The truth with a desktop 3D printer is that you will definitely be performing service on it. But there’s one easy technique you must master.

The “cold pull” technique is one that I found long ago and have used on many different 3D printers with great success. It’s a method of clearing the extruder of debris.

But why is there debris? It turns out debris is inevitable for several reasons on filament-based plastic extrusion 3D printers:

- Overheated hot ends burn small amounts of plastic which accumulates on the inside of the nozzle

- Contamination of foreign particles within the filament itself, direct from the manufacturer

- Accumulation of burnt dust that’s been falling on an enshrouded filament spool

- Accidentally dropping junk into the hot end

- Other other scenarios

However it happens, you’ll notice. Typically you’ll encounter an under-extrusion, where insufficient material seems to be coming out of the extruder for no apparent reason. If the extruder is pushing the filament and the spool is rotating freely, there’s only one other possibility: there’s a blockage in the hot end.

The hot end is a kind of trap, where the tube leading to the nozzle is larger than the hot end. Thus, stuff that fits into the tube, typically 1.75mm, might not fit through the nozzle opening, which is usually 0.4mm wide.

You might initially think the solution would be to remove the hot end nozzle and “clean it out”, but that’s sometimes difficult if you have plastic in it. And how, exactly, do you “clean it out”? If you are holding a blocked nozzle in your hand it probably isn’t going to be easy to clear unless it’s heated to allow the plastic to flow.

Another thought might be to poke a needle up the nozzle to clear things. But that’s not a great idea for a couple of reasons. First, poking anything up the (probably soft brass) nozzle may result in deforming the hole! It may be suddenly bigger than expected, making printing far more difficult because your slicing program won’t know how much material to properly extrude.

Secondly, if you push a chunk up the nozzle, it will just come back down later and clog again.

The answer to all this is the cold pull technique, which is actually easier to do than all of the above.

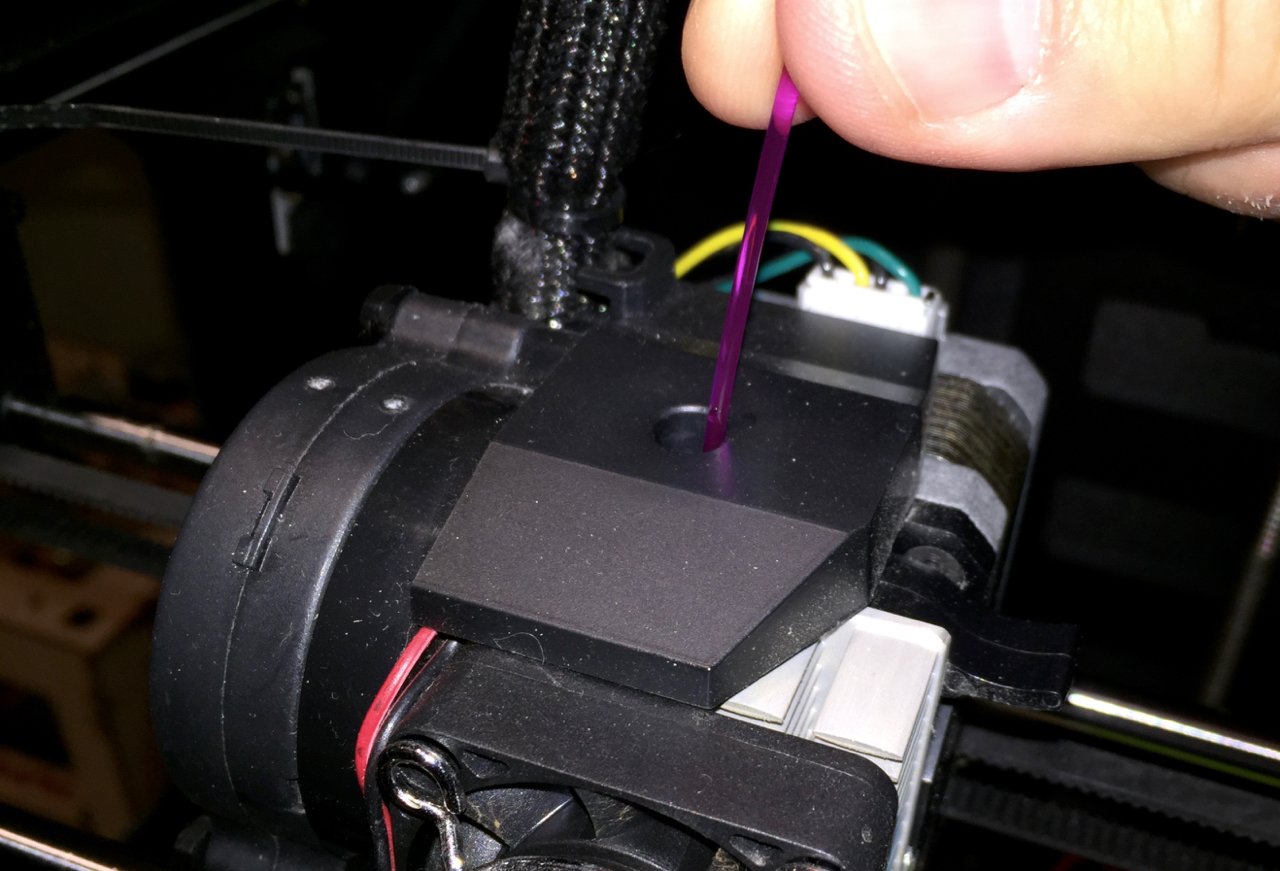

Simply ensure you have a length of filament inserted into the hot end. Cut off the filament as it sticks out of the hot end and keep it about three hand widths long.

Heat the extruder so that you get a drip from the nozzle, or at least hot enough to do so. (It may not if it’s really clogged).

Then turn off the heat and watch it cool down.

Normally when the hot end is at operating temperature you can freely pull the filament out. When it’s cold the plastic is frozen in place and you cannot pull it out.

The trick here is to wait until the temperature is just slightly below freezing level. At that point you can briskly pull the filament out and it should be mostly solid.

And here’s the magic: when it is solidified, it captures random debris that happens to be in the hot end. You pull it out with the filament!

Examine the end you just pulled out and you’ll probably see it polluted with dark stuff, perhaps even some noticeable bits. There will be more inside the solid portion of the filament.

Cut off this polluted end and repeat the procedure. It will take you a some minutes to heat and cool the hot end, but this is far easier than other approaches. Keep repeating as many times as required.

Eventually you’ll get a nice clean “pull”, where the end of the filament is pure. You’re done!

Now, insert the real filament into the extruder, replacing the cleaning segment you’ve been using. Attempt to extrude some plastic using your machine’s control panel and it should work well.

I’ve used this technique many times and it almost always works. In one case it did not; I had been testing a very poorly made wood filament that included actual wood chunks. Needless to say, the nozzle clogged completely within five minutes of use. The cold pull technique did not work and I had to remove the nozzle and burn it out with a blowtorch. More fun than the cold pull technique, but a last resort.