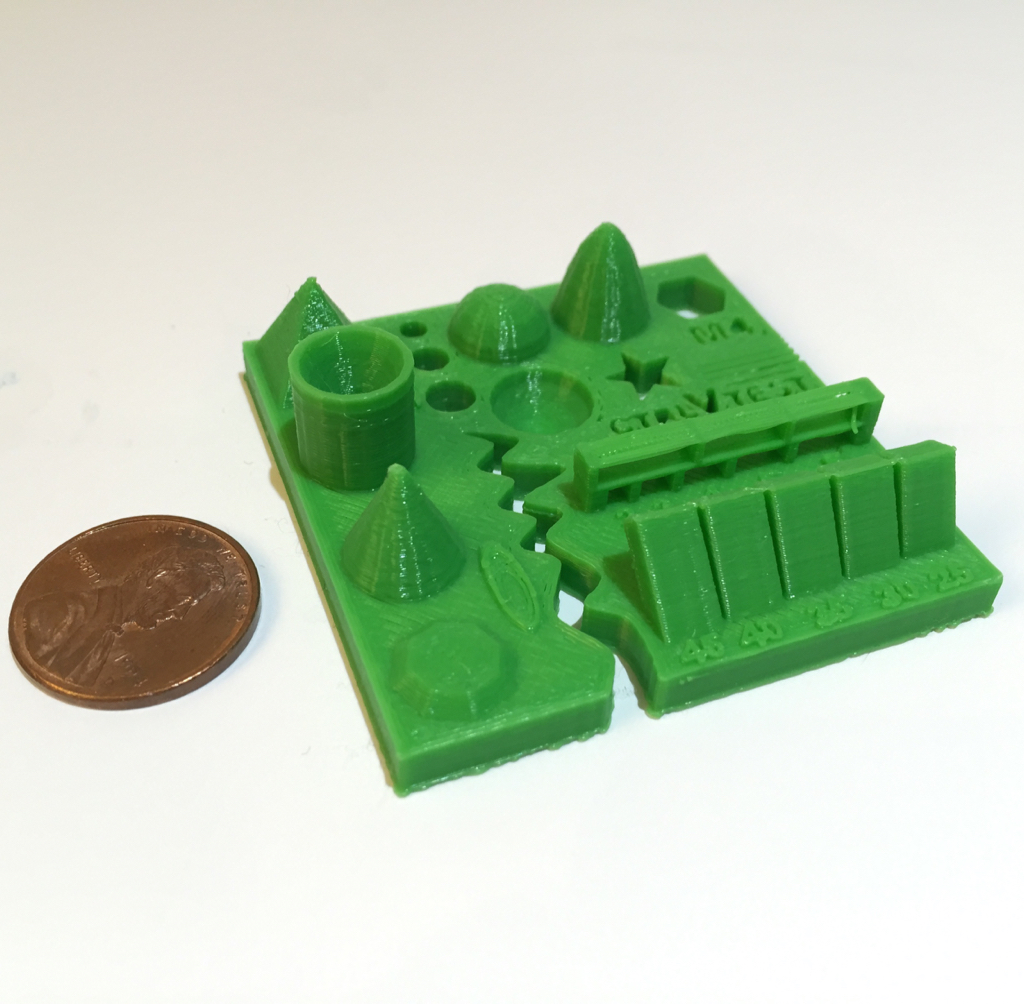

Here we see the popular Control-V test object, successfully 3D printed in PLA. It came out near perfectly, with no errors visible.

Similarly the #3DBenchy test also performed very well, although there were very slight issues on the overhangs, but that’s where most plastic extrusion 3D printers fail regardless of the filament.

The important thing is that we experienced no jams, pops or inconsistencies in the filament during testing. The Verbatim PLA filament is clearly high-quality and we would not hesitate to use it in the future, particularly if you require large quantities of consistently colored filament.

