![Results of Xometry’s interesting vibratory test [Source: Xometry]](https://fabbaloo.com/wp-content/uploads/2020/05/xometry-testing_img_5eb050935e868.jpg)

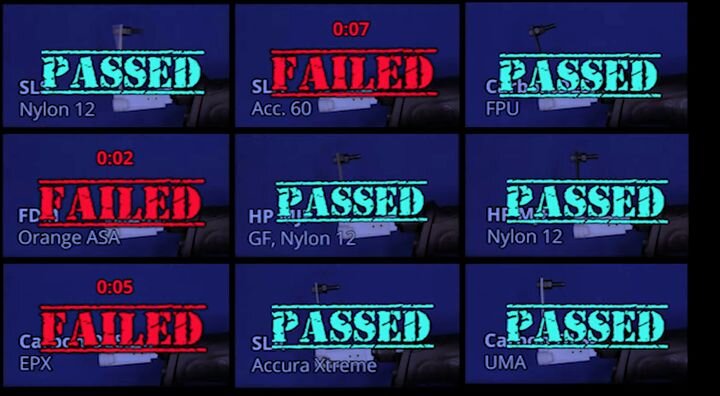

Xometry published an interesting video with an unusual test of 3D prints.

The Maryland-based company operates a now-massive manufacturing network with over 3,000 participating suppliers. They provide making services in injection molding, casting, sheet metal fabrication, CNC and, of course, 3D printing. Apparently they’ve provided over 1M quotes to requestors.

Recently they published a fascinating video showing tests of a number of different materials and 3D printing processes. I’ve seen many tests of 3D prints previously, most notably on Stefan Hermann’s CNC Kitchen channel, where the engineer has devised his own testing equipment.

However, Xometry’s test is quite different: they are testing vibratory capabilities.

Xometry Materials

To accomplish the test, they produced a standard test slab in each of these materials and processes, which I suppose is easy to do when you have so many industrial 3D printers at your disposal:

-

SLS Nylon 12

-

SLA Acc. 60

-

Carbon DLS FPU

-

FDM Orange ASA

-

HP MJF GF Nylon 12

-

HP MJF Nylon 12

-

Carbon DLS EPX

-

SLA Accura Xtreme

-

Carbon DLS UMA

![Xometry’s test rig, showing the print sample with bolt attached for weight [Source: Xometry]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050937e6ce.jpg)

These each had a bolt attached (as shown above) and were mounted on a standard reciprocating saw. The saw oscillates at a very high rate, causing the sample (and bolt) to swing back and forth at tremendous speeds. This is a type of test I hadn’t seen previously, but would be of use to certify materials for use in certain mechanical situations.

The question was, which of the prints would survive a two minute exposure? There’s a clue at the top, but it is quite interesting to hear Xometry’s analysis, as provided by their Director of Application Engineering, Greg Paulson, who looks at why each of the samples failed or survived the test.

Three of the samples failed almost immediately, demonstrating they are definitely not suitable for this type of vibratory exposure. But the remainder all survived and the results might not have been what you expected.

It’s worth a view and takes only a few minutes to watch.

Via Xometry

They really should have tested a range of frequencies, since all the materials have different stiffness.

Some of the materials would have been close to their resonant frequency while others very far from it.