![VELO3D’s new 1-meter Sapphire metal 3D printer [Source: VELO3D]](https://fabbaloo.com/wp-content/uploads/2020/05/Velo3d_Large_Sapphire1meterZheight_img_5eb0653285e36.jpg)

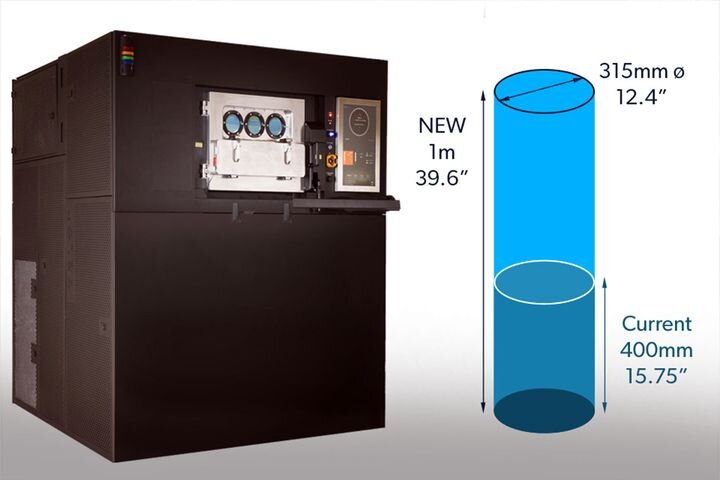

VELO3D’s new 1-meter Sapphire metal 3D printer [Source: VELO3D]

VELO3D surprised with the sudden announcement of a new tall version of their powerful metal 3D printer.

The California-based company has earned a good reputation with their Sapphire 3D printer. This device is able to 3D print metal using a powder bed / fusion process that is tuned and managed in real time so precisely that they often don’t require support structures.

The absence of support structures is an incredible advantage because their presence in a 3D print job means the thermal flows are made that much more complex. Typically engineers setting up the print jobs must carefully design the part’s orientation and structures to minimize the warping effects generated by the extreme heat flowing through the part and support structures.

Additionally, if there are no (or few) support structures, there is no (or less) labor required to remove the support structures. Unlike thermoplastic 3D prints where support structures more or less pop off, metal support structures must be sawn off using precision cutting gear, sometimes with expensive 5-axis CNC equipment.

Sapphire 3D Printer

VELO3D’s initial 3D printer, the Sapphire, included a cylindrical build volume of 315mm diameter with a height of 400mm. This build volume is certainly large enough for many commonly produced metal parts.

I’ve seen many samples made on the Sapphire and I am always impressed with the incredible print quality. The Sapphire’s closed loop control systems allow for extremely fine 3D prints, including this amazing example:

![Sample metal bottle opener made on a Sapphire metal 3D printer from VELO3D [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/velo3d-opener-side-1_img_5eb06532ce8d9.jpg)

Sample metal bottle opener made on a Sapphire metal 3D printer from VELO3D [Source: Fabbaloo]

VELO3D is able to achieve these fine resolutions with a standard powder bed / fusion approach due to the rigorous nature of their componentry and real time system tuning.

1 Meter Sapphire

This week VELO3D announced plans to launch a “one meter next generation” version of the Sapphire later this year. They say the as-yet-unnamed model will be the “world’s tallest production metal-powder laser additive manufacturing system.”

The specifications for the new device are essentially identical to the original Sapphire 3D printer, with the sole exception being the build height. The new build volume will have a 315mm diameter, but a height of 1000mm. It’s expected the same high print quality and reliability will be found on the new device.

VELO3D has not announced the price of this device, which is likely to take a place beside the original Sapphire machine as an option for clients requiring a larger build volume.

Why One Meter Build Volume?

They say necessity is the mother of invention, and that seems to be the case here. VELO3D’s announcement prominently mentions their first client for the new device, Knust-Godwin, a large provider of precision machine services to industry. It’s thought that the new machine would be used to produce larger metal parts for aerospace, automotive and oil & gas industries. All those industries definitely have parts of this size, and could be a good market for VELO3D.

VELO3D explains that Knust-Godwin is specifically interested in producing an oilfield part of this size that presently requires no fewer than five separate subtractive processes to produce. That type of production is not only time consuming, but also quite wasteful of material and human supervision. The ability to 3D print the part in a single job should be vastly more efficient.

There are metal 3D printers with larger build volumes, but none seem to be as tall as VELO3D’s new offering. While you might think you could simply re-orient a part sideways to 3D print it on an alternative device with a wider build volume, that would introduce a large amount of support structures that, as described above, would make the process less efficient. Printing vertically could be quite beneficial in many cases.

For VELO3D, this might have been a natural step, as many 3D printer manufacturers add to their product shelf by producing “stretch” versions of successful products. In a 3D printer this is done by extending the motion system axes and rearranging & resizing surrounding components. It’s definitely not as complex as building a whole new machine, and has the added value of continuing the good features of the original device.

I’m interested to see when VELO3D’s competitors announce similar tall 3D printers.

Via VELO3D