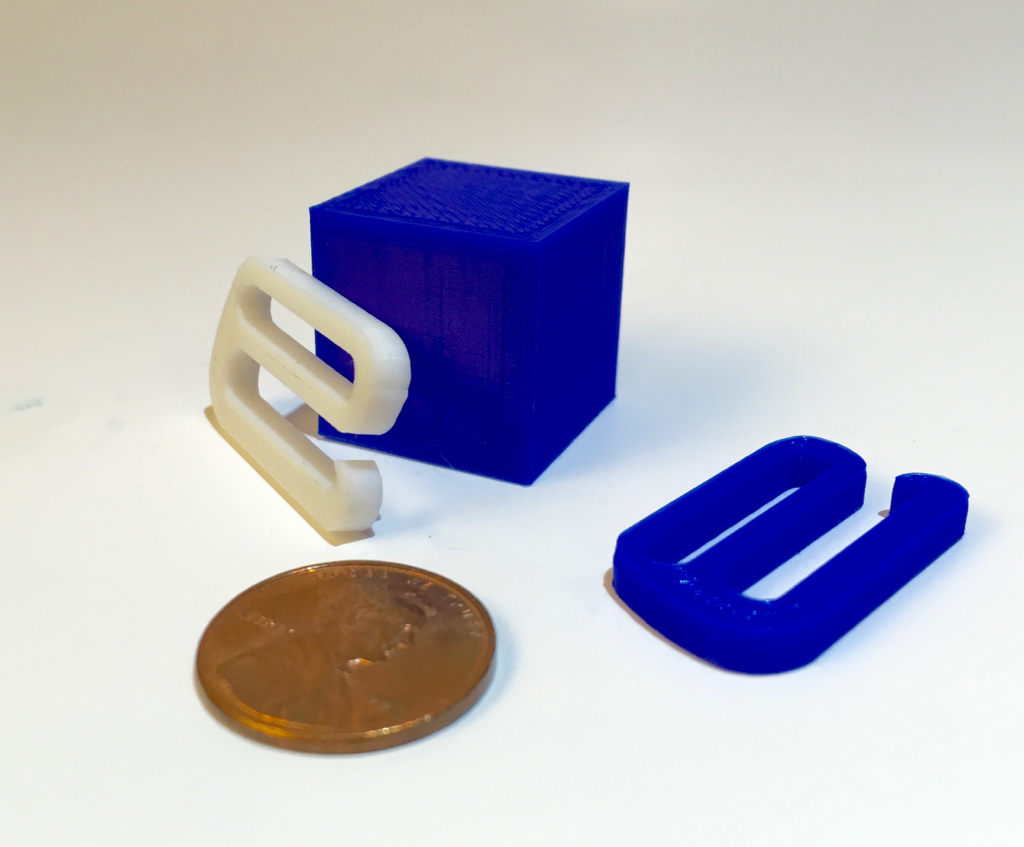

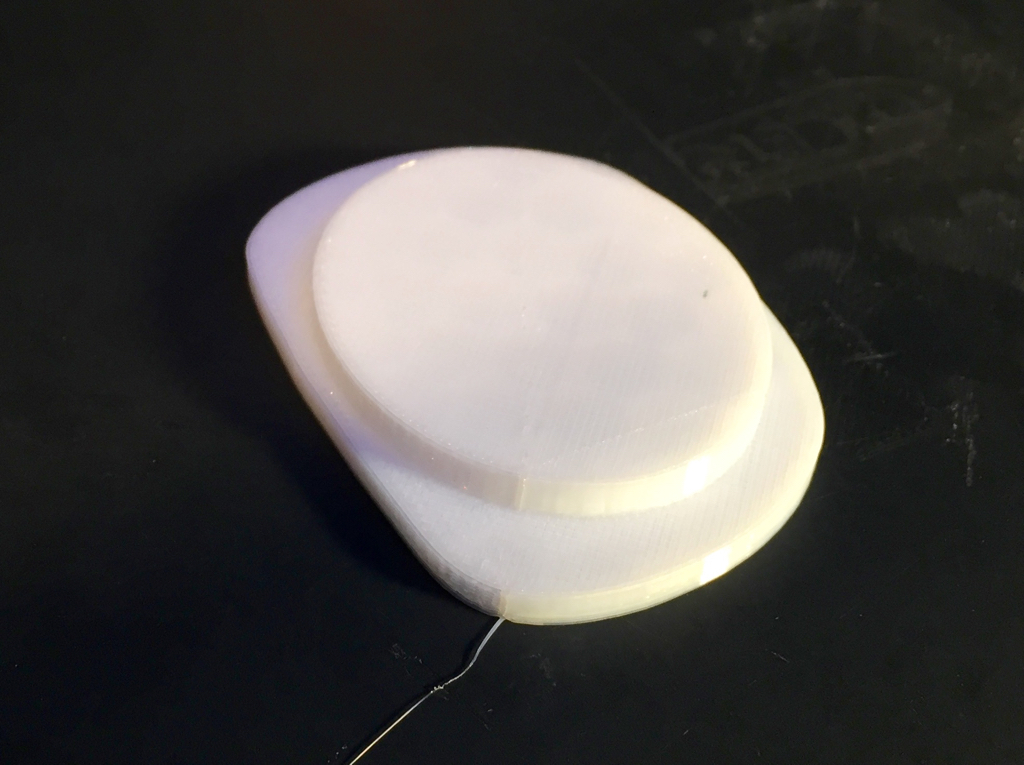

We also were able to test a small amount of Verbatim’s unusual “Primalloy” material. This is a flexible substance that can be printed on almost any personal 3D printer, so long as you slow the print speed. Our testing at 25mm/second yielded no problems. No jams occurred at all, something that happens frequently with other flexible filaments. Here we see a plug printed in Primalloy, which should work perfectly once we print the rest of the object in standard rigid material.

