![Matt Denton, his nephew Ruben, and their giant 3D printed LEGO tractor [Image: Matt Denton via Thingiverse]](https://fabbaloo.com/wp-content/uploads/2020/05/giantlegofinished_img_5eb09f480a5d1.jpg)

LEGOs have inspired generations of makers, and that hasn’t changed with exposure to 3D printers.

Matt Denton is the mastermind maker behind such impressive achievements as BB8, the droid in the most recent Star Wars movies; a T-rex for Jurassic World; and a massive rideable robot spider. So, you know. A very normal resume. Robots, electronics, and building — and it all started with a childhood interest in building with LEGO blocks.

Now he shares that enthusiasm with his nephew, Ruben, who helps him put together LEGO kits. Really big LEGO kits.

Denton 3D prints massive LEGO blocks and puts them together according to kit instructions from real LEGO projects. A go-kart, a forklift, a bulldozer, and now a tractor showcase his scaled-up 3D printed LEGO blocks. The tractor is his newest, released around Christmas to highlight the festivity of the season. (Is a tractor festive? Well, it’s red, so according to Denton and Ruben, yes, yes it is very festive.)

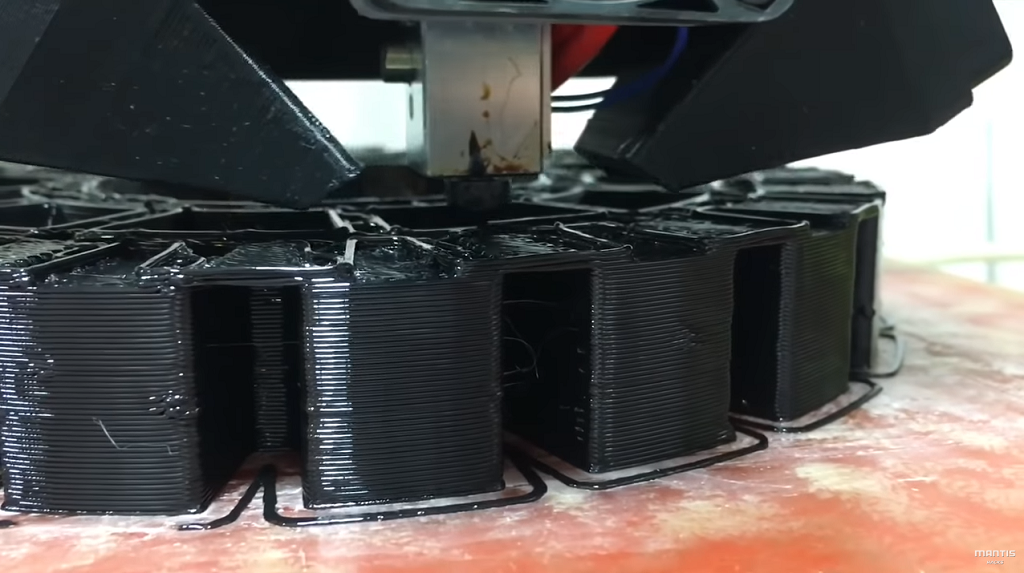

For the LEGO tractor — built from a 1977 kit (851, or in the US, Expert Builder kit 952) — Denton put his collection of LulzBot TAZ 6, TAZ 5, and Mini 3D printers to use in more than 400 hours of 3D printing to create more than 250 parts.

![Child’s head for scale [Image via YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/giantlegowheel_img_5eb09f4880275.png)

Big parts mean big printing, and the MOARstruder, introduced two years ago, helped Denton create large-scale pieces faster. Five times larger than the original LEGO set, the wheels on the giant tractor are “bigger than my head,” by Ruben’s reckoning — the boy could easily put the tire over his head. Denton printed the tires in four parts, with each quarter needing 13 hours of print time using the 1.2mm MOARstruder with PolyFlex material. Afterward, they were assembled with keyways and glue.

Denton also used the 0.5mm LulzBot Flexystruder, and other materials included Polylite PLA in red, grey, and black.

One of the most charming things about Denton’s builds, aside from the obvious cool factor of giant LEGO stuff, is his partnership with his nephew. Play is an important way of building interest, and that spirit of playful exploration remains critical as we get older — and indeed continues to inspire the next innovations in 3D printing. Many engineers and designers started with youthful interest in building sets, and that interest can continue to build (pun intended) with 3D printing.

![Assembling the 3D printed tractor - and learning about universal joints [Image via YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/giantlegoassembly_img_5eb09f4a72f95.png)

Exposure to new technologies is picking up in schools, with students as young as kindergarten increasingly being introduced to 3D printers in the classroom. Hands-on experience with 3D printing can help foster creativity and understanding. Some great moments in this particular build video show Denton explaining the workings of various joints and design elements as Ruben learns about not only building mechanics, but the actual functions of tractors.

Check out the full build below:

Like all his large-scale LEGO-inspired builds, Denton has made the files available on Thingiverse.

Via YouTube

‘Tis the season to celebrate the best of 3D printing.