Monocolor 3D prints are so dull-looking; that’s why many people paint or finish them. But what if you could do so with the world’s darkest material?

Vantablack is an incredible substance, made by Surrey Nanosystems of the UK. This nearly unbelievable material is truly incredible, as it absorbs 99.965% of light falling on it. In other words, it’s the blackest thing you’ve ever seen.

I recently saw an example of this at the London Science Museum, where a small mask had been coated with Vantablack.

The image above does not really do this justice, as it is so deeply dark that it reflects nothing. You cannot visually detect any texture whatsoever. You cannot see any shadows to reveal contours.

It looks like a “hole” in space before your eyes. The image at top is exactly what you see. Or don’t, in reality.

Here I attempted to get a closeup of the sample, but as you can see, I was unable to focus on it properly. Why? Because it doesn’t reflect anything, even the infrared focusing beam!

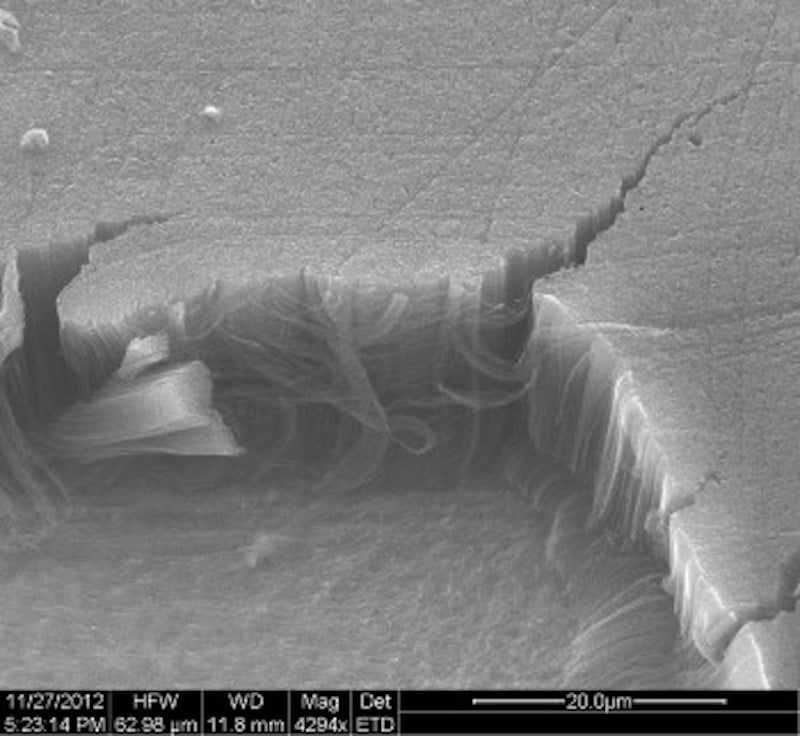

So how does this magic material work? It turns out it’s a dense forest of carbon nanotubes.

Here we see a microscopic image of Vantablack, where you have very tall and thin nanotubes rising like a field of grain.

This is how it works: light beams enter the “forest” and become trapped, endlessly bouncing between the nanotubes, eventually becoming a tiny bit of heat.