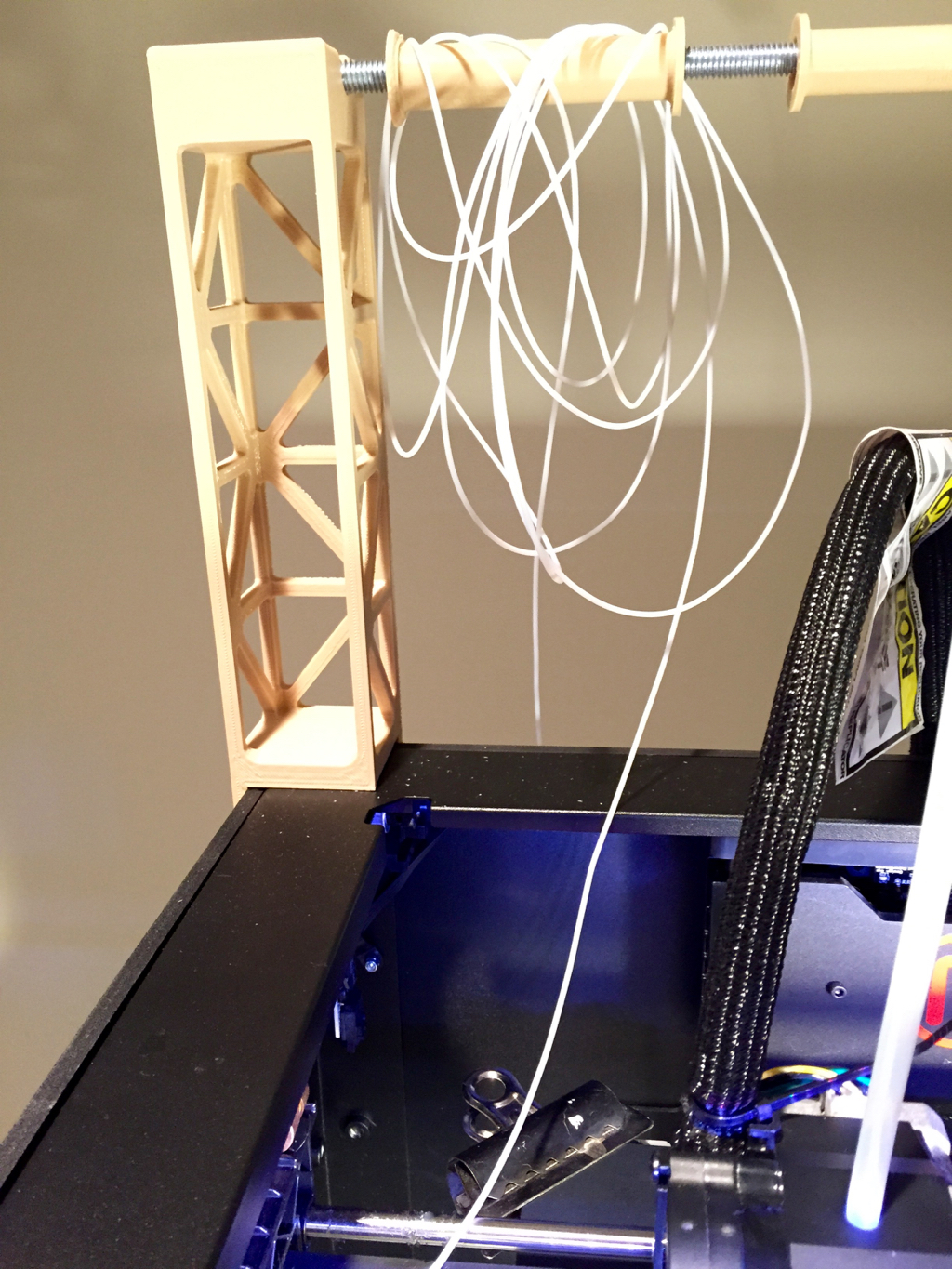

Primalloy has some interesting operational characteristics. While it is sold by spool, our sample was a small unspooled coil. It turned out to be inappropriate to hang the coil on our filament rack, as the extreme flexiness of Primalloy quickly tangled up the coil: there is no rigidity to cause the coil to rotate around an axis! We found the best way to print a coil was to simply drop it in a pile on the table, and the slippery, spaghetti-like substance sorted itself out easily.

Another issue with hanging a coil is that the loose end can (and WILL) flop over into the active printer build volume, which is of course not a good idea at all.

For adhesion, we found Primalloy to stick perfectly well to our flexible PRINTinZ plate. However, since the print is flexible, the usual method of removal from the plate (flexing it), was entirely ineffective. Instead, you must trowel the Primalloy print off the plate, and you won’t hear any satisfying “cracking” sounds – it just silently peels away like a snail on the counter.

Another interesting fact about Primalloy is that it is almost odorless during printing, unlike pungent ABS or sugary PLA.

