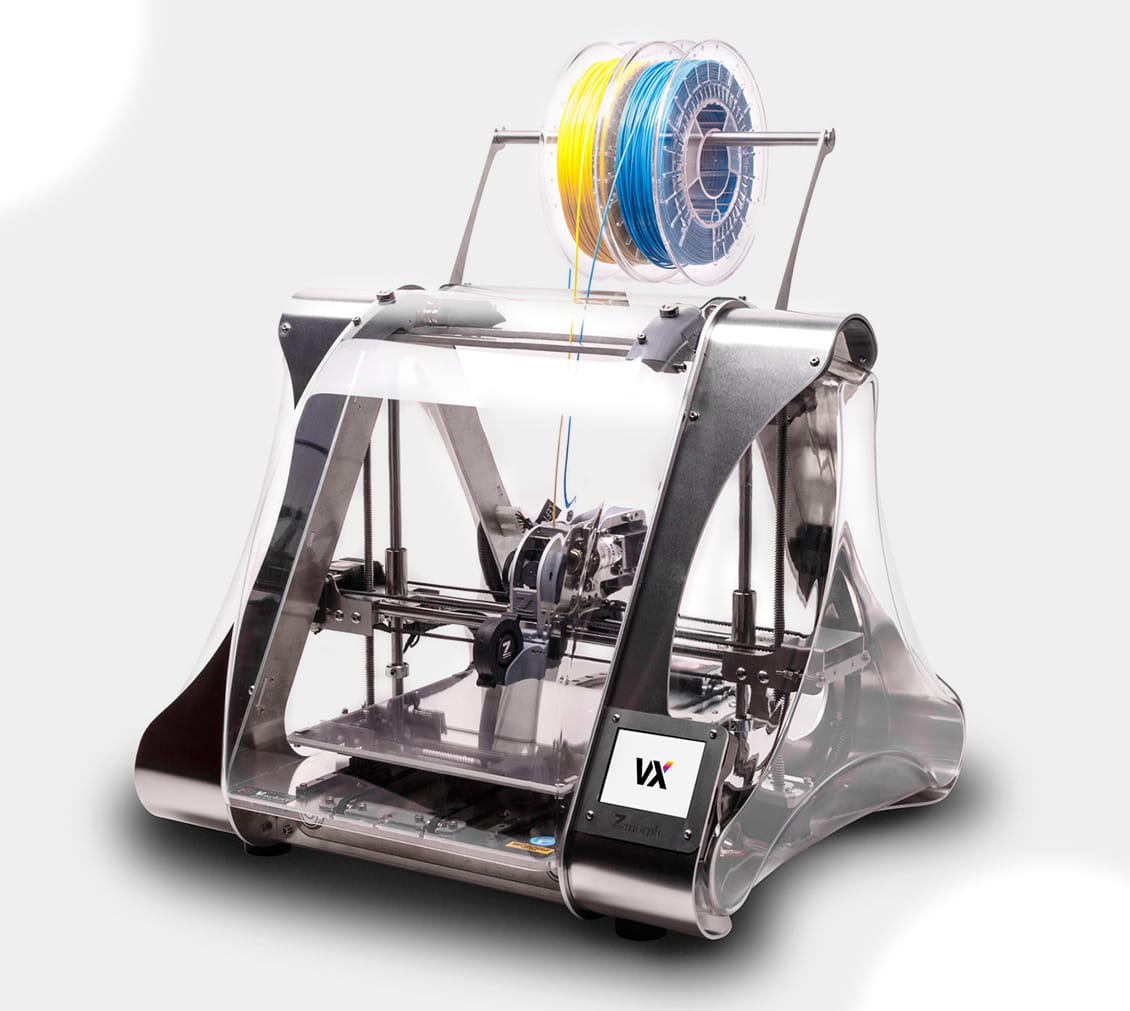

Poland=based Zmorph announced a new version of their increasingly powerful multitool desktop 3D making device.

The Zmorph VX is the new unit, and appears to be a much improved version of their previous Zmorph 2.0 SX, and most definitely inherits the multitool features that made the SX a unique machine.

In addition to hardware changes, Zmorph has also introduced significant software and pricing changes.