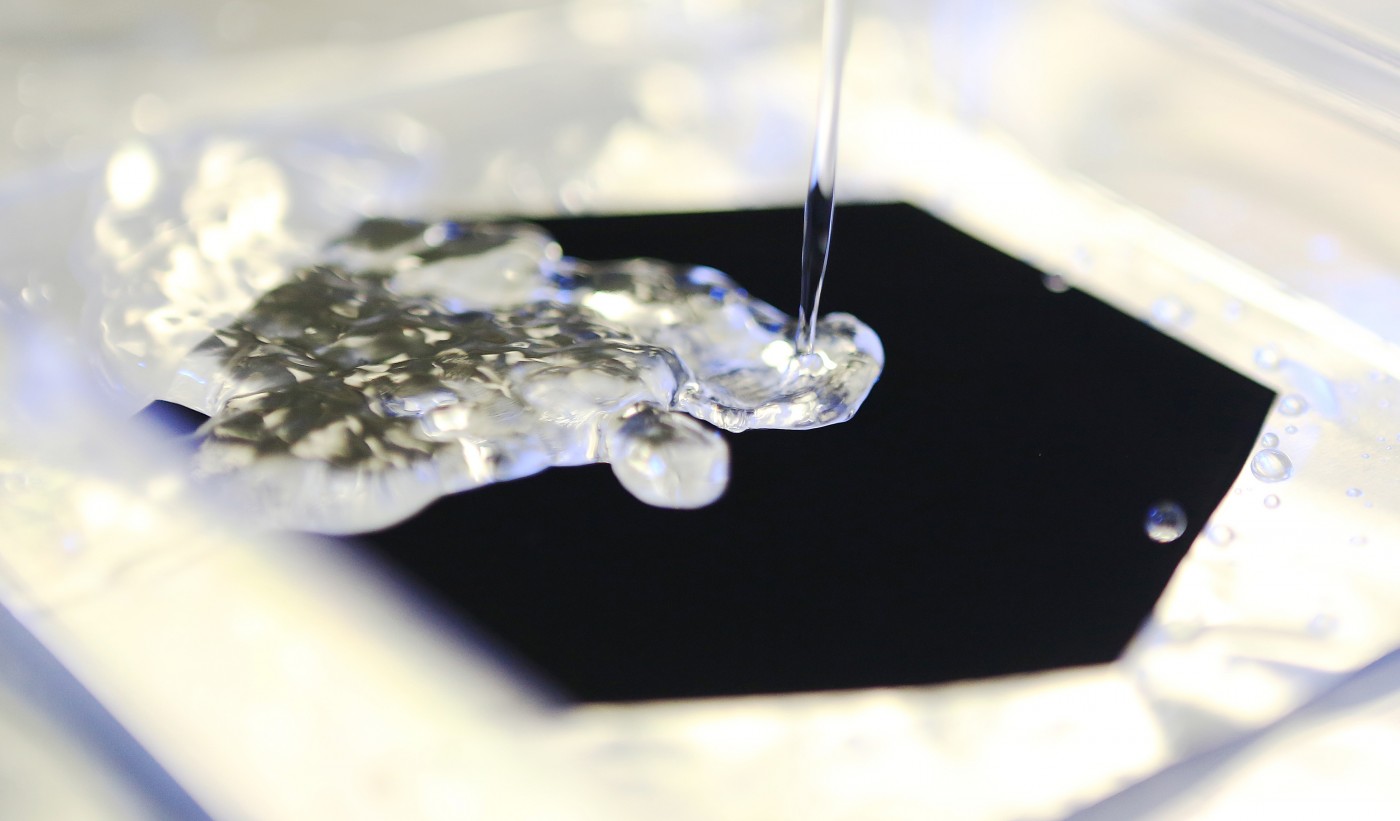

Vantablack also has other properties aside from being literally invisible; it repels water perfectly, as water cannot penetrate the nanotube forest.

Now, wouldn’t it be terrific if we could apply Vantablack to our 3D prints? Making invisible objects? Can we pick up a spray can of Vantablack at the local hardware store?

Apparently not. It turns out that the application process for Vantablack is a highly complex industrial process requiring precision equipment.

And there’s something else: it requires 450C temperatures. This means that any object having Vantablack applied must be able to withstand that temperature. For typical plastic prints, this rules out the possibility of Vantablack application.

However, metal 3D prints could definitely be Vantablack-ized. Surrey Nanosystems says they’ve already been able to apply the wonder substance to:

- aluminium sheet/foil, aluminium oxide, aluminium nitride

- aluminium alloys (6000, 7000 series)

- cobalt

- copper

- molybdenum

- nickel

- quartz

- sapphire

- silicon, silicon dioxide

- stainless steel

- titanium, titanium nitride

So it would not be unreasonable to attempt this process on metal 3D prints – or metal cast 3D prints. Just forget about it for plastic.

Oh, and did I mention that the cost of Vantablack probably exceeds coating your object in solid gold?

Via Wikipedia and Surrey Nanosystems