![3D printer components are a big part of a machine’s longevity [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/3d-printer-components-1_img_5eb095ad0be79.jpg)

I’ve been thinking about machine longevity, and you should too.

Longevity is, of course, the expected duration of a 3D printer lifetime. This factor is extremely important for several reasons.

First it affects the financial analysis of the machine and its original purchase. If an investment is to be made to acquire a 3D printer for, say, five years of use, then the purchase and setup cost can be spread out over that same time period.

If the expected lifetime of another machine option were to be a lot less, say only two years, then the effective per-month cost of using that device would be quite a bit more, even though the sticker-price purchase cost of the machine might be the same as the five year option. Let’s do some math:

-

A US$5,000 machine being used for five years costs around US$83 per month

-

A US$5,000 machine being used for two years costs around US$208 per month, more than twice as much.

This is why you should consider the longevity of a device when you purchase it. Because if you choose poorly and have to re-buy the machine or equivalent frequently, you are actually spending more money than you need to.

But what makes a machine last longer? One critical factor is the amount of use it’s going to undergo during its operational lifetime. Some 3D printers are running more or less 24×7, particularly those very expensive industrial devices; the idea is to use them as much as possible to pay off the huge purchase cost.

But other machines, particularly hobbyist or professional machines, are used on a less predictable basis. Sometimes machines actually sit idle most of the time, making it pretty easy to stretch its “lifetime”. But there are an increasing number of professional 3D printers that are being used for low-volume production.

This is due to the extreme cost of tooling up for mass production. Traditional manufacturing is costly unless you intend on making a very large number of parts. But in today’s world there are an increasing number of scenarios where smaller numbers of parts are required, and 3D printing is ideal to do so, as there is no need for tooling. Just print.

It’s the 3D printers being used for this purpose that must keep a close eye on machine longevity. Machines selected should include many features that ensure longevity, but what are they? Here are some ideas:

Robust Basic Components

This one is obvious, but using the cheapest fans, chips or belts is really not the best plan for ensuring the machine is going to last a long time. The vendors that do use premium parts will say so; the others often stay silent on such matters. Best to ask or otherwise investigate the quality of the components used.

Thermal Separation

Many recently released machines attempt to increase print quality and reliability by enclosing the build volume and capturing heat within it. This is great for the materials and printing, but definitely not the best idea for electronics and plastic belts, which will wear out far more rapidly if exposed to heat. Some more advanced designs actually separate these two functions into a hot and cold zone. One example of this is FELIXprinters, whose machines all include this feature. On examining a 3D printer, try to see what is in the hot zone and what is not.

Consumable Hardware

Some machines sport components that are actually designed to wear out and be replaced. MakerBot’s Smart Extruders, for example, are considered a consumable and must be periodically replaced. While this certainly adds costs, it does help extend the lifetime of the machine. Imagine if this component were not replaceable? How many other machines have non-replaceable extrusion systems? What other components could wear out and not be replaced? The print surface? The nozzle?

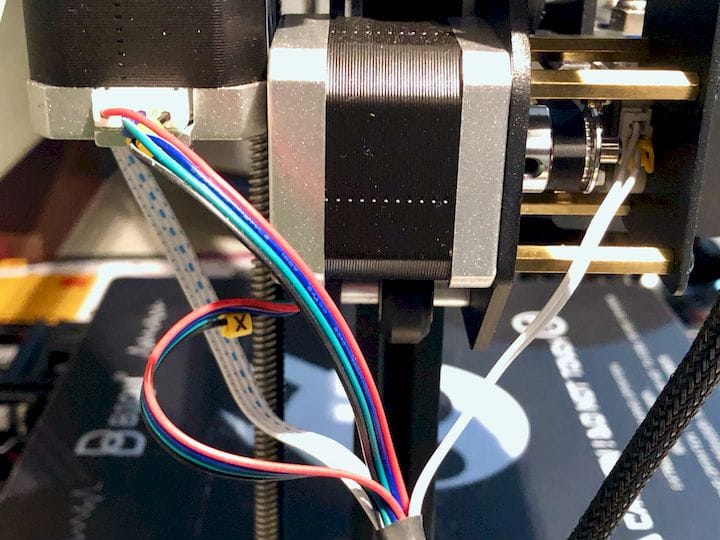

Cable Stress

Of the few printers I’ve used that have actually worn out, the reason is often because a cable has flexed too much and broken connections. One feature I always look for in a 3D printer is how the cabling acts with the motion system. Does it bend the cabling a lot? Is the cable twisted and pulled? While some wiring is well designed, others seem destined for early failure.

Those are a few things I always think about when examining a machine option and considering how long it might be able to run.

No one seems to offer collaborative 3D printing modes on dual extrusion devices. We explain why this is the case.