But back to the hardware. A fully-equipped VX will not only 3D print capability, but also CNC milling, paste extrusion and laser etching, as did the SX. Note that with the milling feature you will be able to make custom PCBs, as well. But although the functions are the same, the hardware has improved to make the system more reliable and more accurate.

Several specific changes make this happen. The motion system and frames has been upgraded, with the introduction of linear guides and a reinforced X-axis, as well as a stiffer X-Y axis.

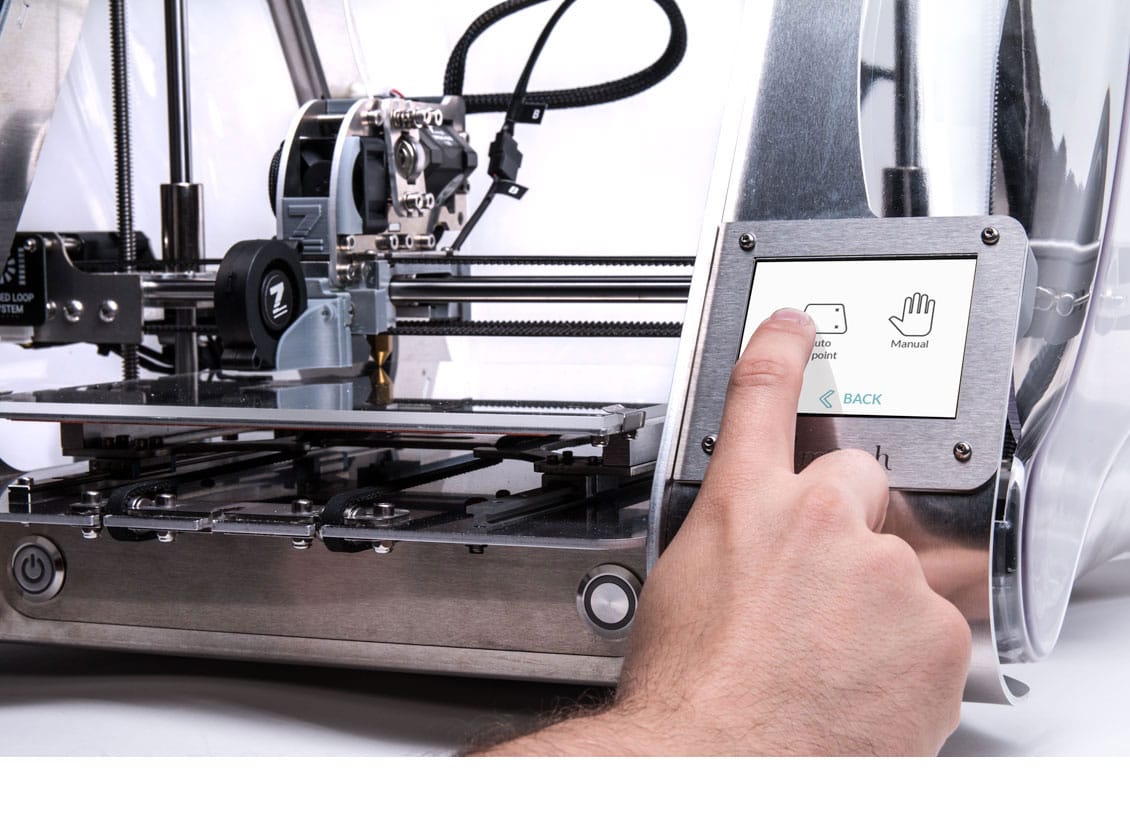

Perhaps most importantly, the VX now includes a fully automatic calibration system. The previous system utilized an assisted system that required the operator to perform tasks, making usage a bit slower.

These changes will improve all tools’ results.

For the 3D printing tool, there have been additional improvements. First, the print surface has been replaced with a borosilicate glass plate, still heated, which should provide even heat across the surface. The extruder has been completely redesigned and now includes injection molded parts that should be stronger. The hot end now includes a way to quick swap nozzles for adjustment of resolution, be it coarse or fine. There’s also an improved cooling system that should freeze freshly extruded material faster, which will increase part quality.