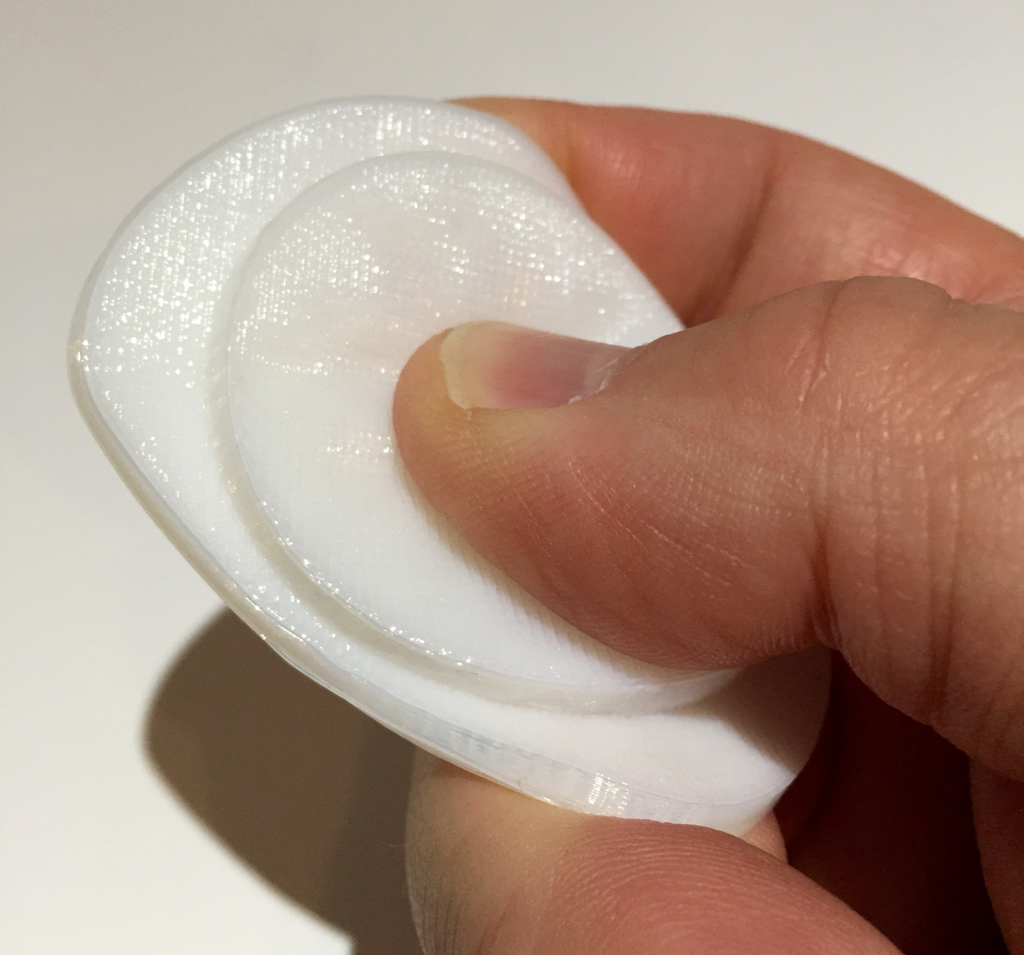

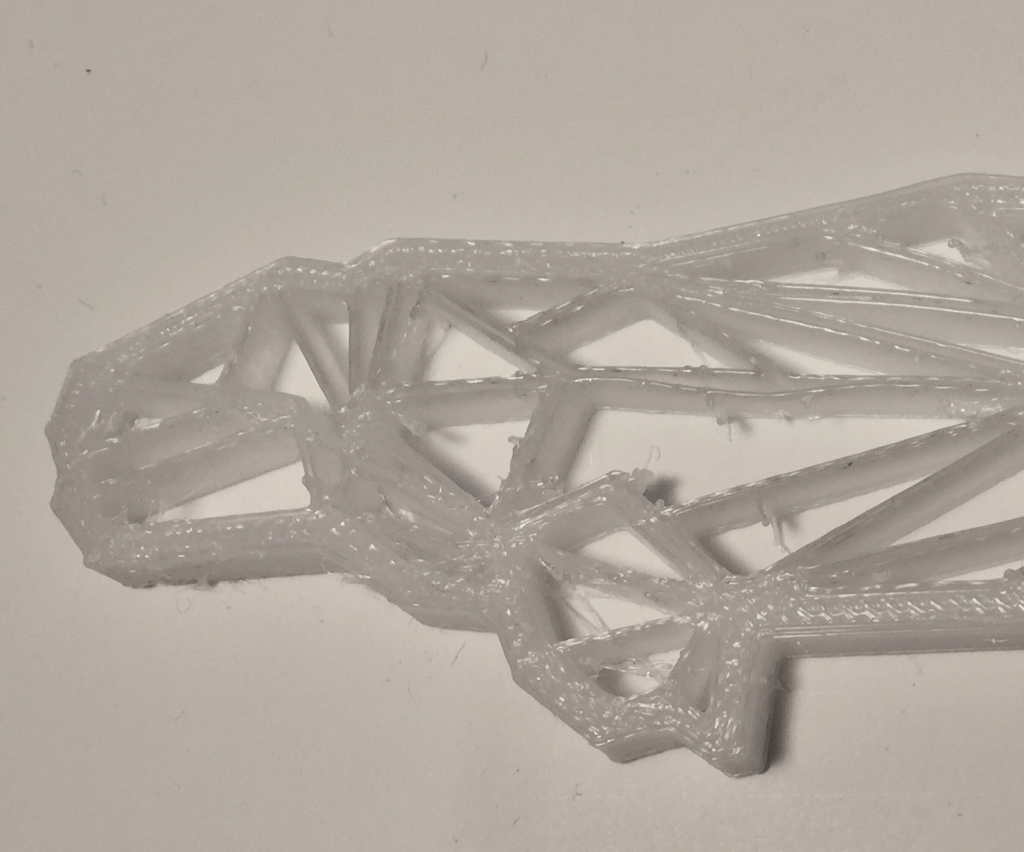

The material tends to stretch more than typical rigid plastics, as you might expect. Depending on the geometry of your 3D model, you might encounter additional stringies between extruder movement points, as seen here in this squishy Beluga whale 3D print by artist Kal Barteski.

Aside from the stringies, Primalloy is a wonderful material to print with. If you have a need for printing flexible items, you definitely should look into Verbatim’s Primalloy, which currently costs USD$88 per 500g and is only available in white color. Yes, it’s expensive, but is definitely worth the cost.

Via Verbatim