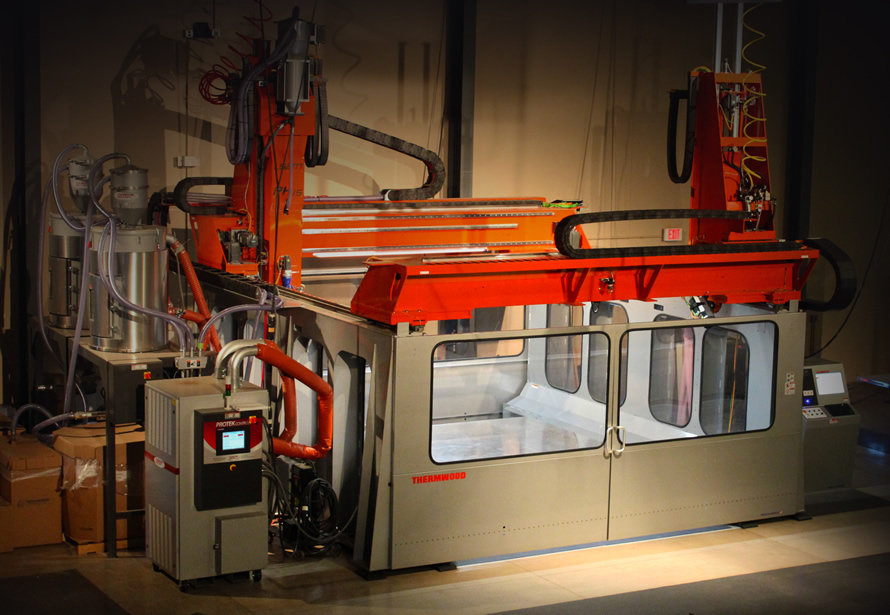

CNC maker Thermwood announced a very unusual device: the LSAM, which combines CNC and 3D printing technologies.

The company has been operating from its Indiana base since 1969, and has primarily been making large industrial CNC machines for the subtractive manufacturing market. Now they have taken a big step into the world of additive manufacturing by announcing the LSAM (“Large Scale Additive Manufacturing”) device.

It’s clearly based on their existing CNC technology, which makes much sense: the mechanical elements have many common requirements. Indeed, some of the CNC equipment made by Thermwood involve far more complex motion control systems, up to five axes of movement.

The LSAM is designed to produce large-format parts, jigs, fixtures and molds for industrial purposes. When I say large, I mean it. Thermwood explains the build volume:

LSAM machines feature a ten foot wide, five foot high work envelope. Length of the work envelope can be as short as ten foot but as long as 100 foot or more.

While the large size is interesting, the real magic feature is the second stage of this machine: it includes a five axis CNC machine.

What’s that for? The idea is to finish the print by milling the surface to the desired degree of smoothness. It’s the best of both additive and subtractive processes.

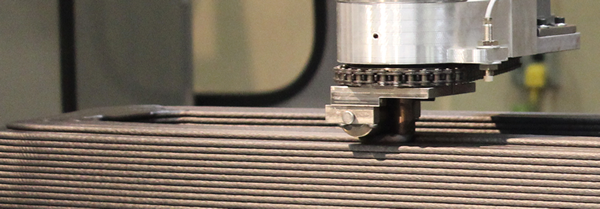

But I suspect the true reason for the CNC stage is that the print is quite coarse, as seen in this extrusion image.

The prints would be completed quickly with that layer height, and that would be highly desirable for the size of these prints.

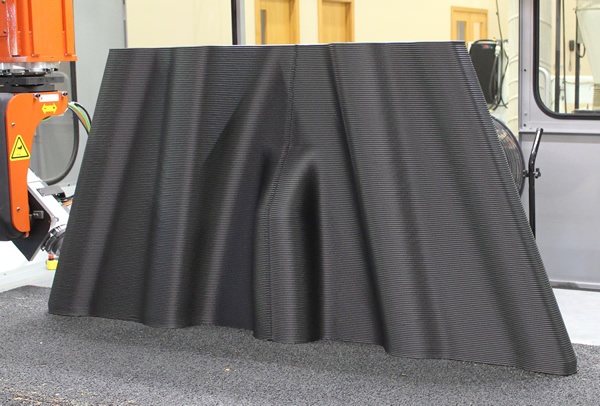

There is a major constraint, however. The primary advantage of 3D printing technology is the ability to produce objects with “impossible” geometries. And that’s “impossible” by the standards of CNC machines.

Thus the LSAM, if using the second CNC stage to finish the entire surface, would be constrained to produce only objects that can be made by CNCs.

It’s likely there are still many useful objects that can be produced by this combination of tooling, making the LSAM productive for industry.

I also have questions about the plastics used by this very large machine. While the company explains that materials up to 650F (343C) can be used, it’s not clear how they avoid warping, distortion and ensure accurate dimensionality. Some machines do so by thermally controlling the build volume, but the LSAM appears to have a completely open top, allowing heat to escape.

It should be interesting to see what uses the LSAM can perform.

Via Thermwood