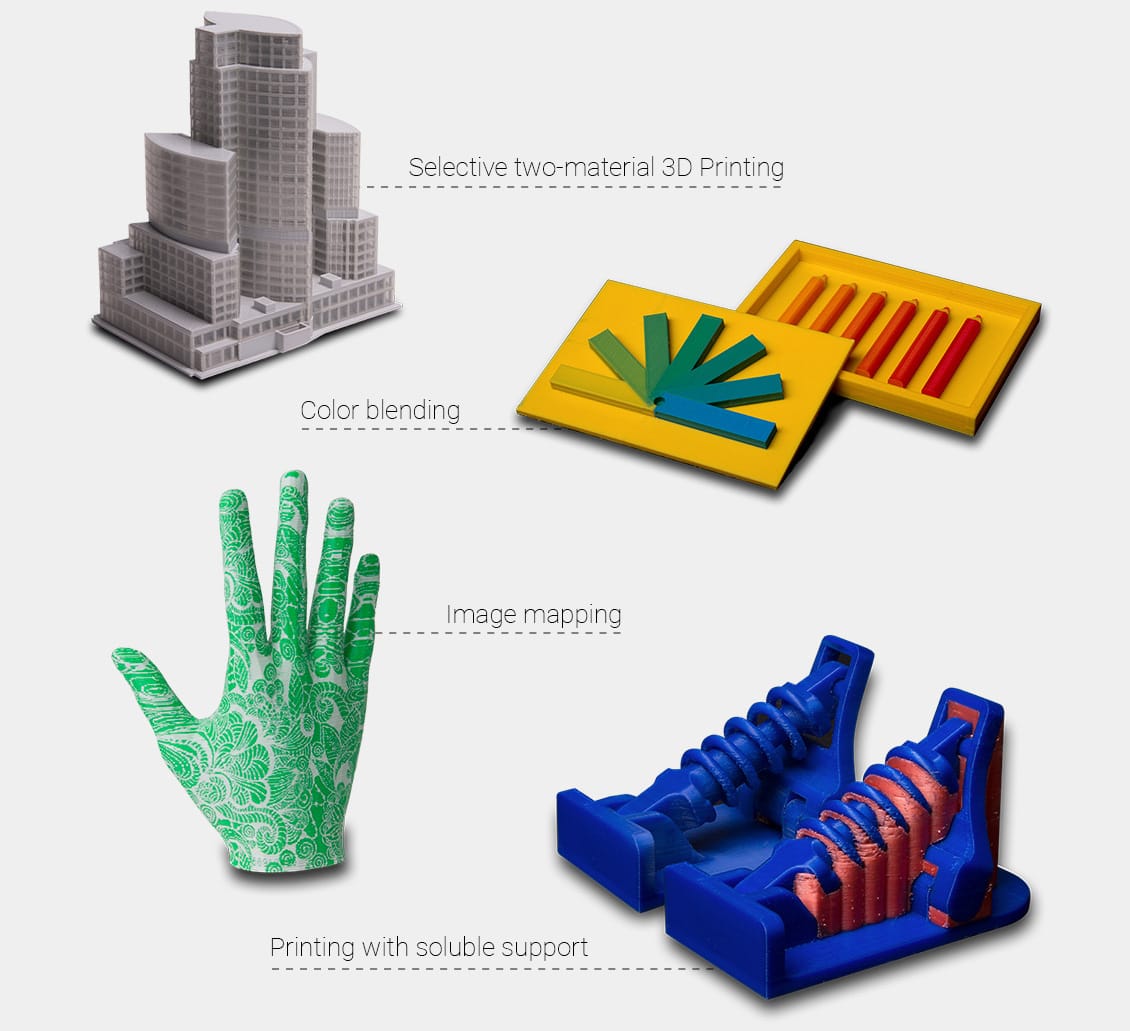

Oh yes, there is one more extruder improvement I should mention: they have a blending system! This is a configuration where two different filaments (perhaps two colors, or one support & one model material) are selectively extruded through a single nozzle, eliminating the complexity of typical dual extrusion systems.

The ability to 3D print soluble support implies this 3D printer should be able to produce very complex parts, making this machine suitable for professionals.

For the CNC and laser tools, the VX has a new detachable worktable that includes pre-measured holes for more easily strapping down milling or etching material.

The VX is now set up to enable a complete tool swap in less than a minute, which is great news.

