3D metal printer manufacturer Höganäs delivered a new machine to a client this week, but it’s not a typical client.

Readers may recall my enthusiasm upon discovering Höganäs last year. The Swedish company produces metal powders for additive manufacturing, but also develops and markets their own 3D metal printing equipment.

The 3D metal printer, shown here, is one of their models. But it’s not the appearance of their equipment that is of interest. No, it’s the print quality.

Here we see a ridiculously small chess piece, 3D printed in very fine detail – and it’s solid metal. Their Digital Metal process is able to produce these parts using a cold process for “green” parts, which are then fired in a hot furnace to complete their production.

The resulting parts can have 97% density and up to 0.035mm resolution.

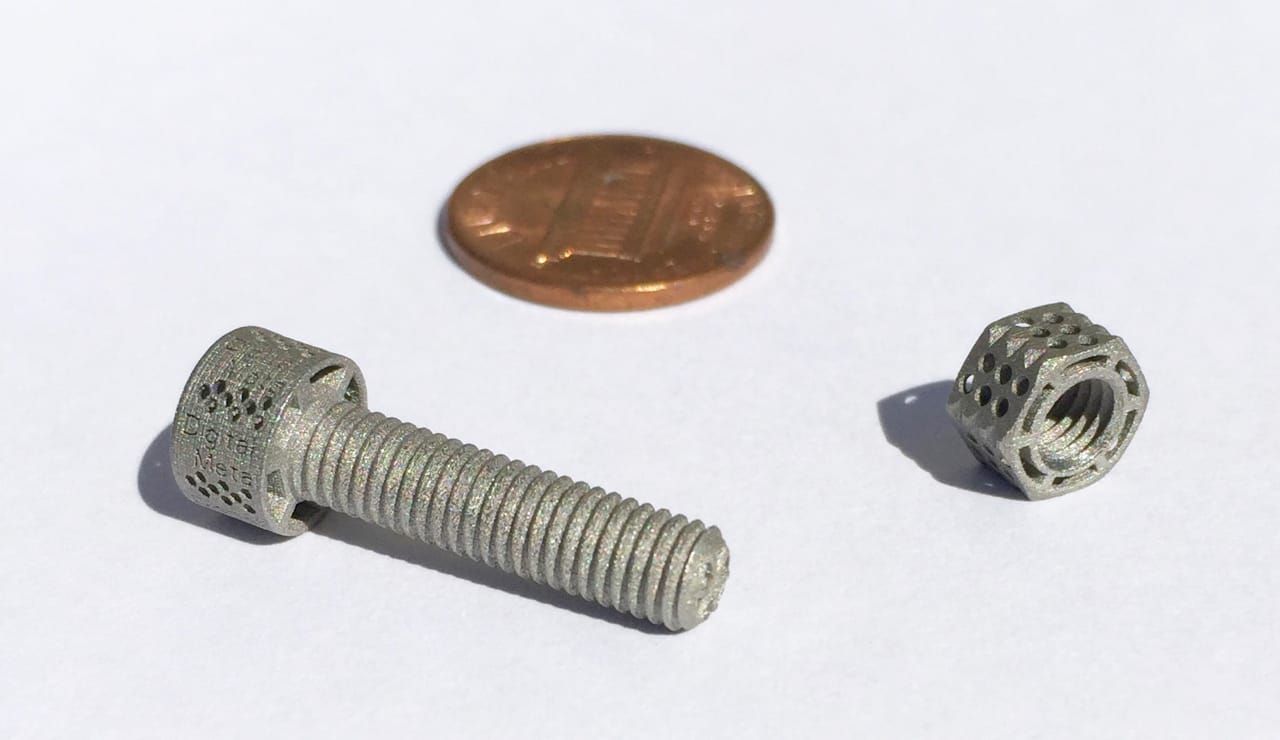

Why is this so important? Because you can make stuff like this:

These are lightweight, but still sufficiently strong, bolts. They can only be made by super-high resolution 3D metal printing processes and suggest new ways of reducing weight and material use by manufacturers.

Imagine how much weight an aircraft could lose if all of its bolts were made in this way? That could be significant.

But so far, I don’t believe this approach is catching on due to the relatively poor resolution of many 3D metal printers. With the Digital Metal process, you can produce extremely fine details enabling this approach.

This past week Höganäs delivered one of their systems to a client, which normally isn’t news on this publication, but I noticed that the client was CETIM of St Etienne, France.

What is this CETIM centre in St. Etienne? They explain (translated from French):

The Technical Center for the Mechanical Industries was created in 1965, at the request of the mechanical industry, in order to give companies the means and skills to increase their competitiveness, participate in standardization, link scientific research and Industry, promote the advancement of technology, help improve performance and guarantee quality.

Today, these objectives are translated into different missions of anticipation, innovation, diffusion and services.

and

This site is located in the first region of mechanics of France and in the heart of a basin rich in mechanical companies. Like the other two Cetim sites, it meets industrial needs in each of its areas of specialization at the national level and offers proximity services adapted to the needs of companies in the mechanical sector.

It actively participates in the actions of the Rhone-Alpine devices and the Loire department dedicated to the development of the mechanical industry. It is home to one of the five regional technological platforms oriented mechanically.

In other words, it is a service for industry in France to assist in innovation and entrepreneurship in mechanical industries.

It’s a place where new approaches can be shown directly to industry.

It’s now a place where this high resolution 3D metal printing can be demonstrated.

It’s a place where the lightweight, small parts design approach could launch.

That’s why I feel this particular delivery is important.

Via Höganäs