I sat down with HP’s new Global Head of 3D Metals, Dr. Tim Weber, to discuss Metal Jet 3D printing.

It’s been a long ride with HP Inc. as the global printing giant has entered with aplomb into the 3D printing industry. Building upon decades of expertise in inkjet technologies, launching Multi Jet Fusion and now Metal Jet 3D printing technologies has been a major move for a major company. I’ve had the pleasure of following the story from the ground, on-site at HP’s Barcelona facility in my previous position for the pre-RAPID unveiling of MJF and last week for Fabbaloo as a hosted guest of HP Inc. as Metal Jet had its first public showing at IMTS.

Between the many presentations and festivities surrounding the launch, I appreciated a quiet sitdown with Weber to discuss the new technology.

“Our Corvallis lab investigations have included metal; we identified binder jet technology as an interest and really got going about a year ago… Metal Jet is a new technology, one we believe is disruptive,” Weber began.

In Corvallis, Oregon, HP’s Open Materials Innovation Lab houses significant resources; it was there that, in my previous position, I had first met Weber to learn more about HP’s approach to materials in its 3D printing operations. Now that these materials explorations have expanded to encompass metals, the team at Corvallis, as well as the partner companies HP is working with, are keeping busy indeed.

“During our presentation last week” — the Virtual Press Briefing, where we first learned the details of Metal Jet from Weber — “I said that HP is the best printer producer out there. But we’re not best in materials, or in other areas; so let’s partner. We’re doing here what we did with plastics.”

Partnerships have been integral to HP’s approach to and success in the 3D printing market. Leveraging internal expertise in printing to develop its technologies, the company has seen the benefit of working with standout leaders in materials, software, and areas of application to create a more successful ecosystem as a viable solution in additive manufacturing.

Looking to strategies in the rollout of Metal Jet, Weber noted that the timing is important as the graduated market introduction allows the company to maximize feedback.

“With the metal production service, it’s better to get customer input earlier, rather than introduce it and then hear, ‘This isn’t what I needed.’ We’re leveraging what we’ve learned with plastics. We want to get this out sooner, get it on the ground,” Weber explained.

“I’m a mechanical engineer; I’ve been doing this a long time. It can take years. We wanted to prime that pump. This isn’t to do one part, but to see if it makes sense for production, to get feedback. I think that’s what startups should do.”

A well-planned market strategy to position a new technology offering is critical to early success. The choice to begin with production service with partners, rather than immediate machine sales, allows for an enhanced feedback process to gain user insight into what works, what needs attention, and what the next steps can be for a smooth rollout.

It was interesting, as well, that the introduction was slated for IMTS; MJF came onto the scene with a major launch event at 3D printing-focused RAPID 2016, while in 2016 additive manufacturing occupied a small fraction of floorspace at the manufacturing-focused IMTS. Why debut at this event, rather than wait for the fast-approaching formnext, which will bring 3D printing together at this industry’s largest show?

“The decision for the IMTS launch was made earlier this summer,” Weber told me. “We’re doing mass production; where would a tooling company do it? IMTS was the best place to announce.”

Displaying in the Additive Manufacturing Pavilion at a major event surrounded by traditional manufacturing technologies, Metal Jet presented a clear message of its manufacturing orientation.

Of course, it wasn’t alone in that; as additive manufacturing continues to move toward manufacturing and more companies join the quest toward mainstreaming AM in production, IMTS saw a fair amount of new 3D printing systems, particularly metal-based. Competition is picking up.

“I’ve seen a lot of lasers, a lot of automation,” Weber said when I asked about other IMTS launches. “I’ve been so focused on [the HP Metal Jet launch], but what I’ve picked up from walking through the show: everyone is focused on production. We’re observing a shift in our industry. At the end of the day, manufacturing is driven by economics.”

That last point hammers in the reality of what’s necessary for true manufacturing viability: competing, not with other additive introductions, but with traditional offerings.

“You must have an equivalent or lower price. The focus is on enabling manufacturers to do things cheaper. We’re looking at 50,000 parts, which is lower-volume production, but as we’ve seen with Moore’s Law, this is a good starter point,” Weber told me, emphasizing a slide shown in the VPB and in HP 3D Printing President Stephen Nigro’s keynote that details the doubling of inkjet performance — Moore’s Law — every 18 months. “What we’ve seen in plastics, expect that in metal.”

HP’s plastic work with MJF has undeniably been making waves in both prototyping and production. The ambition to continue that trajectory, with a focus on the production side, with metals is well in line with the company’s consistent messaging in seeking leadership in the 3D space.

One of the lessons HP will be transitioning into its work with metal, Weber noted, is its approach to materials: start with one. While MJF has built a strong foundation in nylon, expanding that portfolio, Metal Jet is starting with stainless steel.

“We’re going to start with one material and really nail that, end to end. Develop all the process controls there. Then we will systematically expand into other steels. The approach is market-driven,” he said.

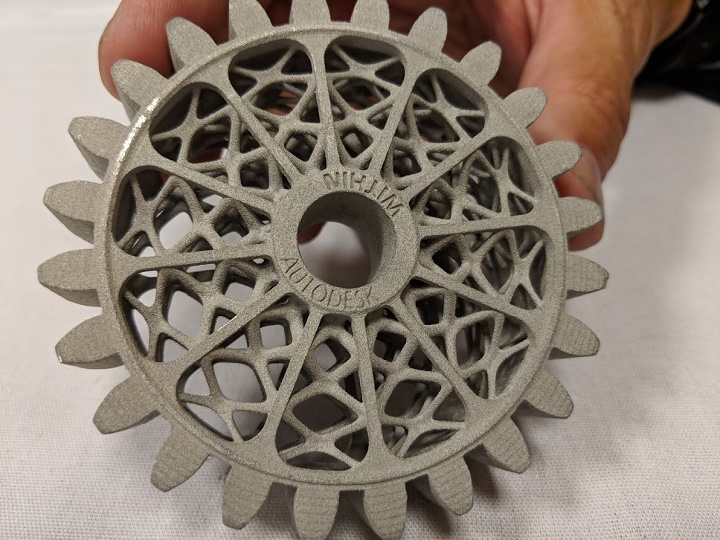

Ultimately, Weber emphasized, everything HP is driving forward with its 3D printing activity is “all about the applications.” Mass customization for fluid dynamics and other applications that can leverage the unique benefits of additive manufacturing will enable additional capabilities for HP’s partners and customers as the technology continues toward the mainstream.

[All photos: Fabbaloo]

Elizabeth C. Engele (Lizzy) is a designer for social good, and a founder of MakerGirl.