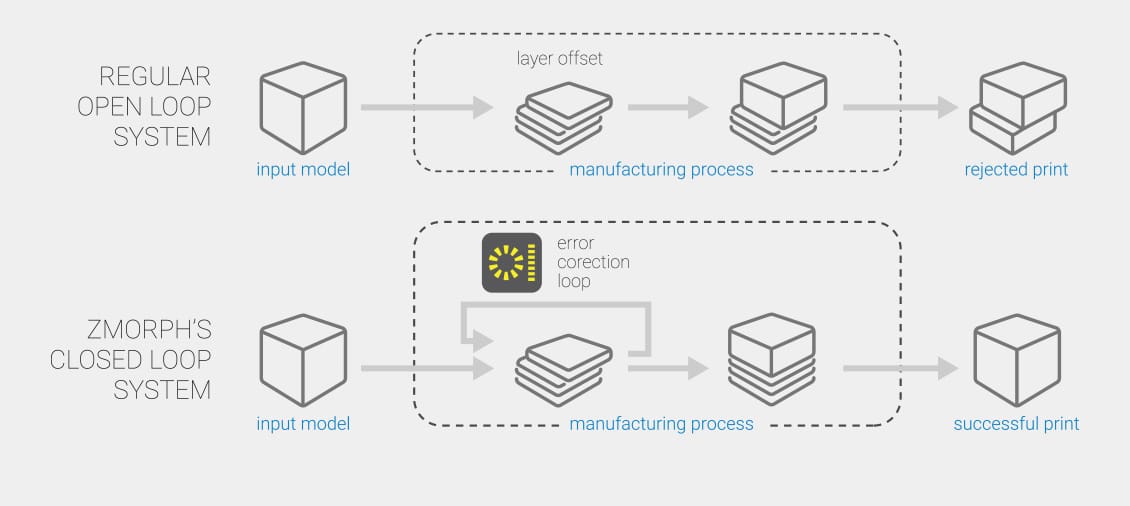

The VX includes a “closed loop” system that monitors for errors and adjusts on the fly, making the probability of success much greater.

I suspect the biggest change is in the software that drives the VX: Zmorph’s Voxelizer software is used to load digital models and prepare them for 3D printing, milling or laser etching. As you might imagine, bundling all these functions together is quite a challenge, because each of the tools involves different twists on making that must be accounted for. The previous version was a bit complex to use, particularly for beginners. Now that’s changed. Zmorph explains:

From the software side, there’s the completely revamped Voxelizer softwar, with clearer, beautifully designed interface, prepared both for inexperienced beginners and pros wanting to grasp full control of the printing process. What’s more, the software has been updated with faster and smarter algorithms such as 3d filters, with the goal to help users make

unprintable models printable.

This is great news, as the software is the interface through which the entire system will be viewed by the operator. If it works well, then good making results will happen.

That’s not all. The company has developed a different approach to pricing the system that’s a lot more flexible. It seems that everyone might not want particular combinations of tools, so Zmorph now offers, among several fixed prices, the ability to “custom quote” for a specific combination of tools. For example, you might choose the 3D printer and paste extruder tools. Or perhaps you might want a different configuration. If so, they’ll price it out for you.

Pricing starts at USD$2,799 and ranges all the way up to USD$4,399 for the “ZMorph VX Full Set”, which includes all tools: Single Plastic Extruder, Dual Extruder with Mixer Hotend, CNC, PRO, Laser PRO, Thick Paste Extruder. There should be something for everyone here.

However, the VX is not a machine for everyone, because you might be interested only in one or two of the functions. Zmorph aays the machine is targeted at two groups: professionals and educators.

This makes sense because educators typically work in classrooms without a lot of space for equipment. The VX essentially places a number of different making tools on a single footprint.

Similarly, a professional office, perhaps an architecture or design firm, often does not operate their own equipment and outsources work. The Zmorph VX would enable such offices to do at least some of the work in-house, perhaps saving on outsourcing costs and actually paying off the Zmorph VX purchase.

Finally, I’d add that the ZMorph VX may also be suitable for advanced DIY hobbyists who have limited workspace – and budget. After considering the cost of separate machines for all these tools, it would most likely be less expensive to pick up a VX.

Via Zmorph