There could be some profound implications coming for additive manufacturing, after a review of the newly announced HP Universal Build Manager, which is powered by Dyndrite.

Where do I start? There are so many pieces in play here. Well, perhaps let’s look at the players involved first.

HP and Dyndrite

HP has been gradually building a first-class additive manufacturing business, starting over ten years ago with some reselling experiments, then leading up to the announcement of their own equipment only a few years ago. Since then they’ve increased the capabilities of their equipment, all the while focusing on the idea of additive manufacturing for production.

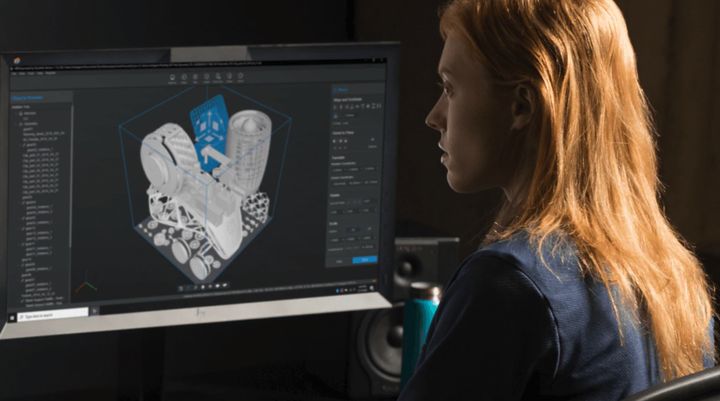

Dyndrite is a startup company that has developed something very unusual: a 3D software engine that can process massive 3D models at lightning speed.

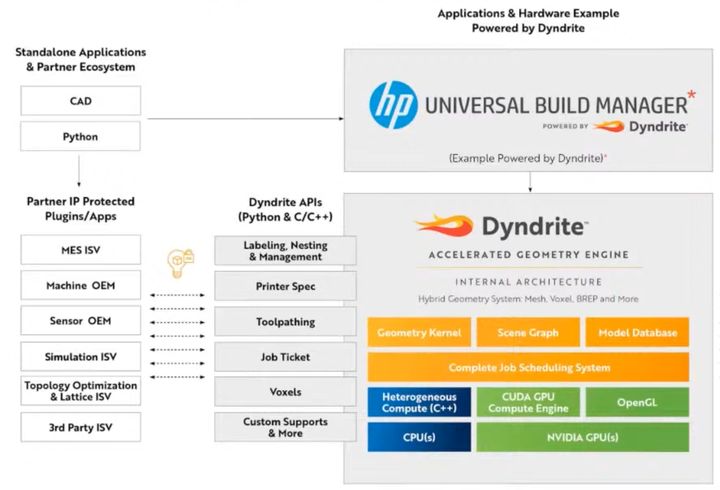

The big announcement last week dealt with HP’s new “Universal Build Manager”, a software system for preparing jobs for 3D printing, but one specifically designed for production. As a relative newcomer to the space, HP wisely chose a partner to help them power this software, Dyndrite. Thus the HP UBM will be able to take full advantage of Dyndrite’s speed and other capabilities.

HP UBM Production

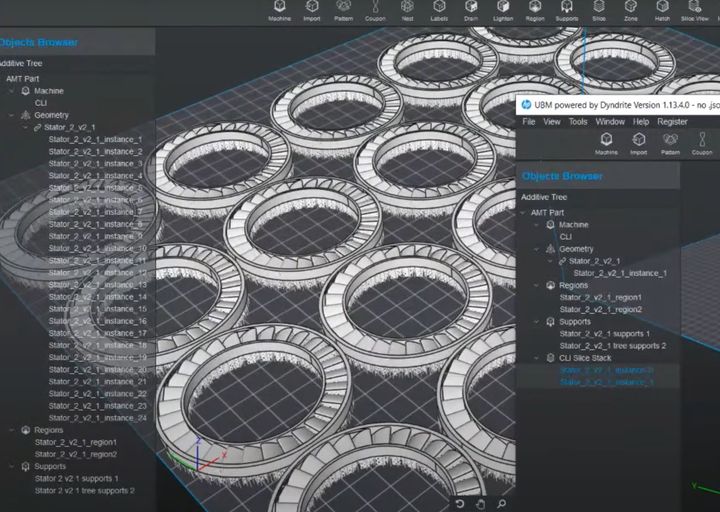

When I say UBM is designed for production, it might not be clear what that means. After watching some demos it seems that this means focusing around the build layout. “Layout” is a concept well-understood in 3D printing and refers to the act of arranging objects on a build plate for printing, and specifying the print parameters. Most 3D print slicing systems allow you to save this “job” configuration in case you want to use it again.

