There’s a very strange announcement on the BAE Systems site, proposing a “chemputer” that would “grow” objects. Is this something that’s actually feasible?

BAE Systems specializes in developing military and intelligence equipment, and apparently they’ve been doing some thinking about how to dynamically create weapons systems. Here’s how they explain the concept:

A radical new machine called a Chemputer™ could enable advanced chemical processes to grow aircraft and some of their complex electronic systems, conceivably from a molecular level upwards. This unique UK technology could use environmentally sustainable materials and support military operations where a multitude of small UAVs with a combination of technologies serving a specific purpose might be needed quickly. It could also be used to produce multi-functional parts for large manned aircraft.

Ok. That doesn’t really tell me how this works. Perhaps their video does?

That’s certainly interesting, but I’m still at a loss to understand how this works.

In a way, this is similar to 3D printing: molecules of material are placed in precise positions to build up an object in an additive manner. The difference is that today’s 3D printing is placing zillions of molecules at the same time (and usually the same kind of molecule), whereas the “chemputer” concept would involve placement of individual molecules (or at least a very much smaller quantity than current tech).

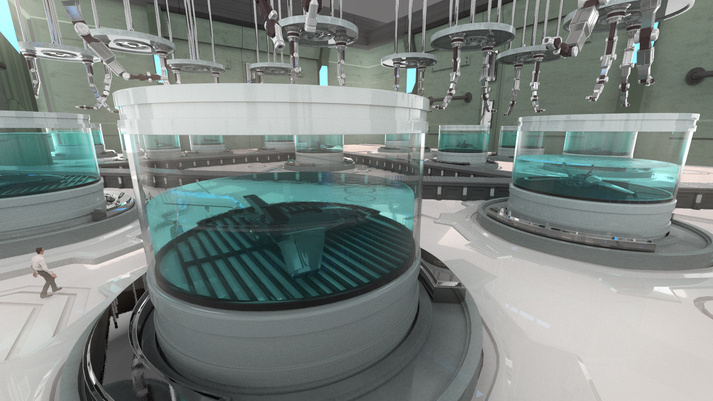

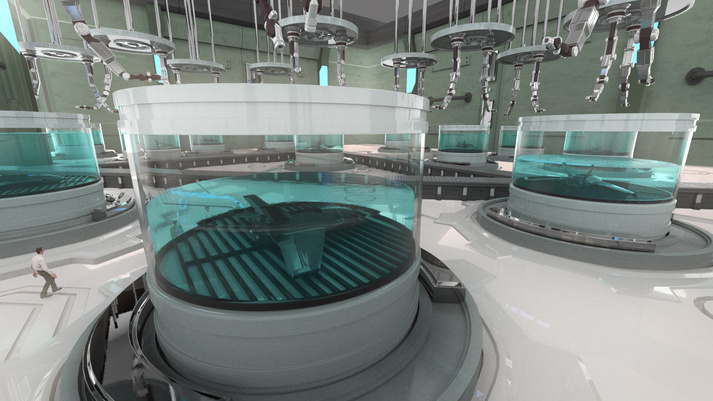

The “chemputer” is also reminiscent of proposed nanotechnology capabilities from years ago, in which nano machines would assemble a complete object, molecule by molecule in a tank filled with dissolved raw materials.

Is this concept feasible? I see the major challenge being how to direct the placement of molecules to precision locations and coordinate building. For example, if you’re building (or “growing”) section “A”, when do you stop? How do you prevent multiple assemblers from simultaneously attempting to place molecules in the same spot? How is the overall plan communicated to the system?

This would all be much easier if the object was made from a single material, but for any truly functioning object, you’d most likely require a large array of different materials to comprise the subsystems of the intended design.

This sounds extremely difficult to achieve.

So is it possible? Perhaps with new technologies that overcome the major challenges, but certainly not today.

If it were indeed possible to do this, then the idea of using it to build drones seems rather nearsighted, as you would have literally built a “Star Trek” replicator, capable of building many kinds of functional objects. Such technology would rapidly be deployed as local (or even personal) factories, where any objects would be delivered electronically through transmission of the designs and use of local molecules for building material.

In any case, this is very far off into the future. But certainly very interesting and inspiring. Good luck, BAE Systems!

Via BAE Systems