That can be done in UBM, of course, but they take this step a lot farther. Way, way, farther.

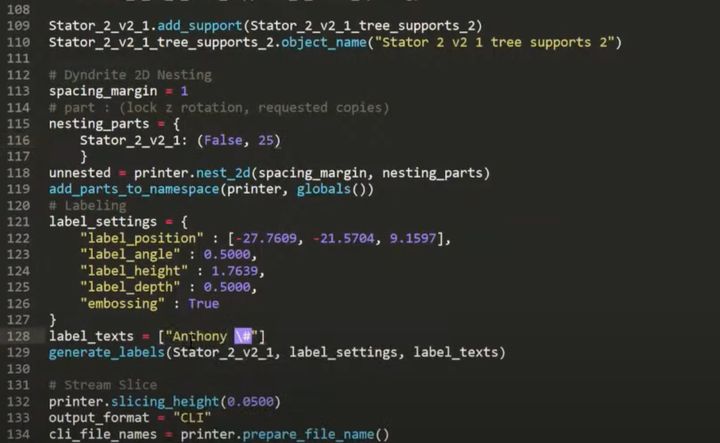

Instead of the “job” being a static item, it becomes dynamic in UBM. You can very easily change parameters, shift around objects and more. One feature that’s interesting is the ability to create a “label” on an object, and when processed the label is transformed into serial numbers applied to each object instance.

But the most surprising thing is that the print job is stored in a control file that’s composed of Python statements. Python is a very popular, perhaps the most popular, scripting language used by programmers today.

By putting the job into a Python file it can then be edited by a programmer. Want more of those objects? Just change the number. Want to rotate the objects five degrees? Just change the rotation angle in the file.

But wait — that’s not the most important feature. For me, it is that this file can be changed by other scripts! You could, for example, create a script to modify the print job by accepting some input parameters and making changes in the Python file.

The implications for this are huge, as this means a production operation could directly integrate the creation of print jobs to a manufacturing system. Ultimately, this could result in someone selecting a part from a catalog, selecting some personalization or providing measurements, and having the entire production process automated from that point, slicing included.

I could go on about that for a while, but there’s even more to consider with UBM.

UBM For Non-HP Equipment

HP has made the decision to NOT keep it exclusively for HP equipment. They have designed the software in conjunction with Dyndrite to segregate components in such a way that another vendor could make use UBM without having to expose any of their intellectual property. This makes sense, as there is core functionality and then there are the peculiarities of each device that are simply added on.

HP has designed UBM to handle these 3D printing processes:

- HP Multi Jet Fusion (Polymers)

- Binder Jetting (Polymers, Metals, Ceramics)

- Powder Bed Fusion DMLS/SLS/SHS (Metals)

- EMB (Metals)

- SLS (Polymers)

- FDM (Polymers)

- SLA/DLP (Polymers)

- LOM (Composites, Ceramics, Glass)

- CBAM (Composites, Glass, Ceramics)

That list pretty much comprises ALL major 3D printing processes, meaning UBM could theoretically be used with virtually any currently offered 3D printer. Note specifically that it includes processes NOT OFFERED by HP.

Dyndrite Engine

And those who do would gain access to the ridiculously powerful Dyndrite engine.

During the demonstrations I watched, it was astonishing how fast the system was able to process complex models. The system was processing them faster than the operator could react, essentially instantly. This is of critical importance because as we move forward equipment will increasingly gain resolution and 3D models will gain complexity. These factors will make it increasingly difficult to process models for manufacturing with existing software solutions.

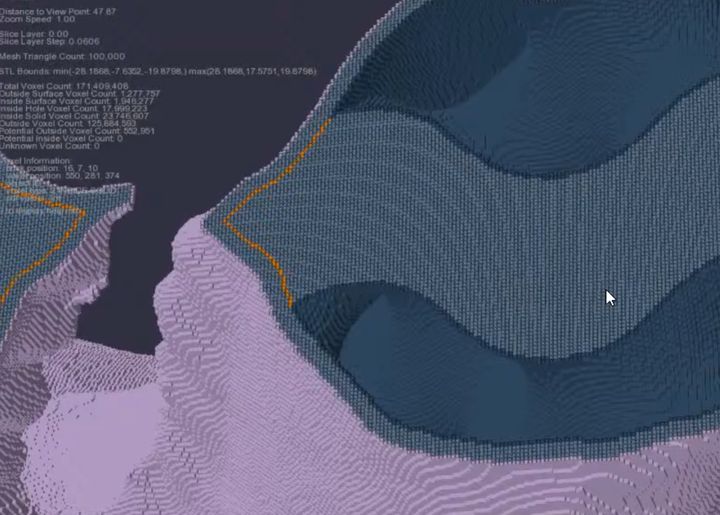

Dyndrite includes a system they call the “Voxelator”, which is a way to reduce a 3D model to voxels, or building blocks, like one would seen in Minecraft. However, in this system these voxels can take on many different properties.

Combine this with the ability to directly import CAD files (rather than meshes like .STL or .OBJ), the system then has access to more information about the intention of each structure and can thus take action.

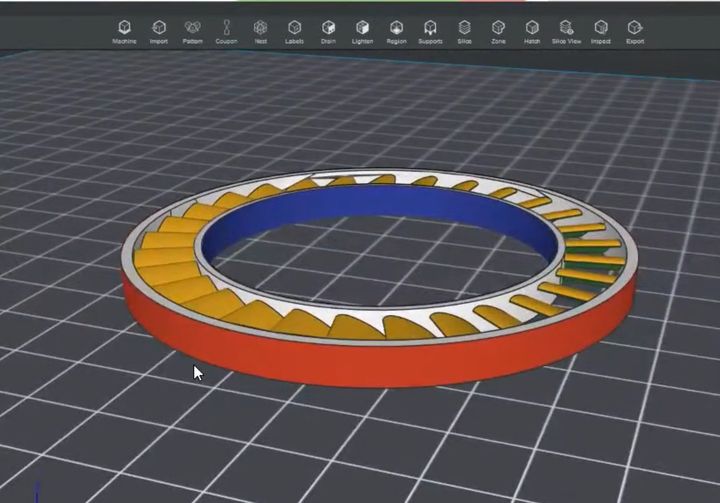

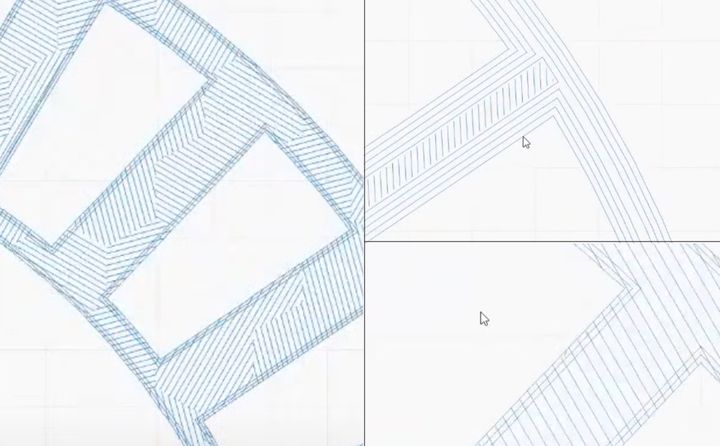

This allows the Dyndrite engine to perform incredible feats of slicing that I have never seen before. For example, one could adjust the inner orientation of extrusions in this example:

Factors such as color, temperature, and others can now be manipulated on a voxel level to achieve 3D print functionality not previously imagined. We are all going to have to think about this for a while.

Using HP UBM

HP announced partnerships with a number of other parties in the space, who presumably will at some point be offering UBM optimized for their equipment. The list includes:

- Aconity3D

- Aon3D

- Aurora Labs

- EOS

- Essentium

- ExOne

- Open Additive

- Photocentric

- Plural AM

- Renishaw

- SLM Solutions

Note that the list does not include several notable players, including 3D Systems, Stratasys, Formlabs or others. However, there are some companies that are part of the Dyndrite Developer Council but for some reason not part of the HP UBM system. Perhaps they will develop their own equivalent of UBM? They include:

- 3D Systems

- Altair

- Desktop Metal

- Impossible Objects

- Additive Industries

- TRUMPF

- AddUp

- EnvisionTEC

It may be that these companies will eventually join this consortium, as it appears the UBM functionality is quite compelling, particularly for those intending on using additive manufacturing for production. Either that or they will have to compete against the Dyndrite engine on their own, and I am not aware that anyone else is developing an alternative.

By the way, it’s now possible to sign up for the HP UBM Beta program at their site. I suspect a great many people will do so.

Via Global Newswire, HP and Dyndrite